Warning: Before proceeding with this procedure, you should wait until the engine has completely cooled down.

Functionality check

1. A faulty coolant pump may cause the engine to overheat, resulting in serious engine damage. There are three methods for checking the functionality of the cooling system pump installed on a car. If during testing using one of the above methods it is determined that the pump is faulty, it should be replaced.

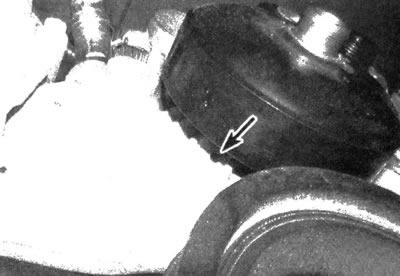

2. The pump impeller shaft has a seal that protects it from contamination by coolant. If the pump seal fails, coolant leaks out of the hole (see illustration) (If the hole is not located on top of the pump, use a mirror to inspect the back of this element). If liquid leaks from the hole, the impeller shaft bearing may fail. Replace the pump immediately.

7.2. The drain hole is usually located at the base of the coolant pump

3. The impeller shaft bearing may also wear out during normal use. Failure of the shaft bearing is characterized by the fact that the pump emits a characteristic squeal. If there is such a sound coming from the pump while the engine is running, a conclusion should be made that the shaft bearing has failed and the pump should be replaced immediately.

Note: Do not confuse the sound of a slipping drive belt with the characteristic sound of a worn or damaged pump bearing.

4. To determine the degree of wear of the shaft bearing, remove the drive belt (see chapter 1), grab the pump pulley with your hand and try to swing it in all possible directions. If the shaft moves in a horizontal or vertical direction, it means that the bearing has a maximum degree of wear. In this case, it is necessary to replace the cooling system pump.

5. It may happen that a failed pump will not leak or make a squealing sound. Sometimes the plates located on the back side of the impeller become covered with a coating of corrosion, and the pump fails. Such defects are revealed only during inspection of the removed pump.

Replacement

6. Disconnect the negative battery cable.

7. Drain the coolant (see chapter 1). Remove the intake air duct along with the resonator.

8. Remove the radiator shroud along with the fan/clutch (see subsection 5).

9. Remove the drive belt (see chapter 1).

10. Remove the coolant pump pulley (see illustration).

7.10. When unscrewing the bolts, it is necessary to fix the coolant pump pulley using a pin wrench (or a belt device that needs to be wrapped around the pulley)

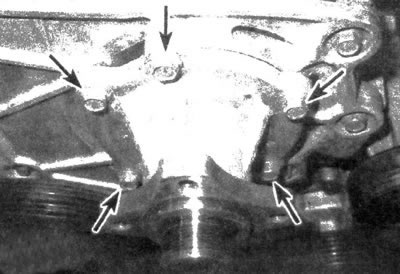

11. Unscrew the pump mounting bolts (see illustrations). It may be necessary to hit the pump connection with a soft hammer to break down the insulation on the pump connection. Inspect the plates located on the back of the impeller for corrosion deposits. If there are no plates or if corrosion deposits are found on them, the pump should be replaced.

7.11. Coolant pump mounting bolts

12. Remove insulating material from the mating surfaces of the pump and cylinder block. Wipe the mating surfaces with a cloth soaked in acetone.

13. Apply RTV sealant to both sides of the gasket and place it on the pump.

14. Install the pump, insert the mounting bolts and tighten them with your fingers. Do not allow the gasket to move. Tighten the bolts to the required torque.

15. Install the pulley and tighten the bolts to the required torque.

16. The rest of the installation procedure is performed in the reverse order of removal.

17. Fill the cooling system with an appropriate antifreeze solution (see chapter 1), start the engine and check the fluid level in the cooling system. Bleed the system as described in Chapter 1. Ensure that there is no fluid leakage through the pump and any hoses connected to it.