Note: This procedure applies to the front and rear differential gear seals.

1. Loosen the wheel nuts, jack up the rear or front (for rear and front differential respectively) part of the car and install special supports. Block the wheels on the supporting surface to prevent the vehicle from rolling off the supports. Remove the wheels.

2. Disconnect the driveshaft from the differential gear and secure it outside the working area (see subsection 3).

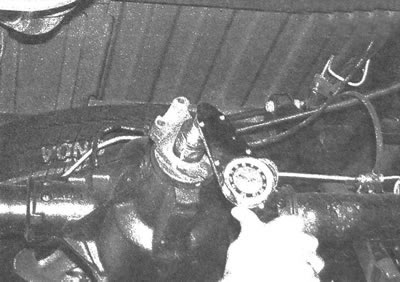

3. Turn the gear several times by hand. Measure the torque required to turn the gear using a torque wrench (see illustration). Record the resulting torque value for use later in the procedure.

9.3. Using a torque wrench, measure the torque required to turn the differential gear

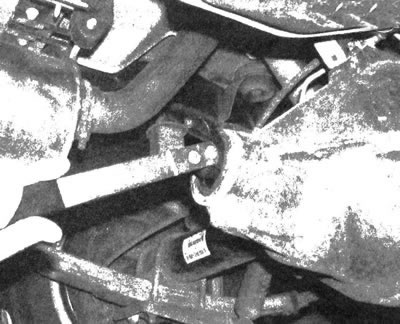

4. Mark the original position of the gear flange and shaft (see illustration), then count and record the number of threads visible on the gear shaft.

9.4. Before loosening the nut, mark the original alignment of the flange and shaft, and also count the number of visible threads

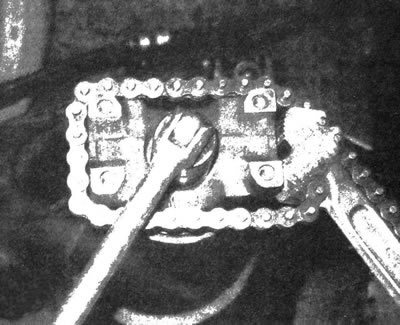

5. Using a special device (available for free sale) It is possible to prevent the differential gear flange from turning when the tightening force of the self-locking nut is loosened. You can also use a chain tool to secure the flange (see illustration).

9.5. When loosening the nut, you can use a chain tool to secure the flange

6. Unscrew the gear nut.

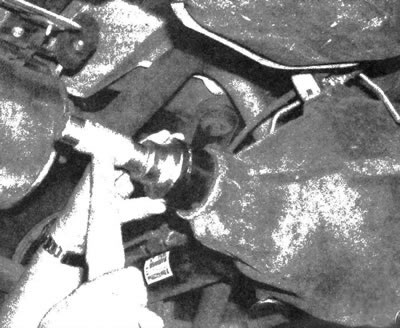

7. Remove the flange. Removal may require the use of a two-jaw puller that attaches to the flange at the rear. Do not attempt to remove the flange by prying it or hitting it or the end of the gear shaft with a hammer.

8. Remove the old oil seal and discard it (see illustration).

9.8. Using a special puller or a large screwdriver, remove the oil seal located on the differential gear shaft (in this case, the gear should not be allowed to shift)

9. Lubricate the seal of the new oil seal and fill the space between its lips with wheel bearing grease, then, without allowing distortion, insert it into the socket using a special mandrel or a large-diameter socket (see illustration). Make sure the seal is installed straight into the housing and to its full depth.

9.9. To insert a new gear oil seal into the differential housing, you can use a socket with a large diameter equal to the outer diameter of the oil seal

10. Aligning the pre-applied marks (see point 4), install the gear shaft flange. If necessary, tighten the gear nut to place the flange in its original location. Do not attempt to drive the flange in with a hammer.

11. Treat the ends of the spline grooves visible in the center of the flange with RTV sealant to create a seal to prevent transmission oil leakage.

12. Install the sealing washer and new gear nut. Tighten the nut until the marked number of visible threads remains the same (see point 4).

13. Measure the torque required to turn the gear and carefully tighten the nut in small increments (no more than 7 Nm), bring it into compliance with the value, the obtaining of which is described in point 3. Taking into account the allowance for attracting the new oil seal, tighten the nut so that the torque required to rotate the gear slightly exceeds the marked value (no more than 0.5 Nm).

14. Install in reverse order all the elements removed during this procedure. Tighten all fasteners to the required torques.