Note: Steering and suspension components should be inspected regularly. Symptoms such as uneven tire wear, increased fuel consumption, excessive vehicle sway when driving on uneven roads, or excessive body lean when cornering indicate faulty steering and/or suspension components. Descriptions of systems and illustrations are given in Chapter 10.

Checking shock absorbers

1. Place the vehicle on a horizontal surface, turn off the engine and apply the parking brake. Check tire pressure.

2. Check the performance of the shock absorbers by rocking the car around the corners one by one.

3. If the car does not stabilize after one or two vibrations, the shock absorbers may have reached their wear limit and require replacement.

4. Rock the car around each corner.

5. Raise the car using a jack and place it on special supports.

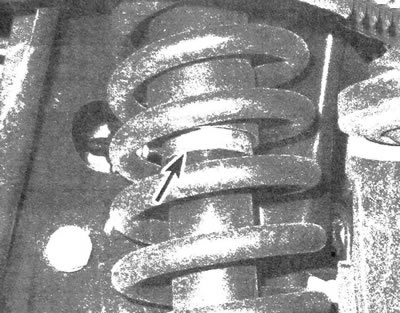

6. Inspect shock absorbers for signs of fluid leaks (see illustration). It is normal for a shock absorber to have a thin oily film. If there are traces of liquid, make sure that this is a result of a leak in the shock absorbers. In this case, the entire set should be replaced.

26.6. Check for leakage in the specified area of the shock absorber (front suspension strut shown)

7. Make sure the connection is secure and that the shock absorbers are not damaged. Inspect the top fastenings. If there is damage, the entire set of shock absorbers should be replaced (front and rear).

8. The replacement procedure is described in Chapter 10.

Checking the condition of steering and suspension elements

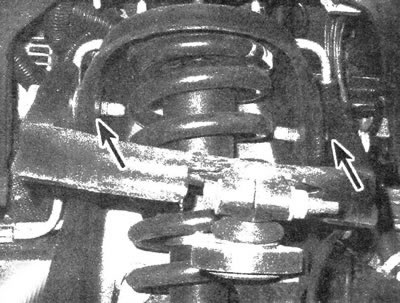

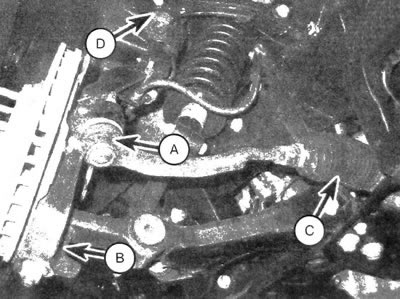

9. Inspect the suspension and steering components for damage or deformation. Make sure there are no leaks of operating fluids and lubricants, as well as the integrity of seals, boots and rubber bushings. Inspect the bushings that connect the suspension arms to the supporting frame elements (see illustrations).

26.9a. Inspect the attachment points of the upper...

26.9b....and lower control arm

26.9s. Inspect the tie rod ends (A), lower ball joints (IN), steering gear covers (WITH) and upper hinges (D)

10. Clean the lower surface of the hub knuckle. Ask an assistant to progressively move the wheel in a horizontal plane, grasping the lower edge. At this time, evaluate the movement in the support joint between the hub knuckle and the suspension arm. If there is play, replace the support.

11. Grab the front wheel at the 3 and 9 o'clock positions and try to rotate it by pushing in the front edge and pulling out the rear. Check for play in the steering if there is play in the intermediate lever of the steering gear and tie rod ends (see illustration).

26.11. By blocking the steering column of a raised vehicle. grab the front wheel and make forward and backward movements. If there is play, check that the steering mechanism is securely fastened and the tie rod ends are tightened

12. On vehicles with air suspension, it is necessary to inspect the air shock absorbers and pneumatic lines for damage to elements, cracks and depressurization.

13. Detailed descriptions and illustrations related to steering and suspension systems are provided in chapter 10.

Inspection of drive shaft covers (all-wheel drive models)

14. Rubber covers of the drive shaft serve to protect the CV joints from the penetration of sand, water and other foreign materials, thereby preventing the failure of the joints. It is recommended to wash the drive shaft covers with a soapy solution, since ingress of oil and other lubricants gradually destroys their material. The outer CV joints, which constantly move when the wheels turn, wear out faster than the inner joints and require regular inspection.

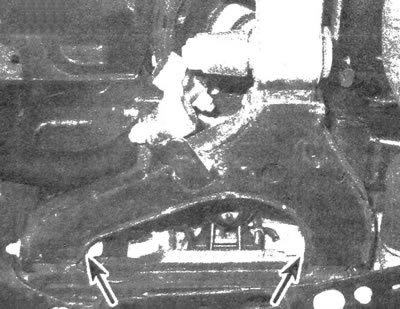

15. Inspect the covers for cracks and tears, and also make sure that they are securely fastened with clamps (see illustration). If cracks or signs of lubricant leakage are detected, the covers should be replaced as described in chapter 8.

26.15. On all-wheel drive vehicles, the internal and external drive shaft boot must be inspected for loose clamps, cracks and signs of lubricant leakage (inner cover shown)