Note. Before removing the pistons and connecting rods, remove the cylinder heads, oil pan and oil pump following the appropriate sections in part 2.1 of chapter 2.

1. Use your finger to determine if a protrusion has formed at the upper limit of the ring travel (approximately 1/4 inch below the top of each cylinder). If such protrusions are present due to carbon deposits or cylinder wear, they must be removed using a special tool (see illustration). Follow the manufacturer's instructions that came with the tool. Attempting to remove pistons and connecting rods without removing the lugs may damage the pistons.

13.1. Removing the tab at the top of each cylinder requires a special tab removal tool; do this before removing the pistons

2. After removing the protrusions on the cylinder, turn the engine over so that the crankshaft is on top.

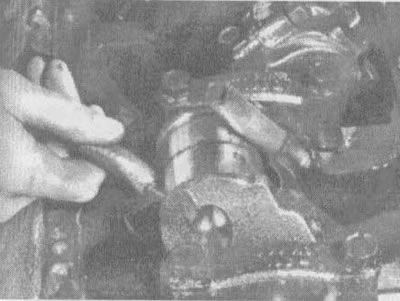

3. Before removal of rods measure an axial backlash by means of probes. Insert various feeler gauges between the first connecting rod and the crankshaft crank until there is no play (see illustration). The axial clearance is equal to the thickness of the last stylus. If the axial clearance exceeds the allowable limit, the connecting rods need to be replaced. If new connecting rods were installed (or new crankshaft), end clearance may be less than the minimum specified in this chapter. In this case, the connecting rods must be processed to restore the clearance - if necessary, consult an auto repair shop. Repeat this procedure for the rest of the connecting rods.

13.3. Check the axial clearance of the connecting rod as shown using feeler gauges

4. Check up presence of tags on covers of rods. If the marks are hard to see, use a center punch (see illustration) put the appropriate identification numbers on each connecting rod and cap (1, 2, 3, etc. depending on the cylinder they belong to).

13.4. Mark the connecting rod bearing caps starting at the front of the engine and moving towards the rear (one label for the front cover, two for the second cover, and so on)

5. Loosen each connecting rod cap nuts 1/2 turn one at a time until they can be turned by hand. Remove the cover and bearing shell of the first connecting rod. Do not drop the bearing shell from the cover.

6. Place a piece of rubber or plastic hose over each connecting rod cap bolt to protect the crankshaft journal and cylinder wall when removing the piston (see illustration).

13.6. To prevent damage to the crankshaft journals and cylinder walls, before removing the pistons, put pieces of rubber or plastic hoses on the connecting rod bolts

7. Remove the bearing shell and push the piston and connecting rod assembly out through the holes in the top of the engine. Use a wooden or plastic hammer handle to press down on the upper surface of the connecting rod bearing. If resistance is felt at the same time, it is necessary to check again whether the protrusion on the cylinder has been completely removed.

8. Repeat this procedure for the remaining cylinders.

9. After disassembly is complete, install the connecting rod bearing caps and shells onto their connecting rods and hand-tighten the nuts onto the caps. You can leave the old bearing shells in place until you begin assembly, as this will protect the connecting rod bearing surfaces from accidental scratches or damage.

10. Do not separate the pistons from the connecting rods (see more information in section 18).