Warning 1: The air conditioning system is under high pressure. Do not loosen couplings or remove components without first discharging the system when contacting a branded or specialized service station. Disconnecting the air conditioning system couplings should be done while wearing safety glasses or a mask.

Warning 2: When performing routine inspection and maintenance of the fuel system, certain precautions should be observed. Work in well-ventilated areas, and do not allow open flames or light bulbs without a protective hood in the work area. Do not allow gasoline to come into contact with your skin; wear rubber gloves. If gasoline gets on your skin, wash it off with running water and soap. Immediately wipe up spilled fuel and store any cloth that has absorbed it so that it does not ignite. Before influencing fuel system components, release residual pressure (see chapter 4). Have a Class B fire extinguisher on hand and wear safety glasses or a mask.

Warning 3: The vehicles described in this manual are equipped with a passive restraint system (SRS), also known as an air spring system. Before carrying out work in the area where the elements of this system are located, you should turn off its power, since accidental deployment of the airbags can result in serious injury (see _ chapter 12).

Removal

1. Contact a branded or specialized service station to discharge the air conditioning system.

2. Release residual pressure in the fuel system (see chapter 4). Disconnect the cable from the negative terminal of the battery.

3. Cover the fenders and the panel located under the windshield, then remove the hood cover (see chapter 11). There are special pads available to protect the wings, but for this purpose it is quite acceptable to use an old blanket or bedspread.

4. Remove the air cleaner (see chapter 4). Drain the coolant.

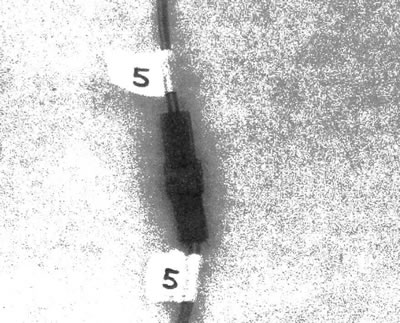

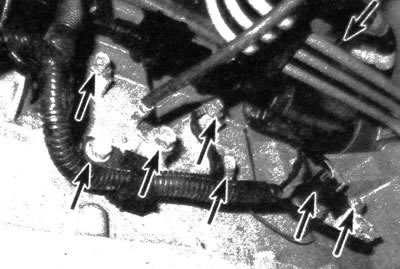

5. To ensure proper connections during subsequent reassembly, attach identification tags to the vacuum and exhaust hoses, electrical connectors and ground wires, and fuel lines that will be disconnected during engine removal, then disconnect (see illustrations). If there is a possibility of confusion, make a sketch or photo of the engine compartment and clearly mark the hoses, tubes and wires on it. Disconnect the corresponding brackets from the engine and move the wiring harness aside.

7.5a. Attach identification tags to the wires before disconnecting

7.5b. A variety of grounding bars, brackets and electrical connectors are attached to the cylinder block (left rear side of engine shown)

Note: Some wiring may be easier to disconnect when jacking up the vehicle and installing vertical supports.

6. Mark and disconnect the cooling system hoses from the engine. It is also necessary to disconnect the heater hoses from the heat exchanger pipes located on the rear partition of the engine compartment (see illustration).

7.6. Disconnect the heater hoses from the heat exchanger

7. Remove the manifold absolute pressure sensor (IDA).

8. Remove the throttle block (see chapter 4).

9. Disconnect from condenser and filter drier (see warning at the beginning of this subsection).

10. Remove radiator (see chapter 3).

11. Remove the drive belt (see chapter 1) and unscrew the bolts that secure the power steering pump (see chapter 10). Place the pump aside and tie it with a piece of wire.

12. Unscrew and remove from the engine the nut that secures the tube bracket for filling the automatic transmission with oil.

13. When performing the procedure on an all-wheel drive vehicle, it is necessary to disconnect the front axle wiring connector.

14. Unscrew the bolt that secures the bracket for the hydraulic lines of the automatic transmission on the right side of the engine, then move the lines away from the power unit.

15. Remove the electronic PCM unit (see chapter 6).

16. Raise the vehicle and install vertical supports. When performing the procedure under the vehicle, drain the engine oil (see chapter 1).

17. If performing the procedure on a four-wheel drive vehicle, it is necessary to remove the engine skid plate, front drive shafts and front driveshaft (see chapter 8). Also, if necessary, remove the fuel tank protection plate.

18. Disconnect the exhaust pipe from the manifold (see chapter 2A) and pull it back.

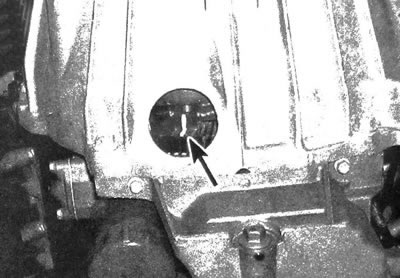

19. Remove the service cover, mark the original relationship with the drive disk, then unscrew the torque converter bolts (see illustration).

7.19 Mark the original position of the torque converter and the drive disk, then unscrew

20. Support the gearbox with a floor jack.

Note: A block of wood must be placed between the jack and the transmission housing.

21. Remove the transmission jumper (see chapter 7A).

22. There are four bolts on top of the box casing. To ensure there is enough space to remove these bolts, the transmission must be lowered sufficiently. Disconnect the engine wiring harness from two of these bolts and remove all four bolts. After this, lift the box and install its jumper, securing this element with only two bolts.

23. Remove the remaining transmission housing bolts.

24. Unscrew the nuts of the lower engine mounts.

25. Lower the car and unscrew the nuts of the upper engine mounts. Support the gearbox with a floor jack.

26. Connect the lift chain to the mounting bracket located on the front of the engine (see illustration). Connect the other end of the chain to the rear right corner of the engine; unscrew the exhaust manifold bolt and, installing in its place another, longer bolt with the same diameter and thread pitch, attach the chain to the cylinder head (see illustration).

7.26a. Connect the winch chain to the mounting hook located on the front of the engine...

7.26b...and also to the rear right corner of the cylinder head (attach the chain with a bolt longer than that of the unscrewed fastener; if necessary, place a washer). It is also possible to wrap a chain around one of the channels and secure it with a bolt.

Caution: DO NOT lift the engine by the intake manifold. Lift the power unit by the cylinder head or cylinder block only.

27. Roll up the winch and connect the chain to it. Tension the chain, but do not lift the engine yet.

Warning: Keep body parts away from the engine, which is supported only by a winch or other lifting device.

28. Raise the engine slightly. Carefully push the engine forward to disengage it from the transmission. Do not allow the torque converter to be disconnected from the transmission (secure the torque converter by placing a pair of clamps on the box casing). Slowly lift the engine and remove it from the engine compartment (see illustration). Make sure that no parts are pinched while removing the engine.

7.28. Pull the engine forward as far as possible to clear it from the transmission and away from the body panel located under the windshield, then lift the engine until it is clear of the vehicle body

29. Remove the flywheel/drive discs and mount the engine on a stand.

Installation

30. Install the drive disk on the engine (see chapter 2A). Inspect and replace engine and transmission mounts if necessary.

31. Slowly lower the engine into the engine compartment. In this case, it is necessary to direct it to the supports.

32. Connect the torque converter to the crankshaft as described in Chapter 7A.

33. Install and securely tighten the bolts that secure the engine to the transmission.

Caution: DO NOT tighten the engine and transmission when tightening the bolts.

34. Install the remaining elements in the reverse removal sequence.

35. If necessary, add coolant, engine oil, transmission oil, and power steering fluid (see chapter 1).

36. Start the engine and check that it is operating properly and that there are no leaks of operating fluids. Install the hood cover and test drive the vehicle.

37. Contact a station of the appropriate profile to refill the air conditioning system and check it for leaks