Removal

Caution: it is necessary to remove the box without separating the torque converter from it. If the torque converter is left connected to the drive disc, damage to the torque converter drive disc, pump bushing, and oil seal may occur. The drive disc is not designed to support the load, so do not allow the weight of the transmission to concentrate on the disc when removing it.

1. Disconnect the negative battery cable.

2. Raise the vehicle and install vertical supports. If necessary, remove the protective panel and its jumper.

3. Drain transmission oil (see chapter 1).

4. Disconnect the transmission oil fill pipe located on the right side of the engine.

5. Remove all elements of the exhaust system that interfere with the removal of the box (see chapter 4). Remove the EVAP canister from its bracket located inside the left frame side member and move it to the side without disconnecting the hoses. Also remove the fuel tank insulation shield.

6. Remove the rear driveshaft (see chapter 8).

7. Support the engine with a hydraulic jack. Place a wooden block under the pallet.

8. Support the gearbox with a hydraulic jack (It is preferable to use a special jack, which can be rented). Attach the box to the jack with special chains.

9. Unscrew the nuts that secure the box support to the body crosspiece (see illustration 7.4a). Lift the box slightly and remove the jumper.

10. Lower the engine and transmission until the top and sides of the transmission are within reach.

11. When performing the procedure on all-wheel drive models, it is necessary to remove the transfer case (see chapter 7B).

12. Disconnect the selector cable from the mechanical lever (see subsection 3).

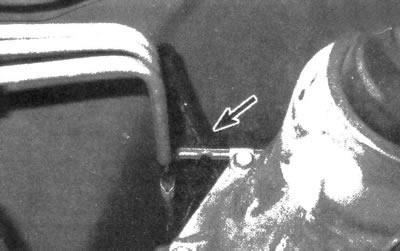

13. If necessary, remove the transmission heat shield and disconnect the ventilation hose (see illustration).

8.13. Disconnect the ventilation hose from the gearbox (marked with an arrow)

14. Performing the procedure on the left side of the transmission, disconnect the Park/Neutral switch electrical connector (see subsection 5), as well as the main wiring connector. Also disconnect the transmission wiring harness from any fasteners. Remove the bolt from the fuel supply pipe bracket attached to the transmission on the left.

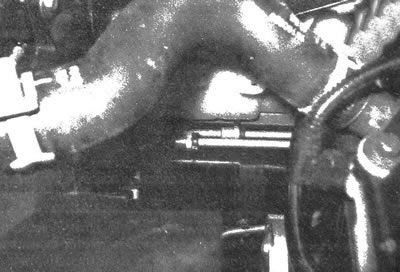

15. Remove the inspection plug located at the base of the box casing and mark the original position of the torque converter and drive disc (see illustration).

8.15. Pry up and remove the inspection plug and mark the original relationship between the torque converter and the drive disc

16. Unscrew the bolts securing the torque converter to the drive disk. Turn the crankshaft only in a clockwise direction (when viewed from the front).

17. Disconnect the transmission cooler lines connected to the right side of the transmission and engine (see illustrations). To disconnect the coolant line from the box, simply remove the plastic ring and pry up the quick release clamp. Plug the lines to prevent coolant from leaking after disconnection. Before installation, inspect the O-rings of the transmission cooler lines.

8.17a. Disconnect the coolant lines from the transmission...

8.17b....and from the engine

18. Attach the box to the jack with a safety chain and unscrew the bolts securing the box to the engine (see illustration). It is recommended that this operation be performed using an articulated extension arm.

8.18. Unscrew the gearbox housing bolts (bottom left corner of box shown)

Note: the top bolts are easier to remove once the box is lowered (see next point).

19. Lower the transmission and engine slightly and remove the oil fill tube/dipstick bracket bolt. Pull the tube out of the gearbox. Don't lose the tube seal (if there is no damage, it can be used for further operation).

20. Attach a clamp to the transmission housing by threading it through the lower inspection hole. The clamp must go in front of the torque converter, behind the drive disc. This will prevent the torque converter from falling off when removing the transmission. Move the box rearward to disengage it from the cylinder block mounting pins and ensure that the torque converter has disengaged from the drive shaft. Lower the box with a jack.

Installation

21. Before installation, make sure that the torque converter is securely connected to the pump. If the fluid coupling was removed, apply a small amount of transmission fluid to the rear hub of the torque converter, on the surface in contact with the front transmission seal. Install the torque converter in front of the transmission input shaft. When installing, you must turn the torque converter from side to side. Thus, the fluid coupling must connect to the front pump of the automatic transmission. To make sure the torque converter connection is secure, place a ruler against the engine-transmission interface. Make sure the torque converter lugs are at least 19mm below the ruler. Reinstall the clamp to secure the torque converter in position.

22. Jack up and place the attached transmission in its original location.

23. Rotate the torque converter to align its holes with the drive disc holes. In this case, the marks, the application of which is described in paragraph 15, must be aligned.

24. Carefully move the box forward until the dowel pins connect to the torque converter. Make sure. that the box is adjacent to the engine without any gap. If there is a gap, make sure that there is no wire or other element pinched between the units. Also make sure that the connection between the torque converter and the front transmission pump is secure. Try to turn the torque converter - if it does not feel easy, the torque converter may not be fully connected to the pump. If necessary, lower the box and install the torque converter correctly.

25. Install the dipstick tube and its seal into the box casing. Install and securely tighten the engine mounting bolts. When tightening the bolts, make sure that the transmission fits evenly to the power unit. If uneven fit of the units is detected, determine the cause. It is forbidden to tighten the box with the engine when tightening the bolts - this may crack the box casing.

26. Lift the back of the box and install the support bar.

27. Remove the jacks that supported the engine and gearbox from under the car.

28. Install the bolts securing the torque converter to the drive shaft. Tighten the fasteners to the required torque.

Note: All fasteners must be installed before tightening bolts.

29. Install new retaining rings onto the coolant line quick release couplings.

Note: Do not pull the fastening rings onto the couplings. Instead, you should hook one end of the retainer into the slot in the coupling and rotate the other end of the ring, inserting it into the other slot. If the retaining ring does not install as described, it may have become loose and is no longer suitable for reliably connecting the coolant lines. Connect the lines to the couplings and snap the connectors into place. Pull the plastic caps onto the couplings.

30. Connect the transmission electrical connectors and install the heat insulation shield.

31. Connect the selector cable (see subsection 3).

32. Install the torque converter service cover.

33. If necessary, install the transfer case (see chapter 7B).

34. Install the driveshaft (s) (see chapter 8).

35. Adjust the selector cable (see subsection 3).

36. Install and connect all exhaust system elements (see chapter 4).

37. Remove the supports and lower the vehicle.

38. Fill the transmission with the appropriate type of transmission fluid (see chapter 1), start the engine and check for leaks.