Two types of computers are used. Vehicles with 3.1L engine equipped with PROM ECM (programmable read only memory - PROM) and the CALPAK block. Vehicles with a 3.8L engine are equipped with a PCM with a MEM-CAL unit.

Note. The CALPAK block on engines with a displacement of 3.1 liters is not replaced. If the CALPAK fails, the entire ECM must be replaced.

The ECM/PCM controls the following parameters and processes:

- fuel consumption

- Ignition distribution (setting the lead angle)

- ignition control

- Exhaust Gas Recirculation

- The work of the air intake

- motor fan

- Air consumption at idle (IAC)

- torque converter

- Air conditioning control system

The work of the CCC system resembles the work of the central nervous system in the human body. Sensors (nerve endings) constantly send information to the ECM / PCM (brain), which processes the data and, if necessary, sends commands to change the operating parameters of the engine (body).

Let us give an example of the operation of one of the parts of the system. An oxygen sensor located in the exhaust manifold monitors the oxygen content in the exhaust gases. If the oxygen content in the exhaust gases is abnormal, an electrical signal is sent to the ECM/PCM. The ECM/PCM receives this information, processes it and sends a command to the fuel injection system to change the fuel/air ratio. This is done in a fraction of a second and is done continuously while the engine is running. The end result is a consistent fuel/air ratio, regardless of external conditions.

Perhaps some will find that a system equipped with an on-board computer and electrical sensors is difficult to test. This is not at all necessary. The CCC system includes a built-in diagnostic mode that indicates the presence of a malfunction by lighting a lamp "SERVICE ENGINE SOON" ("Have the engine serviced immediately") on the instrument panel. If this lamp comes on during normal engine operation, this means that a malfunction has been detected in the circuit of one of the information sensors or in the ECM / PCM itself. And more importantly, a fault code is stored in the ECM / PCM memory.

To retrieve this information from the ECM/PCM memory, a short jumper must be used to connect to "weight" diagnostic terminals. This terminal is part of the ALDL center connector (see illustration). ALDL is located under the dashboard and to the left of the center console. To use ALDL, remove the plastic cover (if it is installed), by pulling it towards you. Having opened the connector in this way, insert one end of the jumper into the diagnostic terminal, and press the other end to "mass".

2.6a. Central connector (ALDL) (shown by arrow) located under the dashboard next to the fuse box |

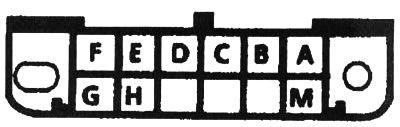

2.6b. Description of the terminals on the ALDL central connector: A - "weight", B - diagnostic terminal, C - AIR (if used), D - lamp "SERVICE ENGINE SOON" ("Perform engine maintenance immediately"), E - serial data (do not use - special device required), F-TCS (if used), G - fuel pump (if used), M - serial data (if used) |

When the diagnostic terminal is connected to "weight", the ignition is on and the engine is stopped, the system will enter diagnostic mode.

Attention! Do not start or rotate the engine crankshaft with the "weight" diagnostic terminal. In this mode, the ECM/PCM will display code 12 by flashing the lamp "SERVICE ENGINE SOON", indicating that the system is running. Code 12 corresponds to one flash followed by two flashes in a row after a short pause. This code will flash three times. If no other codes are stored in memory, code 12 will continue to be displayed until the diagnostic terminal is connected to "weight".

After code 12 flashes three times, the ECM/PCM will display any of the stored DTCs. Each such code will illuminate three times, then code 12 will illuminate again, indicating that the display of the stored DTC has completed.

When the ECM/PCM sets a DTC, the lamp will turn on "SERVICE ENGINE SOON", and the fault code is stored in memory. If the malfunction is temporary, then when it disappears after 10 seconds, the lamp will go out. However, the DTC will be stored in the ECM/PCM memory until the battery power to the ECM/PCM is turned off. Disconnecting the battery for 10 seconds will erase all stored trouble codes. Fault codes should always be erased after repair work is completed.

Attention. To prevent damage to the ECM/PCM, when power is applied to or removed from the ECM/PCM, the ignition key must be in the "OFF".

The above is a list of typical fault codes that may be encountered when checking a computer command control system. Simplified troubleshooting operations are also included. If these steps do not solve the problem, contact an auto repair shop.

| Error code | Circuit or system | Possible reason |

| Code 12 (1 flash, pause, 2 flashes) | Pulses are not sent from the distributor to the ECM / PCM | This code will be displayed whenever the diagnostic terminal is connected to "weight" with the ignition on and the engine off. If additional trouble codes are stored in the ECM/PCM memory, they will appear after this code repeats three times. If this code appears with the engine running, it means that the pulses from the distributor do not reach the ECM / PCM |

| Code 13 (1 flash, pause, 3 flashes) | oxygen sensor circuit | The throttle position sensor may be stuck or misadjusted. Check the wires and connectors associated with the oxygen sensor. Replace oxygen sensor |

| Code 14 (1 flash, pause, 4 flashes) | coolant sensor (heat) | If malfunctions appear in the cooling system, they must be repaired immediately. Check all wires and connectors associated with the coolant temperature sensor. Replace coolant temperature sensor * |

| Code 15 (1 flash, pause, 5 flashes) | coolant sensor (low temperature) | See above, then check all electrical connections to the ECM |

| Code 16 (only for 3.8L engine) (1 flash, pause, 6 flashes) | System voltage (high or low) | System voltage detected above 17V or below 9V |

| Code 18 (only for 3.8L engine) (1 flash, pause, 8 flashes) | Inconsistent position of the camshaft / crankshaft | Temporary malfunction associated with the signal from the camshaft / crankshaft or fuel supply signal |

| Code 21 (2 flashes, pause, 1 flash) | TPS Throttle Position Sensor (high voltage) | Possible stuck or misadjusted TPS (throttle position sensor). Check wires and connectors between TPS and ECM/PCM. Adjust or replace TPS sensor (see chapter 4) * |

| Code 22 (2 flashes, pause, 2 flashes) | TPS Throttle Position Sensor (low voltage) | Check TPS adjustment (chapter 4). Check the ECM/PCM connector. Replace TPS (chapter 4) * |

| Code 24 (2 flashes, pause, 4 flashes) | Vehicle speed sensor | An error in this loop should only be displayed when the vehicle is moving. Ignore code 24 if the drive wheels are not turning. Check connections at ECM. Check TPS settings |

| Code 26 (only for 3.8L engine) (2 flashes, pause, 6 flashes) | QDM error "A" | The PCM registers an incorrect voltage level in the circuit connected to the QDM (quadruple driving unit) "A" |

| Code 32 (only for 3.1L engine) (3 flashes, pause, 2 flashes) | Exhaust gas recirculation system (EGR) | Vacuum switch shorts on startup, switch does not close circuit after command from ECM to EGR for a specified period of time, or EGR solenoid valve circuit open for a specified period of time. Replace EGR valve * |

| Code 33 (only for 3.1L engine) (3 flashes, pause, 3 flashes) | MAP sensor | Check the vacuum hoses coming from the MAP sensor. Check the electrical connections at the ECM. Replace MAP sensor * |

| Code 34 (only for 3.1L engine) (3 flashes, pause, 4 flashes) | Vacuum sensor or MAP sensor | Code 34 will be set when the signal voltage from the MAP sensor is too low. The ECM will replace this signal with a fixed MAP value and will use the TPS for fuel control. Replace MAP sensor * |

| Code 34 (only for 3.8L engine) (3 flashes, pause, 4 flashes) | MAF sensor | Code 34 will be set when there is no signal voltage from the MAF sensor for a period greater than 4 seconds |

| Code 41 (only for 3.8L engine) (4 flashes, pause, 1 flash) | Camshaft sensor circuit | Code 41 will be set when there is no signal voltage from the camshaft sensor for a period greater than 5 seconds |

| Code 42 (4 flashes, pause, 2 flashes) | Electronic ignition distribution (EST) | EI distribution shunt circuit or EST circuit shorted or open (EST). The cause of this code may be a faulty HEI block |

| Code 43 (4 flashes, pause, 3 flashes) | Electronic ignition control (ESC) | The ESC delay signal has been active for too long or the system has not passed the ESC block functional test |

| Code 44 (4 flashes, pause, 4 flashes) | Oxygen sensor indicates lean exhaust | Check ECM electrical connections, especially terminals "15" And "8". Check TBI base gasket. vacuum hoses and intake manifold gasket for depressurization. Replace oxygen sensor * |

| Code 45 (4 flashes, pause, 5 flashes) | Oxygen sensor indicates enriched exhaust | It could be an injector malfunction or leak, high fuel pressure, or malfunctioning TPS and MAF sensors. Also, check to see if gasoline has entered the carbon vapor filter and its parts. Replace oxygen sensor * |

| Code 51 (5 flashes, pause, 1 flash) | PROM (engine 3.1 l) or MEM-CAL (engine 3.8 l) | Make sure the PROM or MEM-CAL is properly installed in the ECM. Replace PROM or MEM-CAL * |

| Code 52 (only for 3.1L engine) (5 flashes, pause, 2 flashes) | CALPAK | Make sure the ECM is installed correctly. Replace ECM * |

| Code 54 (only for 3.1L engine) (5 flashes, pause, 4 flashes) | Fuel pump | Low voltage fuel pump. Set when fuel pump voltage is less than 2V and when reference pulses are received |

| Code 55 (5 flashes, pause, 5 flashes) | ECM/PCM | Make sure the ECM connections are tight "weight". If so, replace the ECM/PCM * |

| Code 56 (only for 3.8L engine) (5 flashes, pause, 6 flashes) | QDM error "IN" | The PCM registers an incorrect voltage level in the circuit connected to the QDM (quadruple driving unit) "IN" |

* Replacing a system element may not always fix the problem. In this regard, before buying spare parts, consult with a specialist.

Note. There are several codes on 3.8L engines that are not displayed by the lamp "SERVICE ENGINE SOON" on the instrument panel. A special device is required to read these codes \ (GM Tech 1 Scanner).