Note. Since there is not enough space in the car's engine compartment to remove the camshaft, for this procedure, the engine is removed from the car and mounted on a stand.

Checking the lifting height of the cam circuit

At the established head of cylinders See an illustration 12.3.

1. In order to check the degree of wear of the cams of the shaft, before removing the camshaft, the lift of the cam circuit should be checked. Remove valve covers (for 3.1 l engine - see section 5, part 2.1; for 3.8 l engine - see section 5, part 2.2).

2. Set piston N1 to TDC on the compression stroke (3.1L engine: see section 3, part 2.1; 3.8L engine: see section 3, part 2.2).

3. Starting with cylinder 1 valves, attach a dial indicator to the engine and position the plunger against the top surface of the first rocker arm. The plunger must be in line with the push rod (see illustration).

12.3. To check the lift height of the cam circuit, position the indicator plunger just above the push rod (on one line)

4. Set the indicator scale to zero, then slowly turn the crankshaft in the direction of rotation (clockwise), until the indicator hand stops and starts moving in the opposite direction. The stop point corresponds to the maximum lift of the cam contour.

5. Record the reading for future reference and set the piston back to TDC on the compression stroke.

6. Move the indicator to another rocker arm of the 1st cylinder and repeat the test. Remember to record the results for each valve.

7. Repeat the test procedure for the remaining valves. Because each piston must be at TDC on the compression stroke, measure from cylinder to cylinder according to the cylinder firing sequence.

8. After completing the test, compare the results with "technical data" at the beginning of the chapter. If the cam lift is less than the prescribed value, then there is wear on the cams, which means that the camshaft needs to be replaced.

At the removed head of cylinders See an illustration 12.9.

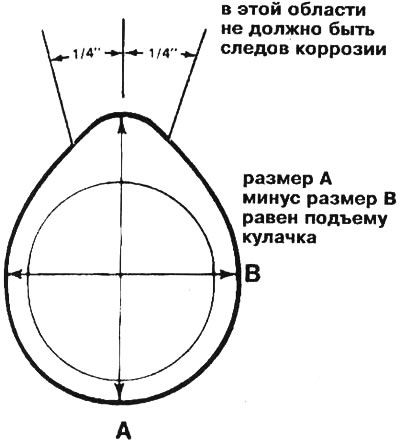

9. If the cylinder head has already been removed, an alternative method of measuring the contour of the cams can be used. Remove the camshaft as described later in this section. Using a micrometer, measure the maximum size of the cam contour (from base to highest point). Then measure the base diameter in a direction perpendicular to the direction of the previous measurement (see illustration). Take these measurements for all cams and record the results.

12.9. To check the lift height of the cam circuit, measure the maximum (A) and minimal (IN) diameters - to get the lift value, subtract the minimum diameter from the maximum diameter

10. Subtract the base diameter value from the cam contour height. This difference is equal to the lift of the cam contour. See point 8 above.

Withdrawal

11. Remove the drive chain and timing sprockets, pushers and push rods (3.1 l engine: see part 2.1, sections 5, 10, 13 and 14; 3.8 l engine: see part 2.2, sections 5, 8, 13 and 16).

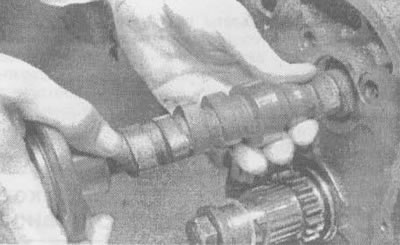

12. Turn away bolts of fastening of a persistent flange of a camshaft to the block of cylinders. Thread long bolts into the bolt holes on the camshaft sprocket to use them as a handle when removing the camshaft from the block (see illustration).

12.12. Screw long bolts into the bolt holes to use them as a handle when removing and installing the camshaft

Note. To remove and install the balance shaft (3.1L engine only) special equipment is required. If the bearings are in poor condition, the balance shaft must be replaced by an auto repair shop (see paragraph 19).

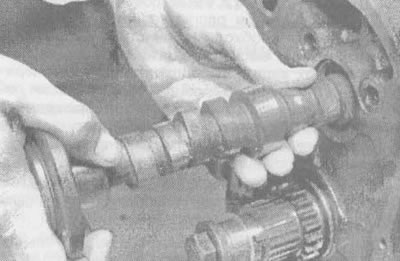

13. Carefully remove the camshaft from the block so that the cams do not damage or scratch the bearings (see illustration).

12.13. To check the lift height of the cam circuit, position the indicator plunger just above the push rod (on one line)

Examination

14. After removing the camshaft from the engine, it must be cleaned with a solvent and dried. Then check for signs of uneven wear, corrosion and scoring on the shaft journals under the bearings. If the journals are damaged, then most likely the bearing shells in the block are also damaged. In this case, it is necessary to replace both the camshaft and the bearings.

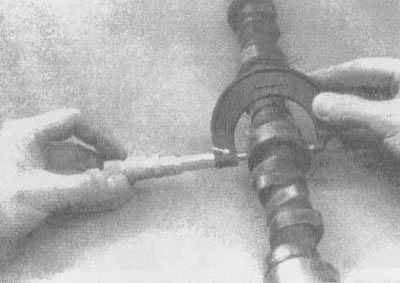

15. Measure the bearing journals with a micrometer (see illustration) to check for excessive wear or out-of-roundness.

12.15. Measure bearing journal diameters for excessive wear or out-of-roundness

16. Check the camshaft for signs of thermal discoloration, scratches, corrosion and uneven wear. If the condition of the cams is satisfactory, and the cam lift is within acceptable limits, the camshaft is suitable for further use.

17. Check the bearings in the block for wear and damage. Check for nicks, corrosion and discoloration.

18. The inside diameter of each bearing can be determined using a bore gauge and an outside micrometer or an inside micrometer. By subtracting the diameter of the bearing journal from the inner diameter of the corresponding bearing, you get the bearing clearance. If the clearance exceeds the allowable value, it is necessary to install new bearings, regardless of the condition of the old ones.

19. Replacing the balance and camshaft bearings requires special tools and skills, which makes this operation impossible to do at home. Therefore, for the qualitative performance of this work, it is necessary to send the unit to a car repair shop.

20. Installing and adjusting the balance shaft gear is described in section 24.