Removal

1. Loosen the wheel nuts, jack up the car and install special supports. Remove the wheel.

2. Remove the protective panel located on the underside of the car (see chapter 11).

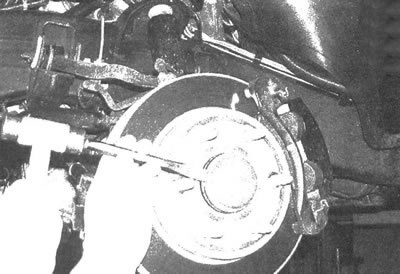

3. Pry up and remove the hub cap (see illustration).

12.3. To knock the cap off the hub, you need to use a hammer and chisel

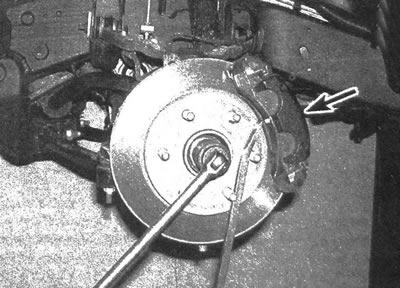

4. Remove the hub/driveshaft nut, which can be discarded afterwards. Wedge a pry bar between the wheel studs to prevent the hub from turning (see illustration). You can also lock the hub by inserting a long tool or screwdriver through the caliper window and inserting the tool into the disc cooling blades.

12.4. Wedge a pry bar between the wheel studs to prevent the hub from turning; you can also block the hub by inserting a screwdriver through the window (marked with an arrow) and inserting the tool into the disc cooling blades

Warning: The hub nut cannot be reinstalled. When installing the drive shaft, a new nut must be installed.

5. Disconnect the wheel speed sensor connector and release the wire from the holders. Unscrew the brake hose holder bolt located at the junction of the metal brake pipe and the frame element (see chapter 9).

6. Remove the shock absorber (see chapter 10).

7. Remove the steering knuckle (see chapter 10), while pulling the drive shaft protrusion out of the hub.

Note: If the drive shaft tab is stuck in the hub, knock it out using a hammer and a brass punch. If this does not disconnect the shaft, use a puller.

8. Using a hammer and brass punch, remove the inner end of the drive shaft from the differential or countershaft. Place the barb against the drive shaft inner CV joint housing. Apply sufficient force to disengage the snap ring located on the inner end of the drive shaft from the differential or countershaft. Disconnect the drive shaft from the differential.

Installation

9. Installation is carried out in the reverse order of removal, performing the following.

10. Before installing the drive shaft, lubricate the outer spline with multi-purpose grease.

11. Install the new hub/driveshaft nut and tighten it to the specified torque.

12. Tighten the fasteners of the suspension elements to the torques specified in Chapter 10.

13. Tighten the wheel nuts to the torque shown in Chapter 1 specifications.