Warning: The battery emits hydrogen gas, so keep open flames and lit cigarettes away from the battery. When working with the battery, you must wear safety glasses. Immediately wash off spilled electrolyte with plenty of water.

Examination

1. Before measuring the battery voltage, it is necessary to remove its static charge. Turn on the high beams for 10 seconds, then turn off the headlights and leave the car for two minutes. Remove the battery (see paragraphs 4 - 10).

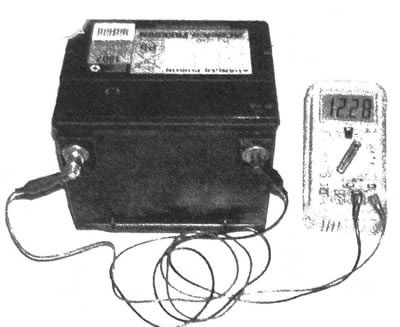

2. Check the battery charge level. The state of charge can be determined by the color of the indicator, which is located on top of the battery. If the indicator is clear, the battery needs to be charged (the procedure is described in chapter 1). After this, check the voltage with a voltmeter (see illustration). Connect the negative lead of the digital voltmeter to the negative terminal of the battery and the positive lead to the positive terminal of the battery. The voltage must be at least 12.4V. If the voltage obtained is less than specified, fully charge the battery before performing a load test.

3.2. To check the open circuit voltage of the battery, you must connect a voltmeter. When the battery is fully charged, the voltage should be at least 12.4V (this value depends on the outside temperature)

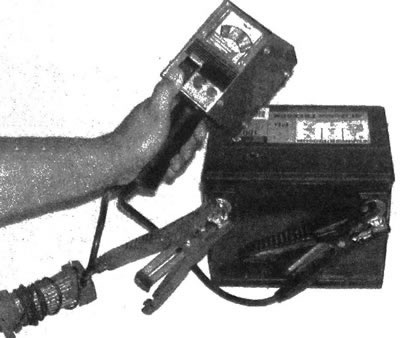

3. Perform a load test. A quality check can only be performed using a load fork, which can be purchased at most automotive stores. This test determines the battery's ability to maintain the required voltage when the starter and other energy sources are turned on. Connect the load plug to the battery terminals (see illustration). Check according to the plug's instructions. This plug uses a carbon element to increase the load on the battery. Apply a load to the battery and make sure its voltage does not drop below 9.6V within 15 seconds. An unsatisfactory battery condition is easily detected when using a load fork.

3.3 Connect the load plug to the battery terminals and test according to the instructions for using the plug

Note: When testing in cold conditions, a slight allowance is made for the lower voltage limit. This is usually reflected in the tables contained in the instructions accompanying the load fork. The minimum voltage limit specified for an ambient temperature of 0°C is 9.1 V.

Replacement

4. Disconnect the negative cable from the battery.

5. Disconnect the positive battery cable.

6. If the design provides for heating the engine block, then it is necessary to disconnect the heater wire holder located on the battery.

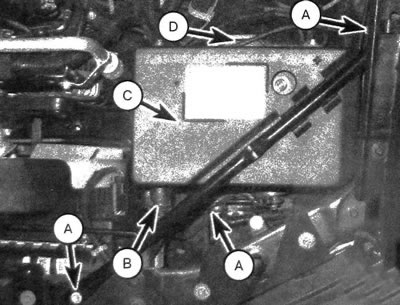

7. Unscrew the support beam bolts from the battery casing and disconnect the ventilation tube (see illustration).

3.7. Before removing the battery, unscrew the bolts (A) and remove the supporting beam, and also disconnect the ventilation pipe (IN), remove the battery cover (WITH), then unscrew the bolt and remove the holder (D)

8. To remove, lift the battery cover vertically upward.

9. Unscrew the nut and remove the battery holder.

10.To remove, lift the battery vertically upward.

11. If there is corrosion deposits on the pan, it is necessary to remove it and clean the corroded areas with a baking soda solution to prevent further spread of rust (see illustration). Paint the repaired areas with corrosion-resistant paint.

3.11. Inspect the battery shelf, holder brackets, and associated fasteners for signs of corrosion or other damage. If necessary, unscrew the bolts (with which the shelf is attached to the inner wing panel) and remove the shelf

12. Clean the battery case and cables and perform maintenance as described in Chapter 1.

13. When replacing the battery, you must make sure that the technical requirements of the parameters of the new battery are met. Make sure the new battery is fully charged before installation.

14. Installation is carried out in the reverse order of removal. First of all, you need to connect the positive wire, and then the negative one.

15. After connecting the wires, apply grease or petroleum jelly to the terminals to prevent corrosion.