2. Remove the flywheel (see section 27).

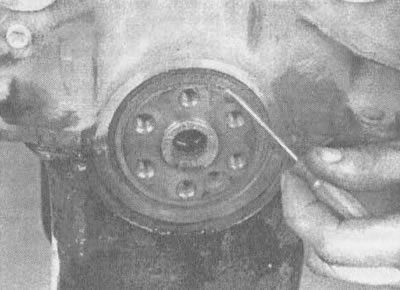

3. Remove the old oil seal with a screwdriver or special tool (see illustration). Be careful not to scratch or damage the surface of the crankshaft with the tool.

25.3. Carefully remove the old oil seal with a screwdriver or special tool (do not scratch the oil seal hole or the surface of the crankshaft)

4. Clean the hole in the block and the seal contact surface on the crankshaft. Check for nicks, scratches, and gouges in the bore or surface of the crankshaft. Even slight unevenness on the surface of the crankshaft can damage the lip of the oil seal and lead to oil leakage. If you notice slight damage, clean it with fine-grained sandpaper. If the damage is too great, you will have to regrind or replace the crankshaft.

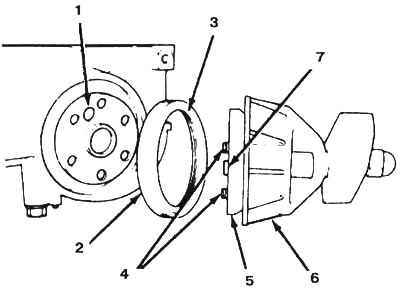

5. To install a new oil seal, it is recommended to use a special tool (see illustration). Lubricate the lip of the new oil seal with grease or clean engine oil, then slide the oil seal onto the mandrel until the bottom of the lip of the oil seal sits flat on the yoke (bead) fixtures.

25.5. Special tool J-34686 from General Motors, recommended for installing the oil seal: 1 - adjusting hole, 2 - gland lip, 3 - gland, 4 - mounting screws, 5 - mandrel, 6 - cage, 7 - dowel pin

Note. If there is no special tool, carefully slide the oil seal onto the crankshaft and tap with a hammer and punch until it sits exactly in place.

6. Align the dowel pin with its hole in the crankshaft and attach the tool to the crankshaft by hand-tightening the bolts.

7. Rotate the tool by hand until the bead settles on the sheath, releasing the seal.

8. Remaining operations are carried out in reverse order.