Note: The following procedure assumes that the fuel pressure is correct (see subsection 3).

1. Inspect all electrical connectors related to the system. Make sure the circuits are properly grounded. Loose connectors and poor grounding manifest themselves as more serious problems with the engine.

2. Make sure that the battery is fully charged, since proper operation of the control unit and system sensors is only possible if the supplied voltage is correct.

3. Inspect the air cleaner element. A clogged filter will negatively impact engine performance and efficiency (see chapter 1).

4. Inspect the system circuit fuses. If the test reveals a blown fuse, replace it and make sure it does not blow again. If the fuse blows, locate the wire shorted to ground in the wiring harness.

5. Make sure the air intake duct connecting the air cleaner to the throttle body is sealed. Depressurization of the air duct leads to a constant depletion of the air-fuel mixture. Also inspect all vacuum hoses connected to the intake manifold/throttle body.

6. Remove the resonator and air intake duct from the throttle body (see subsection 9). Inspect the throttle body for dirt and all kinds of deposits in the body, paying special attention to the valve. If necessary, clean using a special cleaner, a toothbrush and a cloth.

Caution: Do not clean the throttle body with petroleum solvent, as this may damage the element.

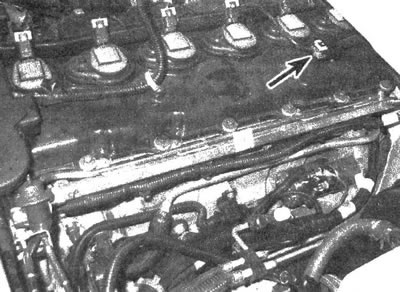

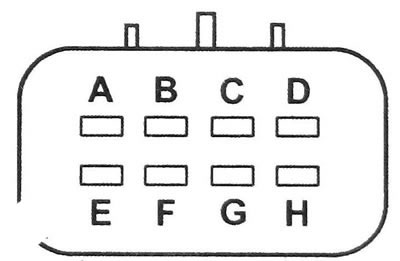

7. Locate the 8-pin connector and disconnect it (see illustration). Determine the resistance of each injector by connecting an ohmmeter to the terminal «A» and the corresponding contact (B, C, D, F, G or H) on the connector on the injector side (see illustration). Compare your results with the values given in the specifications in this chapter. Injectors whose resistance is not up to standard (in on or off position) subject to replacement.

11.7a. Injector wiring harness connector

8. Turn the ignition key to the ON position and determine the voltage at the pink terminal «A» on the connector on the injector wiring harness side (on the engine wiring harness side, it is necessary to measure at the contact terminal corresponding to the contact «A» in illustration 11.7b). If there is no voltage supply from the battery, it is necessary to inspect the corresponding fuse and wire (see _ chapter 12).

11.7b. 8-pin injector harness connector pins (connector on the injector side with the plug disconnected): A. Voltage supply from the ignition system (pink); B. Injector 4 (blue/black); C. Nozzle 5 (black White); D. Nozzle 6 (yellow black); E. Blank pin; F. Nozzle 1 (black); G. Nozzle 2 (light green/black); N. Nozzle 3 (pink black)

9. A description of further testing of the performance of the engine control system is given in Chapter 6.