1. The serpentine drive belt is located at the front of the cylinder block. Its normal condition and proper adjustment are one of the determining factors for the proper operation of the engine and attachments. Over time, the degree of wear increases, which is due to the high loads to which drive belts made of rubber are subjected. This makes periodic inspection necessary. The belt transmits rotation to elements such as the alternator, power steering pump, cooling system pump and air conditioning compressor.

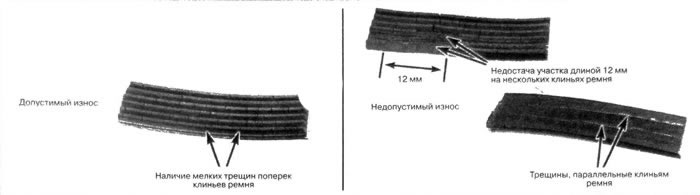

2. With the engine off, open the hood. Using a flashlight, feel the belt and determine if the rubber base is peeling from the cords on both sides. Make sure there are no excessively worn areas that have a characteristic matte appearance (see illustration). The belt should be inspected on both sides.

12.2. Inspect the serpentine belts (serpentine drive belts) - if they have the indicated defects, replace them

3. The depth of the grooves between the belt ribs located on the reverse side must be the same.

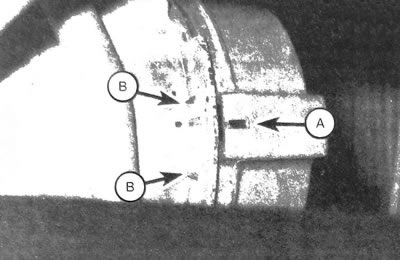

4. Belt tension is automatically maintained by a spring mechanism and cannot be adjusted. The alignment of the marks on the tension mechanism indicates the need to replace the belt (see illustration).

12.4. Drive belt tensioner indicator mark (A) must align with the mark located on the tension mechanism (IN)

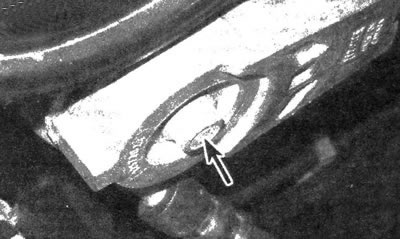

5. To replace the belt, you must first loosen it by turning the tensioner clockwise (see illustration).

12.5. Using a special tool, turn the tensioner clockwise and remove the belt (there may not be enough space to use a regular pry bar or ratchet wrench)

6. Remove the belt from the tensioner and attachment pulleys, then slowly release the tensioner pulley.

7. After comparing the length of the removed and new belt, put the new belt on the serpentine drive pulleys, while holding the tensioner. Release the tensioner.

12.7. There is a belt tension diagram on the radiator support

Note: The belt tensioning guide is located on the radiator support - pay attention to it (see illustration).

Replacing the tensioner

See _ illustration 12.8

8. When replacing a tensioner that is wedging or has a worn pulley/bearing, you must remove the belt and unscrew the fastening bolt (see illustration).

12.8. The bolt that secures the drive belt tensioner

9. Installation is carried out in the reverse order of removal.

Note: It is necessary that the tension mechanism indicator pin fits into the hole that is located on the tensioner support surface.