Removal

1. Loosen the rear wheel nuts. Raise the rear of the car with a jack and install supports. Place chocks under the front wheels. Remove the wheel and brake disc (see chapter 9).

2. Remove the differential cover and drain the oil into a previously placed container.

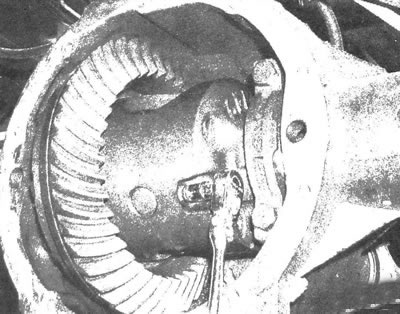

3. Remove the differential gear shaft clamp bolt (see illustration).

6.3. Remove the differential gear shaft clamp bolt

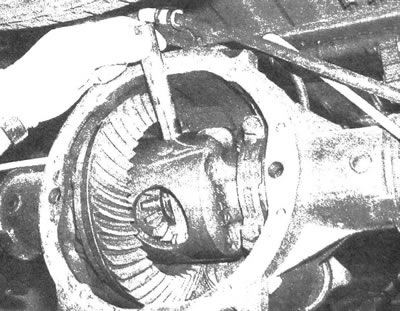

4. When performing the procedure on a car with a conventional differential design (without locking function) the gear shaft must be removed. If the differential has a locking feature, extend the pinion shaft and rotate the differential until the shaft contacts the housing to allow clearance to remove the locking clips (see illustration).

6.4. Pull out the gear shaft to expose the locking brackets (do not turn the axle shafts after pulling the shaft, as this will cause the crosspiece to shift from its original position)

5. Have an assistant press in the outer flange end of the drive shaft and remove the retaining clip located in the groove of the inner end of the shaft (see illustration).

6.5a. Push in the axle shaft flange, then remove the retaining clip located on the inner end of the drive shaft

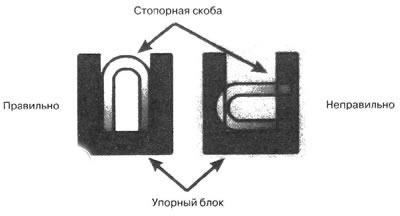

Note: If the differential has a locking feature, use a screwdriver to turn the bracket so that the open part is facing inward (see illustration).

6.5b. On vehicles with a differential that has a locking function, before removing the bracket, it must be positioned as shown

6. After removing the bracket, remove the axle shaft, avoiding damage to the oil seal (It should be noted that every time when removing the axle shaft, it is advisable to replace the oil seal without fail see subsection 7). On some models, the differential is equipped with a thrust washer. When removing the axle shaft, do not allow the washer to fall out.

Installation

7. Carefully insert the axle shaft into the housing and securely connect it to the differential.

8. Place the locking bracket in the groove of the drive shaft and pull out the flange until it locks.

9. Insert the gear shaft, align its hole with the hole in the clamp bolt, and insert the bolt.

Note: Before installation, coat the bolt threads with a special anaerobic compound.

Tighten the clamp bolt to the required torque.

10. Inspect the cover gasket. If the condition is satisfactory, the existing gasket may be installed. If the gasket is faulty, replace it. Install the cover and tighten its bolts to the required torque, then fill the differential with oil, the type of which is indicated in Chapter 1.

11. Install the brake disc, caliper bracket and caliper. Tighten the fasteners to the torques given in Chapter 9. Install the wheel and its nuts. Lower the vehicle and tighten the wheel nuts to the torque shown in Chapter 1 specifications.