Warning: See warning in subsection 1.

Checking the performance of the fuel pump

1. If you notice poor fuel supply, you must first inspect all fuel lines and make sure that the problem is not due to a leak. Before performing this procedure, make sure that the fuel tank is filled with the correct brand of fuel

2. Apply the parking brake. Have an assistant turn the ignition key to the ON position and listen to the sounds coming from the fuel pump, which is located in the tank. A working pump must turn on to prime the system before starting the engine. To conclude that the pump is operational, it is enough to hear the noise for two seconds. If the pump's functionality is confirmed, check the pressure in the fuel system.

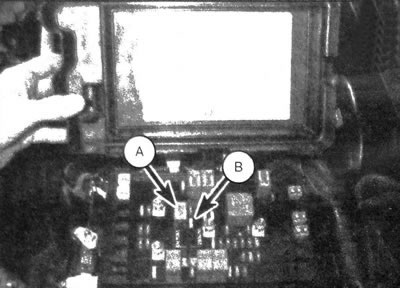

3. If the pump does not make operating noise after turning on the ignition, turn the key to the OFF position and remove the cover of the distribution block located in the engine compartment. Inspect the PCM fuse «IN» 20A, as well as a pump relay (see illustration) (To check, you can install a known good relay instead of the existing fuel pump relay). If the relay and fuse are normal, examine the relay control circuit connecting the junction block to the PCM. If the circuit is working properly, contact a manufacturer's station to diagnose the relay.

3.3. Fuel pump relay location (A) and RSM fuse "IN" (refer to the diagram located under the electrical distribution block cover)

4. If the pump does not turn on, disconnect the connector from the fuel pump in the tank (see subsection 5). Using a test lamp or voltmeter, make sure that voltage is supplied to the gray pin of the connector. Using a continuity tester or ohmmeter, verify the ground continuity at the black terminal of the connector. If it is determined that there is no voltage at the gray contact terminal or a break in the ground loop (on the black pin), replace the wiring harness.

5. If the presence of voltage is confirmed at the gray contact terminal, as well as the continuity of the ground loop, but the fuel pump does not operate when turned on, you will have to replace it (see subsection 7).

Checking operating fuel pressure

Note: To check fuel pressure, you must use a pressure gauge rated for high fuel pressure. The pressure gauge must have an appropriate coupling for connection to the service connection of the system. To check the functionality of the fuel pressure regulator, it is necessary to install a fuel shut-off valve in the fuel return line using the appropriate adapters.

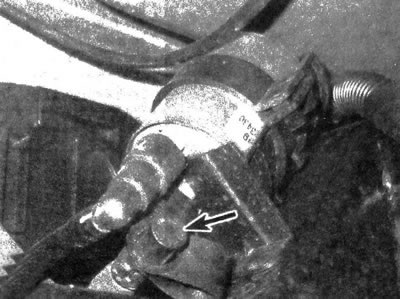

6. Relieve pressure in the fuel system (see subsection 2). Remove the service connector cap and connect the pressure gauge (see illustrations). If the fuel tank has a protective panel, you need to find a service hole in it.

3.6. Location of the service fitting for checking fuel pressure

7. Turn the ignition key to the ON position. The pump should turn on for two seconds and then turn off. Take the pressure gauge reading and compare it with the value specified in the specifications in this chapter. To obtain the highest reading, turn the key from ON to OFF several times as necessary.

8. If the operating fuel pressure is low, turn the ignition key to the OFF position and relieve pressure in the fuel system (see subsection 2). Install into the fuel return line and close the fuel shut-off valve.

Caution: Do not pinch the flexible section of the fuel line, otherwise it may be damaged.

Turn the ignition key to the ON position and measure the fuel pressure.

Caution: do not allow the fuel pressure to rise to 5 atm, otherwise damage to the fuel system elements may occur

If it is now determined that the fuel pressure is higher than normal, replace the pressure regulator (see subsection 13). If the pressure is low, make sure that the passage of the fuel lines and fuel filter is not restricted. If no restriction is found, remove the fuel pump (see subsection 7) and inspect the fuel pickup for blockages. Make sure there is no fuel leaking through the pump flexible tube. Make sure that the pump wires do not have extremely high electrical resistance. If the check does not reveal any problems, replace the pump.

9. If the fuel pressure, the determination of which is described in paragraph 7, is higher than normal, make sure that the patency of the return fuel line is not limited. If the fuel line is not clogged, replace the fuel pressure regulator (see subsection 13).

10. If the pressure is correct, start the engine. When the engine is running, the fuel pressure should be 0.2-0.7 atm. below the value defined in paragraph 7. If this condition is not met, disconnect the vacuum hose of the pressure regulator and make sure that the degree of vacuum in the hose is 305 - 355 mm. rt. Art. If the hose does not create a vacuum, inspect it for blockage or rupture. If vacuum is confirmed, connect the hose to the pressure regulator. If, when creating a vacuum, the fuel pressure in the regulator does not decrease, replace this element.

11. Turn off the engine and observe the pressure change for 5 minutes. In this time period there should not be a decrease in pressure to less than 0.34 atm. If such a decrease occurs, it means that there is a fuel leak through the fuel line, injector, pressure regulator diaphragm. Also, the cause may be failure of the fuel pump control valve. The first check for internal fuel leakage is carried out at the pressure regulator - disconnect the vacuum hose and inspect it for the presence of fuel inside. The walls of the hose may become wet with fuel, or it may begin to leak out. Turn the ignition key from ON to OFF several times and inspect the pressure regulator fitting for any drops of fuel. If there is fuel in the regulator or its hose, replace this element. To check for injector leaks, turn the ignition switch from ON to OFF several times to obtain the maximum pressure reading, then immediately shut off the forward and return fuel lines. If within 5 minutes the pressure drops below 0.34 atm, it means that fuel is leaking through one or more injectors. The leak can also occur through the fuel line or receiver, but in this case the signs will be obvious. If the injectors do not allow fuel to pass through when pressurized, it means that the leak is occurring through the main fuel line, or the fuel pump has failed.

12. Before disconnecting the pressure gauge, the fuel pressure should be relieved (see subsection 2).