3.4a. Cut off the strip of fastening the protective cover on the shaft, then shift the protective cover to the center of the axle shaft |

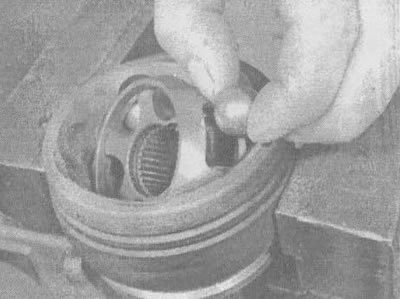

3.4b. Remove the thrust ring, move the hinge and remove the old protective cover |

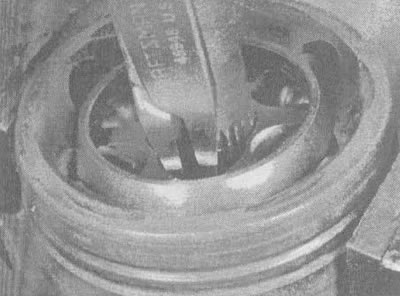

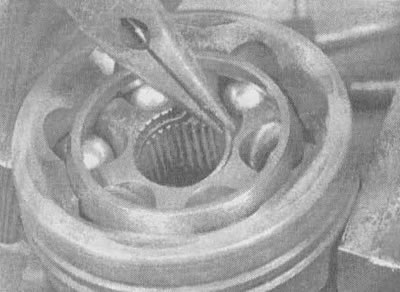

3.4c. Press down on the outer raceway so that the balls can be removed; if tilting is difficult, tap the cage and inner raceway gently with a punch or hammer |

3.4g Remove the balls from the cage one at a time using a blunt screwdriver or piece of wood |

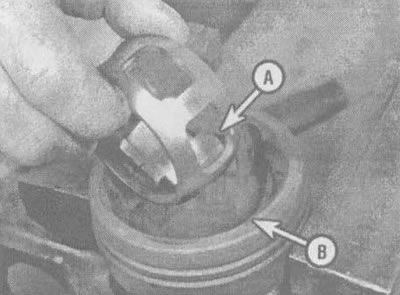

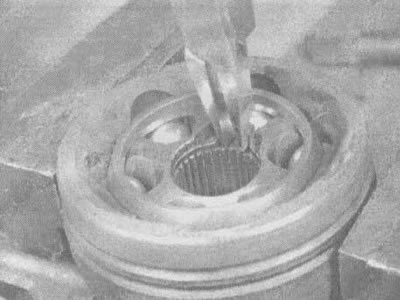

3.4d. Tilt the inner raceway and cage 90°, then line up the holes in the cage (A) with casing sections (B) and screw the inner raceway up and down from the outer raceway |

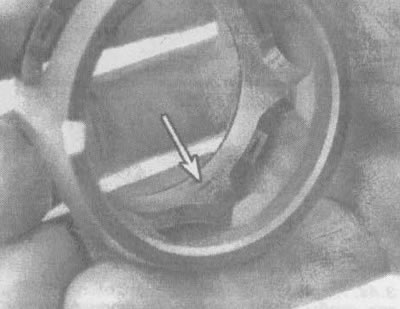

3.4e. Align sections of the inner raceway with the raceway of the cage and screw the inner raceway out of the cage |

3.4g. After cleaning the parts with solvent, check the edges and grooves of the inner track for corrosion and signs of scratches, nicks and gouges |

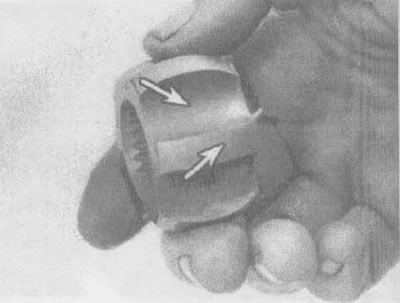

3.4z. Check the separator for cracks, corrosion, gouges, scuffs and scratches (shiny spots are normal and do not adversely affect the operation of the hinge) |

3.4i. With the raceway and cage at a 90°angle, lower the assembly into the casing |

3.4k. Turn the hinge by gently tapping with a hammer and punch, then... |

3.4l.... put balls one at a time into the separator windows until you have installed all |

3.4m. Using pliers, lower the retaining ring into the groove, then... |

3.4n....set its ring into the groove using special thrust ring pliers |

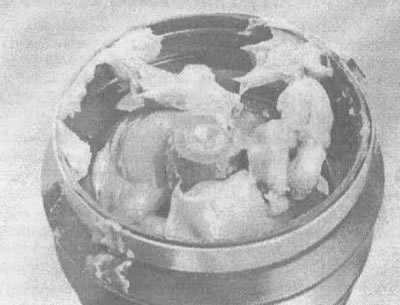

3.4o. Put grease through the inner spline hole into the constant velocity joint, then... |

3.4p.... insert a wooden rod (slightly larger than the diameter of the shaft) through the spline and push it in - this will force the grease into the hinge. Repeat this operation until the entire bearing is completely surrounded by grease |

3.4r. Put a protective cover on the axle shaft and put grease inside the protective cover of the axle shaft until... |

3.4s....until the lubricant level reaches the end of the axle shaft |

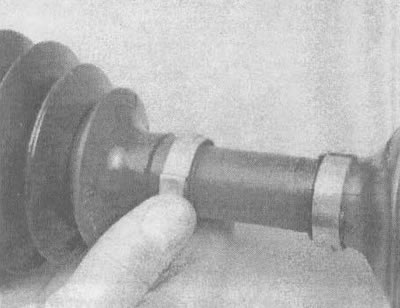

3.4t. Install the constant velocity joint on the axle shaft, aligning the splines; then, using a soft-faced hammer, push the hinge onto the axle shaft until the thrust ring is seated in the groove |

3.4u. Insert the inner end of the protective boot into the groove and put on the fixing collar, then do the same on the other end of the protective boot; tighten the clamps of the protective cover using a special tool (see illustration 3.3y)