2. Lay out pistons with connecting rods and piston ring sets so that the set of rings corresponds to the same piston and cylinder both when measuring gaps in the lock and when assembling the engine.

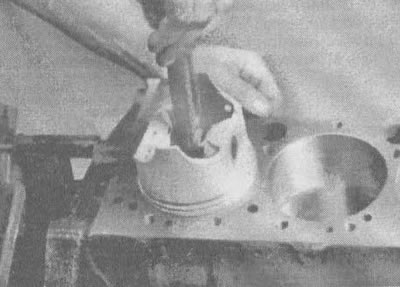

3. Insert the top (first) ring into the first cylinder and push it into the cylinder with the top surface of the piston (see illustration). The ring should be at the bottom of the cylinder at the lower end of the ring travel.

22.3. When checking the clearance in the piston ring lock, the ring must be inserted into the cylinder (it can be pushed there with a piston, as shown in the illustration)

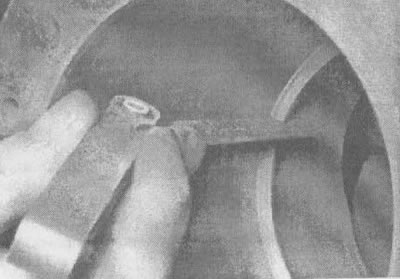

4. To measure the gap in the lock of the ring, insert the probes between the ends of the ring until you pick up a probe equal to the width of the gap (see illustration). The feeler gauge should slide between the ends of the ring with slight resistance. Compare the measurement result with the figures given in section "Technical data". If the gap is less than or greater than the required value, then before adjusting the gap, check again whether the ring you have chosen.

22.4. After inserting the ring into the cylinder, measure the gap between the ends of the ring with a feeler gauge

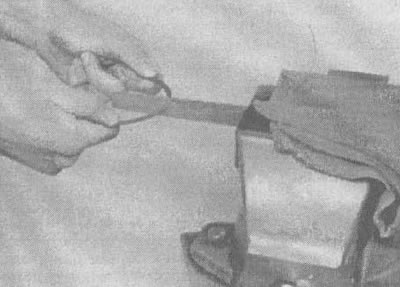

5. If the gap is too small, it must be increased, otherwise the ends of the ring may close together during engine operation, which can lead to serious damage to it. The gap between the ends can be increased by carefully grinding off the ends of the ring with a fine-grained file. Clamp the file in a soft-jawed vise, put the ring on the file so that its ends are in contact with the surfaces of the file and, moving the file slowly, remove the material from the ends. When performing this operation, grind the rings only by moving towards the inside of the ring (see illustration).

22.5. If the gap between the ends is too small, clamp the file in a vise and grind off the ends of the ring (sew only from outside to inside) for a slight increase in clearance

6. Excessive clearance becomes critical if it exceeds 0.040 inches. Check again that you have chosen the correct rings.

7. Repeat the procedure for each ring to be installed in the first cylinder and for each ring in the remaining cylinders. Agreed kits "piston-rings" for each cylinder must not be violated.

8. After checking and adjusting the gaps of the lock, the rings can be installed on the pistons.

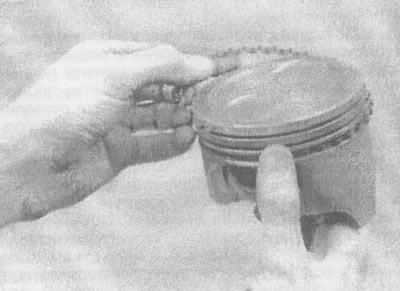

9. The oil scraper ring is installed first (the bottom ring on the piston). It consists of three separate parts. Insert the ring expander into the groove (see illustration). If an anti-rotation insert is used, make sure it fits into the drilled hole in the ring groove. Then install the lower part of the ring. When installing the ring parts, do not use a piston ring installer, as this may break them. Instead, insert one end into the groove between the expander and the wall, hold it firmly in place, and slide your finger around the piston to push the ring into the groove (see illustration). Then insert the top in the same way.

22.9a. Installing the expander in the oil scraper ring groove |

22.9b. Do not use piston ring pliers when installing the oil ring side guides |

10. After installing the ring parts, check that both the upper and lower parts of the ring can turn by sliding along the groove.

11. The second ring is installed next (average). A mark is usually stamped on it, which should be directed towards the top of the piston.

Note. Always follow the instructions printed on the ring packaging - different manufacturers may have different requirements. Do not confuse the top and middle rings as they have different cross sections.

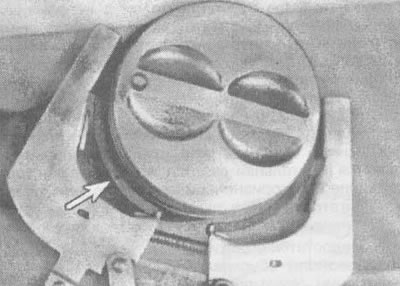

12. Use a piston ring installer and make sure the mark is towards the top of the piston, then install the ring in the middle groove on the piston (see illustration). Do not stretch the ring more than necessary to fit it on the piston.

22.12. Installation of compression rings with a ring expander. Label (shown by arrow) must be directed upward

13. Install the first ring in the same way (upper). Make sure the label is pointing up. Be careful not to confuse the first and second rings.

14. Repeat the procedure for the remaining pistons and rings.