Front suspension

Front suspension (see illustration) is completely independent. Each wheel is connected to the frame via a steering knuckle, an upper and lower ball joint, and an upper and lower control arm. All described models use units consisting of a shock absorber and a spring (called shock absorber struts). Lateral vibrations of the vehicle when turning are reduced due to the presence of a stabilizer connected to both lower suspension arms and the frame.

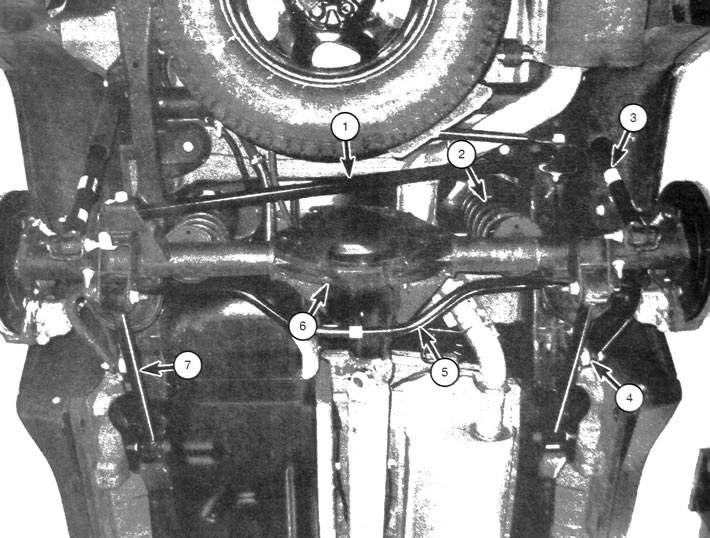

1.2. Rear suspension1. Transverse thrust; 2. Spring; 3. Shock absorber; 4. Anti-roll bar link;5. Anti-roll bar; 6. Rear axle; 7. Longitudinal thrust (lower; the top link is invisible from this angle)

Rear suspension

The rear suspension of the cars has a five-link design, coil springs, upper and lower control arms, a transverse link, two shock absorbers and an anti-roll bar (see illustration).

Steering

Steering components include a rack-and-pinion steering gear and two adjustable tie rods. A hydraulic booster is used as standard equipment. The design may include a steering damper, which is connected to a bracket located on the frame, as well as to a transmission rod.

Ground clearance system

As an option, the car can have an air-type rear suspension. Instead of conventional springs, this design provides for the presence of air cushions, the height of which is automatically adjusted depending on the load of the vehicle. The adjustment occurs when air is pumped by the compressor.

Precautionary measures

Often when servicing a steering or suspension system, you encounter connections that are very difficult to disconnect. Due to their location on the underside of the car, they are constantly exposed to moisture and road dirt, which leads to intense corrosion and jamming. To disconnect without damage, you should pre-treat such connections with a penetrating lubricant and wait for it to absorb. Use a wire brush to clean the exposed threads, which will make it easier to remove bolts and nuts and prevent damage to the threads. Occasionally, give a sharp blow with a hammer to dislodge the threads of a stuck joint, but do not use excessive force as the threads may be stripped. Sometimes heating the jammed connector and the surrounding area will facilitate separation, but this method is not recommended as it carries the risk of vehicle fire due to the use of an open flame. Long pry bars or lengths of pipe can be used to increase leverage, but do not use an extension when using a ratchet lever as this may damage the ratchet mechanism. Often turn a bolt or nut in the direction of tightening (clockwise) Helps loosen jammed connectors. Connectors that were unscrewed using emergency measures. must be replaced during subsequent assembly.

Most of the procedures described in this chapter require jacking up the car and performing operations from the underbody, so you should first prepare a pair of reliable supports on which the raised car will rest. When lifting a vehicle, it is advisable to use a hydraulic floor jack, which can also be used to support units during various procedures.

Warning: When performing procedures, do not allow the raised vehicle to rest solely on the jack. When unscrewing or removing connectors of suspension or steering elements, inspect them every time. if necessary, subsequent replacement with parts of the same dimensions and with the same technical characteristics or connectors of the original production. To ensure successful assembly, as well as to ensure reliable fastening of elements, the specifications regarding the tightening torques of the connectors must be adhered to. Do not heat or straighten deformed suspension and steering components. Such parts and assemblies must be replaced with new spare parts.