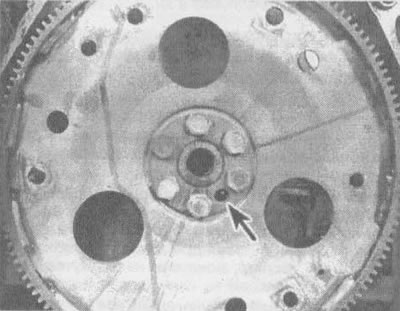

2. If the dowel pin is missing (see illustration) or the bolt holes are not staggered, scratch or paint a mark on the flywheel and crankshaft to ensure that they are reinstalled correctly in the future.

27.2. Most flywheels have dowel pins (indicated by an arrow). If the flywheel does not have such a pin, scratch or draw some marks to ensure proper installation later

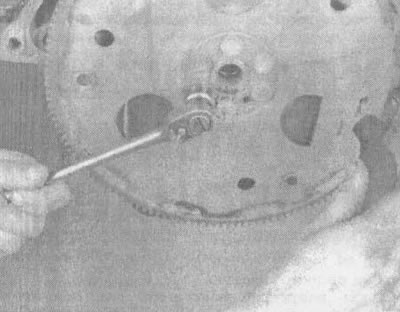

3. Remove the bolts securing the flywheel to the crankshaft (see illustration). Prevent the crankshaft from rotating by inserting a large screwdriver into the hole in the flywheel.

27.3. By inserting a large screwdriver into one of the holes in the flywheel, you can lock the flywheel when loosening and tightening the bolts

4. Remove the flywheel from the crankshaft.

5. Clean the flywheel of grease and oil. Inspect and check for damage to the surface of the flywheel and its ring gear.

6. Clean and inspect mating surfaces of flywheel and crankshaft. If there is a leak through the crankshaft rear oil seal, then this oil seal must be replaced before installing the flywheel in its original place (see section 25).

7. Position the flywheel against the crankshaft. Ensure alignment of marks made during removal (if the pin is missing and the arrangement of the bolt holes is staggered). Apply sealant to the threads before screwing in the bolts.

8. After locking the flywheel through the hole, tighten the bolts to the torque specified in specifications of this chapter.

9. Remaining installation operations are carried out in reverse order.