General description

1. This system is designed to capture and accumulate fuel vapors evaporating from the gas tank, throttle body and intake manifold.

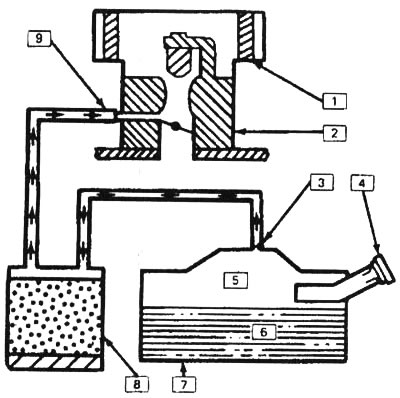

2. Gasoline vapor control system (EECS) consists of a filter tank filled with activated carbon and lines connecting this tank to the fuel tank and manifold, valve and vacuum tubes (see illustration).

8.2. Gasoline vapor control system installed on a 3.1 liter engine: 1 - air jet, 2 - TV block!, 3 - jet, 4 - pressure relief / vacuum cover, 5 - fuel vapors, 6 - fuel, 7 - fuel tank, 8 - tank, 9 - valve

3. Fuel vapors are transferred from the fuel tank, throttle body and intake manifold to the reservoir where they accumulate while the engine is not running. When the engine starts, fuel vapor is carried away from the reservoir by the air stream and burns along with the fuel.

Examination

4. If the engine idles poorly, stalls and has poor throttle response, a faulty valve, a damaged reservoir, and cracked or improperly connected hoses may be the cause.

5. Leaking or smelling gasoline can be caused by: leaks in the fuel lines or TBI unit, damaged reservoir, defective drain valve, damaged valve, disconnection, improper connection, excessive kinking, worn or damaged ventilation hoses or gasoline vapor control system or improper installation of the air filter or its gasket.

6. Check all hoses attached to the tank for kinks, leaks and breaks along their entire length. If necessary, repair the observed damage or replace the defective elements.

7. Check up a condition of a tank. If it cracks or is otherwise damaged, replace the tank.

8. Check for leaks at the bottom of the tank. If there is a fuel leak, replace the tank and check the technical condition of the hoses and the correctness of their laying.

9. Attach a short piece of hose to the lower valve port and try to blow it out. Very little or no air should pass into the reservoir (the ingress of a small amount of air is due to the fact that the tank has a constantly open vent).

10. Using a manual vacuum pump, create a vacuum in the area between the control valve tube and its diaphragm.

11. If the vacuum hold time of the diaphragm is less than 20 seconds, this means that it passes air and the tank should be replaced with a new one.

12. If the diaphragm holds vacuum well, try again to purge the hose while there is still vacuum in the system. This time the airflow should increase noticeably. If this does not happen, replace the tank.

Replacing elements

13. Disconnect all vacuum lines from the tank (see illustration), after applying well-defined marks on them.

8.13. To remove the tank, mark and disconnect the vacuum sampling tubes from it, then unscrew the tank clamp bolt and remove the tank

14. Loosen the clamp bolt and remove the tank.

15. Installation is carried out in the reverse order.