2. The tires that vehicles are equipped with at the factory have an indicator strip 12.7 mm wide (1/2"), which appears when the tread wears down to a critical depth of 1.6 mm (1/16"). The degree of tire wear can be assessed by using a simple and inexpensive device known as a tread depth gauge (see illustration).

5.2. To assess tire wear, use an inexpensive tread depth gauge, available at most auto parts stores

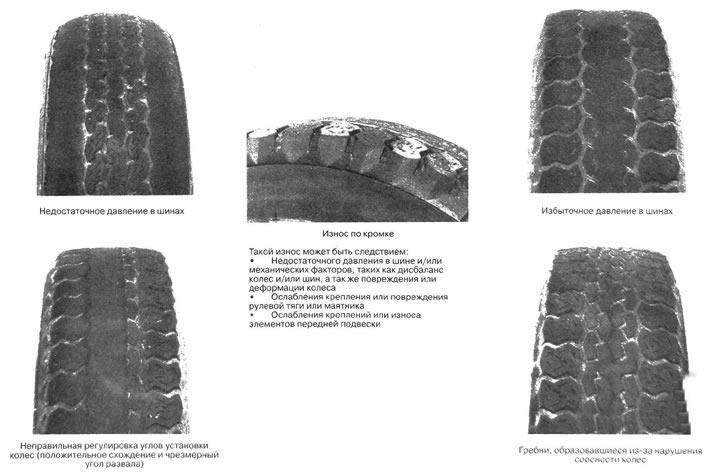

3. Look for signs of abnormal tread wear (see illustration). Wear of the tread along one of the edges, the presence of worn areas and uneven wear of tires installed on different sides of the vehicle indicate incorrect wheel alignment or imbalance of tires and/or wheels. If there are signs of abnormal wear, you should go to a service station or tire repair shop to have the problem corrected.

5.3. This diagram will help assess the condition of the tires, determine the probable cause and necessary repair measures

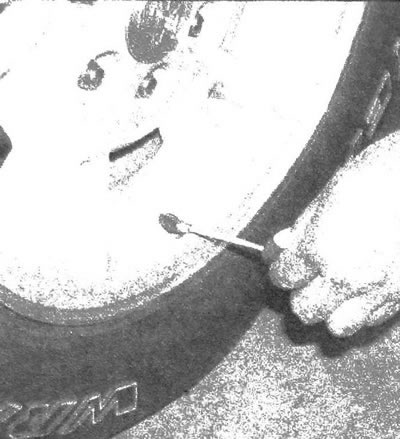

4. Make sure there are no cuts or punctures, and that there are no sharp objects stuck in the tread. Sometimes a tire punctured by a nail stuck in the tread can maintain pressure for some time and at the same time slowly deflate. If a tire installed on a vehicle is running low, make sure the valve spool is sealed (see illustration). Make sure that there are no sharp objects stuck in the tread, and also check the tightness of the vulcanization patches if punctures have previously been repaired by installing them. A puncture can be easily detected by applying a soapy water solution to the tire (see illustration). Blisters will form at the puncture site. In most cases, a punctured tire can be repaired in a workshop.

5.4a. When deflating a tire, first of all, make sure that the valve spool is sealed (You can purchase an inexpensive device for this purpose)

5.4b. If the spool is in good condition, jack up the car from the side of the flat tire. Rotate the wheel slowly while spraying the soap solution onto the tread. The puncture site is determined by the presence of small air bubbles

5. Carefully inspect the inside end surface of each tire for brake fluid leaks. If there are leaks, immediately check the condition of the brake system components.

6. Maintaining the required tire pressure extends tire life, increases mileage and improves vehicle handling. During an inspection, it is impossible to correctly assess whether tires are in compliance with the standard pressure, especially when it comes to radial tires. You must use a pressure gauge. Purchase this instrument and store it in the instrument panel drawer. Compressor pressure gauges for tire inflation often have a high measurement error.

7. Check the pressure only when the tires are cold, at least three hours after driving the car. In heated tires, the pressure is usually 0.3-0.5 atmospheres higher.

8. Unscrew the protective cap of the spool located on the wheel rim and connect the pressure gauge (see illustration). Measure the pressure and compare the results with the specifications shown in the table on the driver's door. Do not forget to install protective caps, the presence of which prevents dirt and moisture from penetrating into the spool valves. Check all four wheels and, if necessary, inflate the tires to the required pressure.

5.8. To extend the life of your tires, check your tire pressure weekly with a tire pressure gauge

9. Remember to maintain the required pressure in the spare tire (see user manual). It should be noted that the inflation pressure of a spare tire is significantly higher than the inflation pressure of a regular tire.