Warning: You must wait until the engine has completely cooled before performing this procedure.

Removal

1. Drain the coolant (see chapter 1).

2. Remove the valve cover (see subsection 4).

3. Remove the exhaust manifold (see subsection 5).

4. Remove the drive chain and sprockets (see subsection 7).

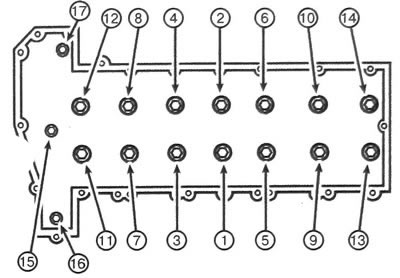

5. Remove the seventeen cylinder head bolts in the reverse order of the tightening sequence (see illustration 9.13).

6. Remove the cylinder head from the engine.

Caution: The cylinder head is a heavy component. When removing, enlist the help of an assistant. If the head is attached to the block, do not insert attachments or tools between the mating surfaces. Instead, pry the socket over the protrusion of the cast body or tap it with a block of wood and hit it with a hammer.

7. Remove the cylinder head gasket.

8. Clean the mating surfaces of the cylinder head and block. Avoid damaging aluminum alloy parts. Don't lose the two locating pins.

9. Examine the surfaces of the block and head using a straight edge and feeler gauges to determine clearances. Compare your results with the values given in the specifications in this chapter.

Installation

Note 1: a prerequisite for performing the procedure is that the first piston is at TDC.

Note 2: The cylinder head bolts need to be replaced.

10. After ensuring that the dowel pins are correctly positioned, place the gasket on the cylinder head.

11. Place the head on the cylinder block.

12. Install and finger-tighten the new cylinder head bolts.

13. Tighten the bolts to the required torque, following the sequence shown (see illustration).

9.13. Head bolt tightening sequence

14. The remainder of the assembly is performed in the reverse order of removal.

15. Change engine oil and filter, as well as coolant (see _ chapter 1).