Note: Before necessary replacement of CV joint boots, analyze the various restoration options. It is recommended to replace the drive shaft with a remanufactured axle shaft, which can be purchased through the exchange fund of the branded service network - this will significantly reduce the waste of time and possibly help save money. Regardless of the chosen recovery path. Before disassembling, find out about the cost and availability of spare parts.

1. Remove the drive shaft (see subsection 12).

2. Clamp the drive shaft in a vice with fabric pads, the presence of which prevents damage to the axle shaft. Check the radial movement of the CV joint. The presence of excessive movement indicates wear of the hinge parts. Make sure that the hinges move smoothly in all possible directions. If the cover is torn, disassemble the hinge and inspect its elements - they may be excessively worn as a result of a lack of lubrication or foreign particles entering the CV joint.

Note: some models are equipped with a protective cover, which is fixed on each cover on the side with a larger diameter.

Using diagonal cutters, cut the clamps, then pull the casing off the cover.

Inner CV joint

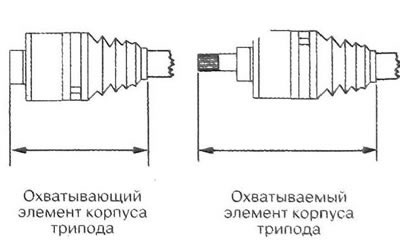

3. When replacing the inner CV joint boot, you must be guided by the accompanying illustrations (see illustrations 13.3a-13.3t).

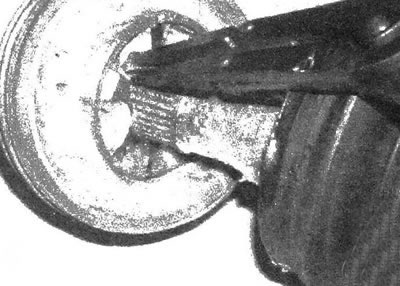

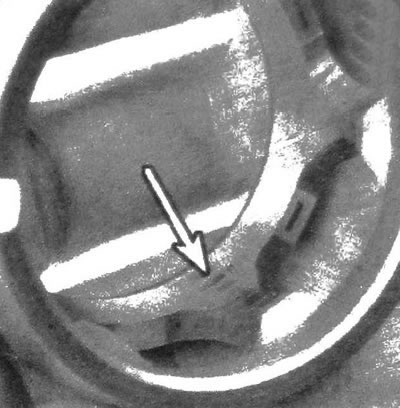

13.3a. Using diagonal cutters, cut the cover clamps (The small diameter clamp has a clamping lock: this clamp can be cut using a hand-held power tool with a grinding disc; When assembling, you should install a clamp of a conventional design, since installing a clamp with a clamping lock requires the use of a special device)

13.3b. Pull the housing off the tripod

13.3s. Pull the boot towards the center of the drive shaft

13.3d. Spread the ends of the retaining ring apart and pull it towards the center of the drive shaft

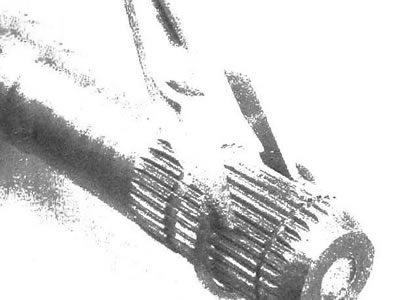

13.3f. Pull back the tripod to expose the locking ring; pry up and remove the ring

13.3f. Carefully knock the tripod off the drive shaft using a brass punch (Do not apply strong blows to prevent the tripod from flying off, as this may cause the needle bearings to crumble

13.3g. When retracting the drive shaft tripod, you must hold the bearing with your hand in its original location; it is preferable to tape the bearing with adhesive or fabric tape to the tripod

13.3h. Pull the cover along with the retaining ring off the drive shaft

13.3i. Clean all old grease off the tripod and housing, then remove each bearing one at a time

13.3j. Carefully disassemble each section of the tripod, clean the needle bearings in solvent and inspect the rollers, tripod, bearings and hinge housing for wear, signs of pitting and other defects

13.3k. Apply special grease to the inner surface of the bearings to glue the needle bearings, then pull the outer races onto them

13.3l. Cover the drive shaft splines with duct tape to prevent damage to the boot, then slide the smaller clamp and boot onto the drive shaft

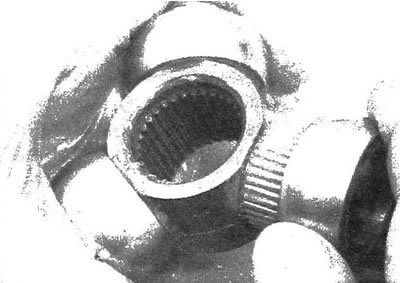

13.3m. Pull the tripod retaining ring onto the drive shaft by moving it past the mounting groove

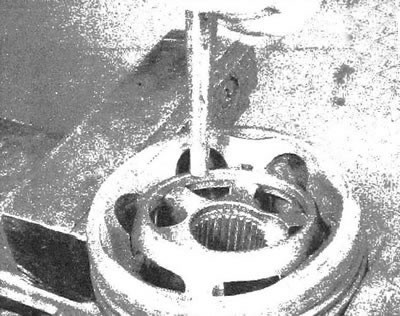

13.Зn. Install the tripod bearings by turning the grooves in the countersink hole towards the end of the shaft

13.Zo. Install the retaining ring, then pull it towards it with a tripod and seat the ring in the groove

13.3p. Fill the joint body with half of the grease supplied with the repair kit, and place the rest in the case

13.3q. By placing the clamp in its original location (without tightening it), install the tripod body

13.3r. Place the boot into the housing and into the drive shaft oil seal groove, then adjust the joint length to the specifications given in this chapter

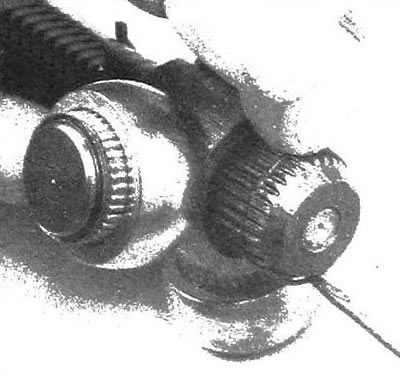

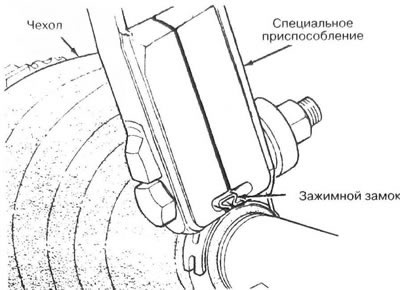

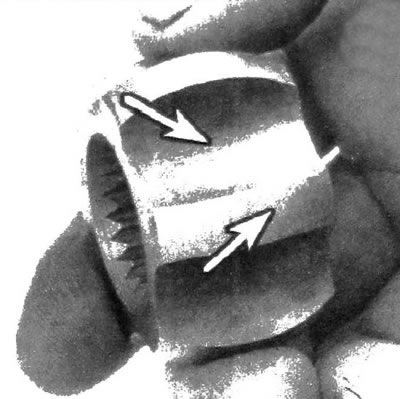

13.3s. After adjusting the hinge length, insert a small screwdriver between the case and the body to remove excess air (make sure there is no deformation of the cover)...

13.3t... then secure the clamp using the special tool (which is available for free sale)

Outer CV joint

4. When replacing the outer CV joint boot, you must be guided by the accompanying illustrations (see illustrations 13.4a-13.4r).

13.4a. Using diagonal cutters, cut the cover clamps (the small diameter clamp has a clamping lock; this clamp can be cut using a hand-held power tool with a grinding disc; When assembling, you should install a clamp of a conventional design, since installing a clamp with a clamping lock requires the use of a special device)

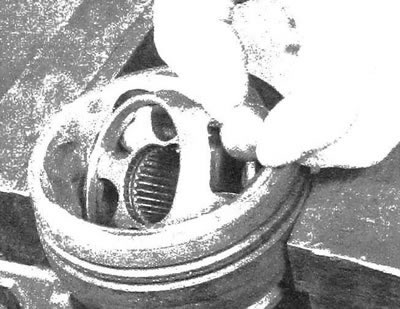

13.4b Separate the ends of the inner snap ring, then pull the CV joint off the drive shaft

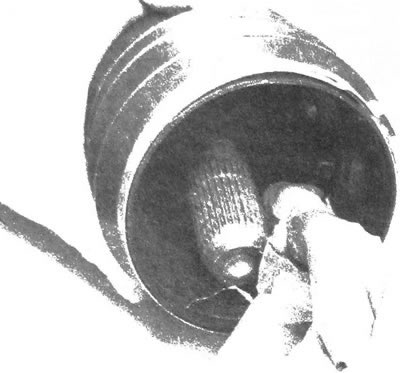

13.4s. Press the inner race down enough to remove, rotate the race with your fingers, and gently tap it and the cage using a hammer and brass punch

13.4d. Pry and remove the balls from the separator one by one

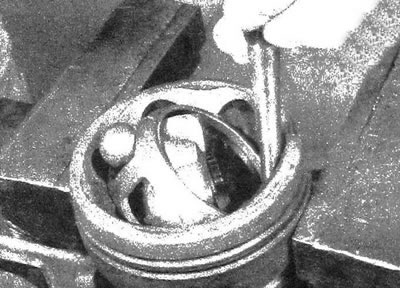

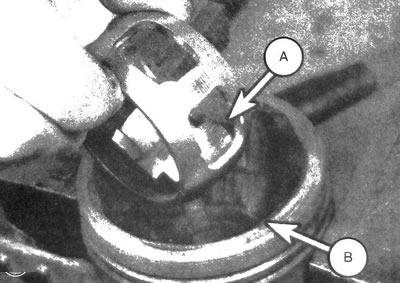

13.4e. Rotate the inner race and cage 90°, then align the cage windows (A) with grooves in the body (IN) and, turning the inner race and separator up, remove the elements from the body

13.4f. Align the grooves of the inner race with the separator windows, then rotate the inner race and remove it from the separator

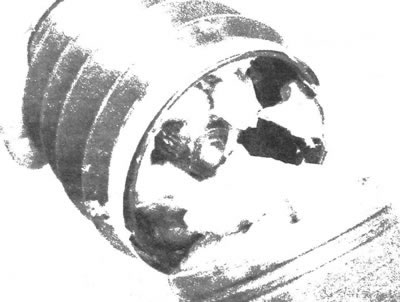

13.4g. After cleaning the elements in solvent, inspect the grooves and depressions of the inner race for signs of pitting and material wear

13.4h. Inspect the separator for cracks, as well as signs of pitting and material depletion; the presence of polished spots on working surfaces is not a defect

13.4i. Rotate the inner race and cage 90°, then place the elements into the housing

13.4j. Turn the elements by gently hitting them with a hammer and a copper bit...

13.4k...then press all the balls into the separator windows one by one

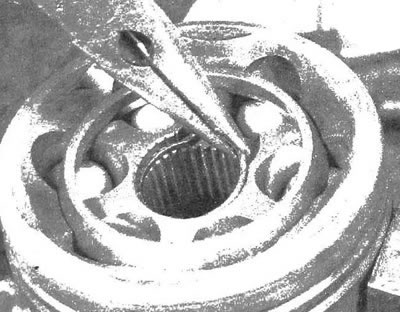

13.4l. Using needle-nose pliers, place a new snap ring in the groove...

13.4m...then shrink the ring using special pliers

13.4n. Place grease into the spline hole of the hinge, then insert a wooden cylinder there (the diameter of which is slightly less than the diameter of the drive shaft) and push the lubricant into the hinge; perform the operation until the joint is filled with lubricant

13.4o. Install the smaller clamp and boot onto the drive shaft, then fill the boot with grease...

13.4 rub....so that its level reaches the end of the drive shaft

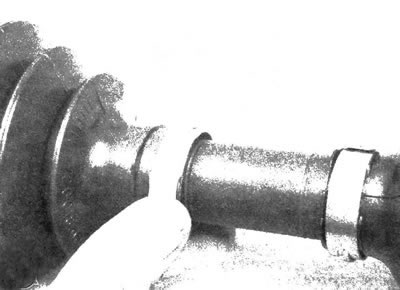

13.4q. Place the CV joint on the drive shaft, aligning the splines, then, using a hammer with a soft hammer, tap the joint onto the shaft until the snap ring fits into the groove

13.4r. Place the inner end of the boot in the groove and install the clamp, then perform a similar operation on the other end of the boot; tighten the clamps using the special tool (see illustration 13.3t)