General description

1. The coolant temperature sensor is a thermistor (resistor that changes resistance value with temperature). Changing the resistance values directly affects the magnitude of the signal voltage from the sensor. When the temperature decreases, the resistance increases. As the temperature increases, the resistance decreases. A failure in the sensor circuit will set codes 14 or 15. These codes indicate a malfunction in the coolant temperature control circuit and in most cases the solution to the problem is either to fix the defect in the wire or replace the sensor.

Examination

2. To check the sensor, determine the value of its resistance when it is completely cold (for temperatures of 10-30°C, the resistance varies from 5600 to 2400 Ohm). Then start the engine and warm it up to operating temperature. The resistance should be lower (for temperatures of 85-95°C, the resistance varies from 300 to 200 Ohm).

Note. The position of the coolant temperature sensor makes it difficult to install electrical probes on its terminals. If necessary, remove the sensor and test in a hot water tank to simulate appropriate conditions.

Replacement

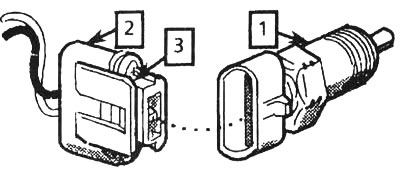

3. To replace the sensor, remove the fixing plate, disconnect the electrical connector (see illustration) and carefully unscrew the sensor.

4.3a. To remove the engine coolant temperature sensor (1) remove the retaining plate with a small screwdriver (3), disconnect the electrical connector (2) and carefully unscrew the sensor using a socket wrench |

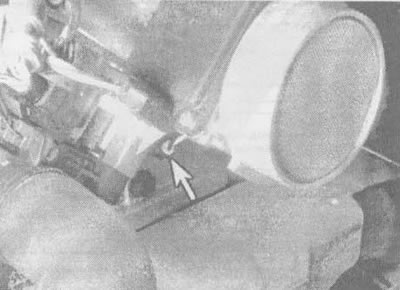

4.3b. The coolant temperature sensor on the 3.1L engine is located in the intake manifold near the TBI block |

4.Sound The coolant temperature sensor on the 3.8L engine is located in the intake manifold under the throttle body

Attention! Handle the sensor with care. Its failure will affect the operation of the entire fuel injection system.

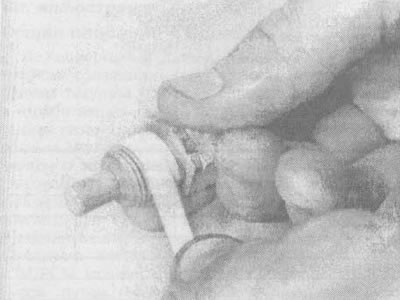

4. Before installing a new sensor, wrap the threads with Teflon sealing tape to prevent leakage and corrosion of the threads (see illustration).

4.4. Before installing a new sensor, wrap the threads with Teflon tape to prevent leaks

5. Installation is carried out in reverse order.