Removal

1. Disconnect the negative battery cable.

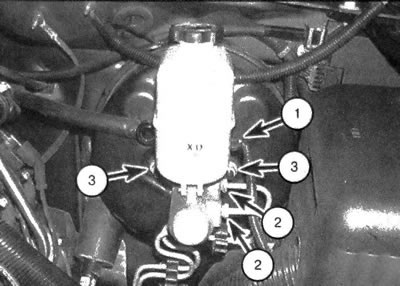

2. Disconnect the plug of the emergency fluid level indicator in the tank (see illustration).

6.2. Brake Master Cylinder Parts A - Connector for the liquid level sensor in the tank; B - Connections of brake hydraulic system lines; C - Fastening nuts

3. Pump out as much brake fluid as possible from the master cylinder reservoir, using, for example, a cooking syringe.

Note: After this use, it is prohibited to use the culinary syringe for cooking.

4. Place an absorbent rag under the connectors and prepare suitable plugs or plastic bags to isolate the exposed brake lines after disconnection.

Caution: Brake fluid can damage your vehicle's paintwork. Cover painted surfaces of the vehicle to prevent brake fluid from entering. Be careful not to spill any liquid during this procedure. Loosen the fittings that connect the brake lines to the master cylinder. To prevent the ribs of the connecting nuts from rounding, when unscrewing, use a spanner wrench that fits around the hexagon of the fitting.

5. Pull the brake lines away from the master cylinder and plug the holes to prevent clogging of the system,

6. Unscrew the nuts securing the master cylinder to the vacuum brake booster (see illustration).

Pull the master cylinder off the studs and remove it from the engine compartment. Do not allow brake fluid to spill.

Installation

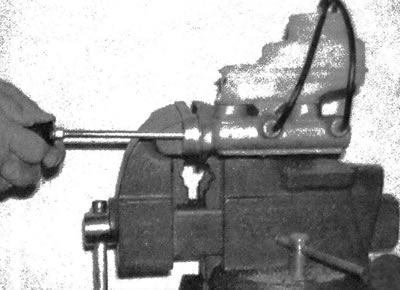

7. Before installation, it is necessary to bleed the new master cylinder. Secure it in a vice by clamping the flange.

8. Connect two bleeder tubes to the master cylinder outlet fittings (see illustration).

6.8. The most preferable method is to pre-bleed the master cylinder, when air is removed from it into the reservoir through two tubes

9. Fill the reservoir with the appropriate type of brake fluid (see chapter 1).

10. Slowly press the piston into the master cylinder to force air from the chambers into the reservoir. You can use a large Phillips screwdriver to move the piston. Since the tubes are immersed in the liquid in the reservoir, no air enters the cylinder when the piston is released.

11. Continue pumping until there are no air bubbles in the liquid.

12. Disconnect the bleeding tubes (one by one) and plug the cylinder fittings to prevent fluid from escaping and air from entering. Install the reservoir cap.

13. Install the master cylinder onto the brake booster studs and tighten the nuts with your fingers. Don't forget to install a new gasket.

14. Connect the threaded couplings of the brake hydraulic lines to the master cylinder. Since the cylinder nuts are not yet fully tightened, there should be no difficulty in guiding the union nut along the fitting threads. Do not allow the threads to break when tightening the nut.

15. Completely tighten the master cylinder nuts and hydraulic connectors. The nuts must be tightened to the required torque.

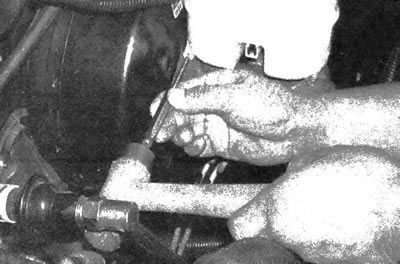

16. Fill the reservoir, then bleed the master cylinder and brake system circuits, as described in subsection 8. To bleed the installed master cylinder, you must have an assistant depress and lock the brake pedal in this position. Loosen the connection nut. to release liquid containing air (see illustration). Tighten the nut, then have an assistant return the pedal to its original position. Bleed through two fittings until then. until there are no air bubbles in the liquid. Before you begin normal operation of the vehicle, make sure that its braking system is working properly.

6.16. It is necessary to involve an assistant who will depress and lock the brake pedal in this position. Loosen the union nut to release the fluid containing air. Pump through two fittings until there are no air bubbles in the liquid

Warning: if the brake pedal has not acquired elasticity after bleeding, as well as if there is any doubt about the serviceability of the brake system, DO NOT drive the vehicle. It should be towed to a company station for diagnostics using special equipment.

Replacing the reservoir sealing ring

Note: If necessary, the reservoir can be replaced separately from the master cylinder body. To eliminate a leak that has occurred between the reservoir and the cylinder, you can replace the sealing ring located there.

17. Pump out as much brake fluid as possible from the master cylinder reservoir, using, for example, a cooking syringe.

Note: After this use, it is prohibited to use the culinary syringe for cooking.

18. Place a cloth under the master cylinder to absorb any liquid that may spill when the reservoir is disconnected.

Caution: Brake fluid will corrode paintwork. Cover adjacent body parts and do not allow any fluid to spill during this procedure.

19. Using a hammer and a small chisel, knock out the roller pins that secure the reservoir to the master cylinder (see illustration).

6.19. Drive out the roller pins that secure the reservoir to the master cylinder

20. Pull the reservoir off the master cylinder body.

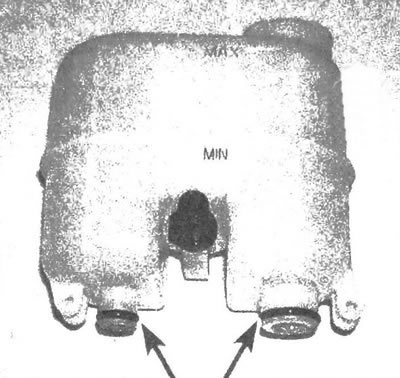

21. If you are only replacing the o-rings, pry and remove the old seals, then install new o-rings in their place (see illustration).

6.21. If a brake fluid leak is detected, the reservoir O-rings must be replaced

22. Lubricate the O-rings with clean brake fluid, then press the reservoir back into position on the master cylinder and secure it with new roller pins.

23. Fill the reservoir with the appropriate type of brake fluid (see chapter 1) and make sure there are no leaks.

24. Bleed the master cylinder (see illustration 6.16).