Warning: Dust generated when brake pads are worn away is a health hazard. Do not use compressed air to remove this dust and be careful not to inhale it. To clean brake elements, use only a special solvent. When servicing the brake system, it is advisable to wear a respirator.

Note: Detailed illustrations regarding the braking system are provided in Chapter 9.

1. In addition to inspection at prescribed intervals, inspect the brake system whenever you remove wheels or suspect a problem with the system.

2. Indicators of the presence of problems in the braking system are such signs as the car pulling to the side when braking, the presence of noise in the brakes when they are applied, an increase in the pedal stroke, a pulsation felt when pressing the pedal, and the presence of brake fluid drips on the inner end surface wheels

3. Loosen the wheel nuts.

4. Raise the car with a jack and install special supports.

5. Remove the wheels (see subsection «Lifting a car with a jack and towing» at the beginning of this manual or to the instructions in the vehicle owner's manual).

Disc brakes

6. Each caliper has two pads - internal and external. The brake pads are visible after the wheels are removed. The vehicles described here use front and rear disc brakes with a drum-type mechanical parking brake located inside each rear brake disc.

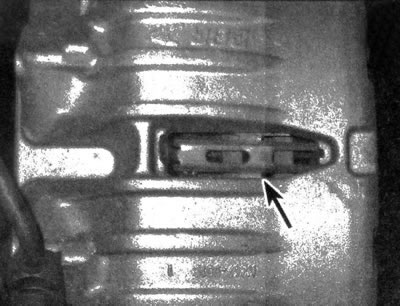

7. Through the hole in each caliper, inspect the brake pad linings (see illustrations). If the thickness of the linings is less than the value given in the specifications of this chapter, replace the pads.

19.7a. After removing the wheel, check the thickness of the inner brake pad lining through the inspection hole (shown on the front brake; The rear disc brake design is similar)

19.7b. It is easier to check the thickness of the outer brake pad lining at the edge of the caliper

Note: Do not include in your measurements the thickness of the metal base to which the trim is glued or riveted.

8. If it seems difficult to check the thickness of the linings using the method described above, if you are concerned about the condition of the brake pads, remove the calipers, then remove the pads from them for further thorough inspection (see chapter 9).

9. After removing the pads from the caliper, clean them with a special product and measure the thickness of the pads with a steel ruler or caliper (see illustration).

19.9. To accurately determine the thickness of the lining, remove the brake pad

10. Make sure that the thickness of the brake discs corresponds to the standard by measuring with a micrometer. If any disc is thinner than the specified minimum thickness, replace it (see chapter 9). Even if the disc thickness meets the standard, check its condition. Pay attention to the disc for chips, scratches, or areas that have been exposed to excessive heat. If the described defects are present, remove the disk and machine its surfaces (see chapter 9).

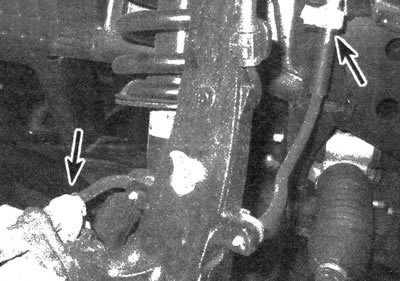

11. Before installing the wheels, make sure there is no leakage of brake fluid, as well as damage, critical wear, deformation, cracking, corrosion, kinks and twisting of hoses and pipes of the system, especially in the area of brake caliper hoses (see illustration). Check the connections and make sure there are no signs of leaks in the connectors. Make sure that hoses and pipes do not come into contact with sharp edges, moving parts or exhaust system components. If there are contacts as described, rearrange or properly lay out the hoses and tubes (see _ chapter 9).

11.19. No translation

Checking the functionality of the brake system vacuum booster

12. While in the driver's seat, check using the following method.

13. Press the brake pedal all the way and start the engine. At the same time, it should move down slightly.

14. Without turning off the engine, press the pedal several times. Its progress must remain constant.

15. Depress the brake pedal, turn off the engine, and continue to hold it down for approximately 30 seconds. The pedal position should not change when pressed.

16. Start the engine and leave it running for approximately one minute, then turn off the engine. Press the brake pedal all the way down several times. With each press, a decrease in stroke should be noted.

17. If the brakes do not work as described above, then the vacuum brake booster needs to be repaired or replaced. The procedure for removing the vacuum booster is described in Chapter 9.

Parking brake

18. The check is carried out when the vehicle is stopped on a slope and the parking brake is applied with the gearbox in neutral. You must remain in the driver's seat during this test. If the vehicle is not held by the parking brake, adjust (see _ chapter 9).