Warning: Considering the increased flammability of gasoline. as well as the explosiveness of its vapors, certain precautions must be observed when carrying out preventive inspection and maintenance of fuel system elements. Work in well-ventilated areas, and do not allow open flames or light bulbs without a protective cap in the work area. Do not allow gasoline to come into contact with your skin. Wear rubber gloves. If gasoline gets on your skin, wash it off with running water and soap. Immediately wipe up any spilled fuel and store any material that has absorbed it in a place where there is no risk of fire. Before exposing elements, relieve pressure in the system. Have a Class B fire extinguisher ready and use the system with special eye protection.

All described models have a multipoint sequential fuel injection system (SFI) (see illustration). Direct sequential fuel injection into the intake tracts of the cylinders occurs in accordance with synchronized pulses entering the injectors from the electronic unit of the engine control system (RSM). After processing the signals corresponding to the engine parameters, the microprocessor calculates the optimal amount of fuel that is supplied to the intake tracts of the cylinders in a certain sequence.

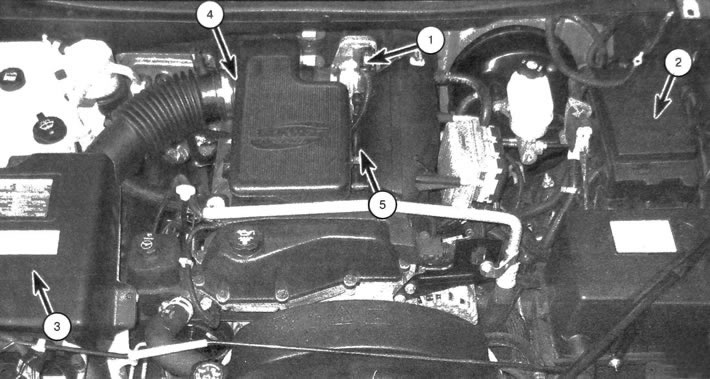

1.1 Elements of a typical fuel system 1. Throttle block; 2. Fuel pump relay (located inside the distribution block, which is located in the engine compartment); 3. Air cleaner housing; 4. Air intake duct and resonator; 5. Fuel receiver and injectors (not visible from this resource)

All models use an electric fuel pump located in the fuel tank. To gain access to the pump, the fuel tank must be removed. The fuel system measuring block is an element of the fuel pump, and is removed using the same method.

The exhaust system consists of exhaust manifolds, catalytic converter, tailpipes and muffler. Each of the listed elements is replaceable. The catalytic manifold is described in chapter 6.