Warning: The air conditioning system is under high pressure. Do not loosen couplings or remove components without first discharging the system when contacting a branded or specialized service station. Disconnecting the air conditioning system couplings should be done while wearing safety glasses or a mask.

Warning 1: The vehicle air conditioning systems described in this manual use R-134a refrigerant, which is not an environmentally harmful product. System components charged with this refrigerant and the appropriate type of compressor oil must not be exposed to R-12 refrigerant. Mixing two types of refrigerant can damage system components.

Caution 2: when replacing elements of the air conditioning system, it is necessary to add compressor oil in a volume equal to the amount of oil remaining in the removed element. Before adding oil to the system, you must study the instructions to ensure its compatibility with R-134a refrigerant.

1. To ensure and maintain efficient operation of the air conditioning system, the following procedures should be followed during regular maintenance.

- A) Inspect the compressor drive belt. Replace it if necessary (see _ chapter 1).

- b) Check and, if necessary, adjust the tension of the drive belt (see _ chapter 1).

- With) Inspect system hoses for cracks, swelling, hardening, or other signs of wear. Make sure that there is no oil leakage from the hoses and couplings. If the above symptoms are exposed, replace the hoses as necessary.

- d) Inspect the condenser fins for leaves, insect remains, or other debris stuck in them. Clean the plates using compressed air and a soft brush.

- e) Make sure the system is properly charged with refrigerant.

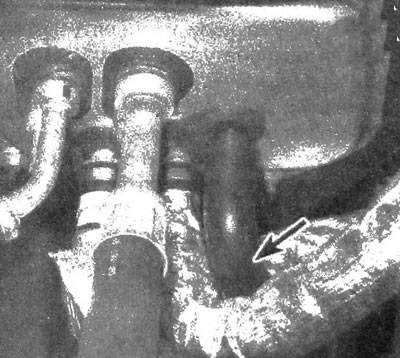

- f) If there is a characteristic noise of water behind the instrument panel, as well as if water leaks are detected on the interior carpet, make sure that the drain pipe of the evaporator housing has sufficient passage (see illustration). To check, insert a piece of wire into the tube.

13.1. Make sure that the evaporator housing drain tube located on the rear bulkhead of the engine compartment is not obstructed. This angle was obtained by pointing the lens at the top of the engine

2. It is highly recommended to turn on the air conditioning system at least once a month for at least 10 minutes. This is especially true in winter, since due to prolonged downtime of the system, irreversible hardening of the internal seals of the system can occur. It should be noted that the air conditioning compressor is turned on in mode «Defrost» (defrosting glass).

3. If problems are detected in the operation of the air conditioning system, it is necessary to continue the procedure, starting with the operations described in paragraph 6, and perform the check described below.

4. Due to the complexity of the system design, as well as the need to use special equipment, diagnostics should be entrusted to a qualified professional. Therefore, this manual does not include descriptions of disassembly and repair procedures - they must be performed at a specialized station. A car mechanic only needs to check the functionality of the drive coupling and determine the degree of contamination of the system with refrigerant. This chapter describes simple checks as well as procedures for replacing components.

5. There is only one reason for a decrease in the efficiency of the system that can be identified and eliminated by a car mechanic - a lack of refrigerant. If system performance decreases due to a refrigerant leak, perform one of the following test procedures to determine the cause.

Checking the degree of contamination of the system with refrigerant

6. Warm up the engine to normal operating temperature.

7. Set the air conditioning control to the minimum temperature position and the fan switch to the maximum speed position. Open the doors (so that the air conditioning system does not turn off immediately after cooling the air in the cabin).

8. Once the engine has reached operating temperature, feel the coolant lines that are connected to the evaporator on the rear bulkhead of the engine compartment.

9. The tube leading from the battery to the evaporator should be cold, and the outlet line of the evaporator (tubes through which the refrigerant returns to the compressor) have a slightly higher temperature (10-15°C warmer). If the evaporator outlet line is significantly warmer than the inlet line, or if the evaporator inlet line is not cold, the system will need to be recharged with refrigerant. Place the thermometer on the dashboard center vent grille and turn on the air conditioning system at maximum efficiency. The temperature of the air leaving the deflector should be 2-5°C lower than the ambient temperature (up to 5°С). If the ambient temperature is extremely high (about 45°C), then the air coming from the duct may also have a relatively high temperature (approximately 16°C), but, as a rule, the air conditioning temperature is 2-5°C lower than the temperature outside the car.

10. If there is insufficient air cooling, then the system probably needs to be recharged.

11. If the air remains warm and the system does not operate, check that the compressor drive clutch is working properly.

12. Having asked an assistant to turn on the air conditioning system, inspect the front side of the compressor. The clutch should click and the center section should begin to rotate. If this does not happen, stop the engine and disconnect the system low pressure circuit sensor (see illustration 13.22). Close the connector contacts with the connecting wire and turn on the air conditioning system again. If this triggers, the pressure in the system is too high or too low. Contact a proprietary or appropriately specialized station to diagnose the system.

13. If the clutch does not operate, inspect the appropriate fuse. Inspect the fuses located in the indoor unit.

14. Remove the compressor clutch relay for testing (A/C) from the panel located in the engine compartment (chapter 12). With the relay removed and the ignition on, make sure that voltage is supplied to the two contact terminals of the relay. When the ignition is turned on, power must be supplied to the contact terminals of the relay power circuit, as well as the control circuit.

15. Using an additional wire, connect the contacts of the relay power circuit located in the block with the contact of the wire leading to the compressor drive clutch (in order to determine which terminals need to be connected, check the color and location of the wires according to the electrical diagrams). When connecting the contacts, you should hear a click from the drive coupling. If the clutch does not click, disconnect its connector from the compressor and make sure that voltage is supplied to it from the battery. Make sure there is continuity in the compressor clutch grounding circuit connected to the black pin of the connector. If the clutch does not operate, and the power and grounding circuits of the circuit are in good working order, then the fault lies directly in the compressor clutch.

16. If, when the system is turned on, the compressor clutch does not engage, while the clutch, relay and electrical circuits are in good working order, and the system is fully charged with refrigerant, contact a company or other specialized station to diagnose the electronic PCM unit and examine the corresponding electronic circuits.

17. Conducting a more detailed inspection and more in-depth diagnostics are beyond the capabilities of a car mechanic.

Refrigerant charging

Caution: When recharging or replacing components, use R-134a grade refrigerant, oil, and seals. Seals and compressor oil used in conjunction with conventional R-12 refrigerant are incompatible with the described air conditioning systems.

18. Purchase the appropriate kit for charging the system with R-134a refrigerant from an auto store (see illustration). The kit consists of a 400 gram can of R-134a refrigerant, a threaded fitting, and a short hose that connects to the threaded fitting and the A/C service valve located on the low pressure circuit. Since one can of refrigerant may not be enough to fully charge the system, it is a good idea to purchase an additional can.

13.18. Refrigerant (Available for free sale in car dealerships) refills the low pressure circuit using a simple

Warning: It is prohibited to charge more than two cans of refrigerant into the system.

19. Connect the system charging kit according to the instructions included with it.

Warning: Do not connect the kit to a high pressure circuit. The fitting of the kit can only be connected to the low pressure circuit.

20. Unscrew the valve of the fitting included in the kit and screw the fitting onto the refrigerant can, first making sure that the O-ring or rubber gasket on the threaded part of the fitting is not displaced from its original location.

Warning: When working with cans containing high pressure refrigerant, wear safety glasses or a mask.

21. Remove the dust cap from the service valve connector located in the low pressure circuit of the air conditioning system and connect the quick connect hose included in the kit to the valve (see illustration).

13.21. Connect the kit to the low pressure marking located on the battery

22. Warm up the engine to normal operating temperature and turn on the air conditioning system. Do not allow the hose to get into the fan blades or other moving parts of the engine.

13.22. The low pressure switch for the air conditioning system is located on the battery. If the compressor drive clutch does not engage when priming the system, disconnect the connector and short-circuit the terminals (on the wiring harness) connecting wire

Note 1: Refrigerant charging is carried out with the compressor running. If the clutch is on its disengaging cycle, move the A/C switch to the maximum output position and leave the car doors open to keep the clutch on its engaging cycle.

Note 2: If the compressor clutch does not turn on when charging refrigerant, pull out the low pressure circuit breaker plug and short-circuit the connector pins with a straightened paperclip or shunt wire (see illustration).

23. Screw in the fitting valve to pierce the membrane of the refrigerant can with its pin, then unscrew the valve again to release the refrigerant. In this case, the hissing of the escaping gas should be heard. When refueling the system through the low pressure circuit, keep the can in an upright position, shaking it periodically. Refilling should be done at intervals necessary to stabilize the temperature in the system.

Note: If you wrap a towel soaked in hot water around the jar, which will prevent the jar from icing, the filling process will speed up.

24. Install a thermometer on the central vent of the dashboard and use it to monitor the temperature of the air supplied to the cabin. If the system is fully charged with refrigerant, the thermometer should display about 5°C. If the ambient temperature is extremely high (about 45°C), then the air coming from the deflector may also have a relatively high temperature (approximately 16°C), but, as a rule, air is supplied from the system to the cabin, which is colder than outside by about 2-5°C.

25. When the can is empty, close the fitting valve and disconnect the hose from the low pressure circuit service valve. Replace the dust cap.

26. Disconnect the hose from the can. Store the kit with the valve closed to prevent accidental puncture of the refrigerant canister membrane during the next refill.

Heating system

27. Moisture on the mat under the heater, as well as the smell of antifreeze spreading from the deflectors (or steam coming out of there) are signs of a leak in the heater heat exchanger. In this case you will have to remove it (see subsection 12) and install a new element (Most specialized workshops do not repair leaking heat exchangers).

28. The heating system may not work efficiently for the following reasons.

- A) The thermostat is stuck in the open position, which prevents the coolant that circulates in the heater from warming up sufficiently. Replace thermostat (see subsection 3).

- b) Insufficient passage of the heater hose, which limits the circulation of coolant. Touch both heater hoses entering the engine compartment bulkhead. They should be hot. If one of the hoses does not heat up, it means that the passage of the hose or the heater is limited, or the heater tap is closed. Disconnect the hoses and flush the heater by directing a reverse flow of water into it from the watering hose. If the heater is not clogged but is not circulating properly, remove the hoses and flush them with a stream of clean water.

- With) If the heater's permeability is reduced, and this problem is not solved by flushing, the heat exchanger should be replaced (see subsection 12).

Eliminating the characteristic unpleasant odor from the air conditioning system

29. The formation of an unpleasant odor in the air conditioning ducts is a consequence of the growth of fungus on the surface of the evaporator. Warm and humid environments are ideal for mold growth.

30. Access to the evaporator on most models is very difficult. Maintenance and repair stations have a lengthy and expensive mold removal procedure, during which the evaporator casing is opened and the mold is completely removed using powerful chemicals. You can remove mold from your air conditioning system yourself, but this will require special chemicals that are much more powerful than regular household detergents and deodorants.

31. Automotive stores have a wide selection of aerosol products for disinfecting automobile air conditioning systems, but it should be noted that the price and effectiveness of the product are directly related. The procedure should begin by running the air conditioning system for ten minutes in recirculation mode («RECIRC») at the highest fan speed. You should also set the air conditioning temperature to maximum to dry out the system and disconnect the clutch connector to prevent the compressor from shutting down during the procedure (see subsection 15).

32. Disinfectant usually comes in an aerosol with a long hose. Remove the lower instrument panel trim located on the passenger side, then remove the small service cover located on the HVAC unit housing (heater/air conditioner). Insert the tip into the hole and move it to the left, towards the evaporator coil, and spray according to the accompanying instructions (see illustration). Try to apply the product to the entire surface of the evaporator, directing the aerosol stream up, down and to the sides. The duration of spraying and the intervals between sprays should be in accordance with the instructions of the disinfectant manufacturer.

13.32 Spray antiseptic on the evaporator coil. Cover the mat in the spray area with plastic wrap or cloth mat

33. After cleaning the evaporator, the best prevention of mold is to periodically check the patency of the drain tube (see illustration 13.1).

Automatic heating/air conditioning system

34. On some of the vehicles described, an automatic climate control system is used as an option. This system has a separate control unit, which receives impulses from various sensors of heating and air conditioning systems. Like the engine control system, this system also has a self-diagnosis function, which allows you to determine the causes of possible problems. Repairing elements and restoring the functionality of the automatic climate control system is beyond the capabilities of a car mechanic. If problems occur, contact a proprietary or specialized station.