Note. If the engine is overheated, the cylinder head may be deformed (see point 12).

Cleaning

2. Remove the remnants of gaskets and seals from the surfaces of the cylinder head mating with the gasket, intake and exhaust manifolds. Be careful not to damage the cylinder head. You can use softening pads and special removal fluids that make it easier to remove pads, which are sold in car dealerships.

3. Remove the formed deposits from channels for a cooling liquid.

4. Using a stiff wire brush, clean the various openings to remove deposits that have formed there.

5. Using an appropriately sized tap, drive through the threads and remove any rust and sealant residue, if any, from all threaded holes. If compressed air is available, use it to remove the resulting dirt.

Attention! Wear protective goggles when using compressed air.

6. Clean the threads of the rocker arm bolts or studs with a wire brush.

7. Wash the cylinder head with solvent and dry thoroughly. Compressed air will speed up the drying process and ensure that all holes and pitted surfaces are clean.

Note. There are chemical carbon removers available commercially that can be helpful in cleaning cylinder heads and valve parts. However, they are very caustic and must be used with care. Strictly follow the instructions on the package.

8. Clean rocker arms, axles, bolts and push rods with solvent and dry thoroughly. Compressed air will speed up the drying process and clean the oil lines.

9. Clean the valve springs, spring seats, valve turning mechanisms, crackers and spring plates and dry them thoroughly. In order not to mix up the parts, process the parts of one valve at the same time.

10. Remove any visible deposits from the valves, and then, using a brush on the electric motor, remove deposits from the poppets and valve stems. Again, be careful not to mix up the valves.

Examination

Note. Before deciding on the amount of work to be carried out at the auto repair shop, be sure to complete all of the following inspection procedures. Make a list of details that require special attention.

Cylinder head

11. Carefully inspect the cylinder head for cracks, coolant leaks, and other damage. If there are cracks, consult the workshop about the possibility of repair. If repair is not possible, a new cylinder head must be purchased.

12. Using a straight edge and a feeler gauge, check for deformation of the cylinder head surface in contact with the gasket (see illustration). If the amount of deformation exceeds the value indicated in the technical data at the beginning of the chapter, the surface can be refinished by an auto repair shop.

9.12. Check the gasket-to-gasket surface of the cylinder head with a feeler gauge and straight edge for deformation (find the value of the maximum allowable deformation in the technical data of this chapter and use a feeler gauge of this thickness)

Note. If the head surfaces are machined, the intake manifold flanges must also be machined.

13. Check the valve seats in each combustion chamber. If there are signs of corrosion, burnout or cracks, then the head cannot be restored at home.

14. Check the valve stem clearance in the guide sleeve by measuring the lateral movement of the valve stem with an indicator mounted on the head (see illustration). The valve should be in the guide and protrude approximately 1/16" from the seat. To obtain the clearance value, it is necessary to divide the total valve movement indicated by the indicator by two. If after this you still have doubts about the condition of the valves, they should be checked by an auto repair shop.

9.14. A micrometer can be used to measure the valve stem clearance in the guide sleeve

Valves

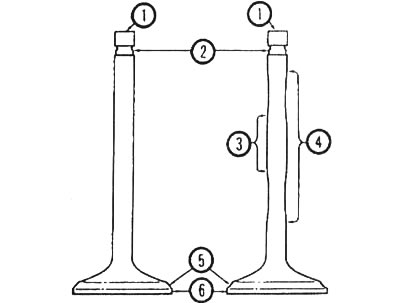

15. Carefully examine the bevel of each valve for areas of uneven wear, deformation, cracks, corrosion, and fading. Check for signs of galling, burrs on the valve stem and cracks on the neck. Rotate the valve to reveal a visible bend. Look for signs of corrosion and excessive wear at the end of the rod. Any of the above defects (see illustration) indicates that the valve needs to be processed in a car repair shop.

9.15. Check valve wear at the points indicated here: 1 - valve stop, 2 - cracker grooves, 3 - stem (minimum wear area), 4 - rod (area of maximum wear), 5 - chamfer of the valve, 6 - edge

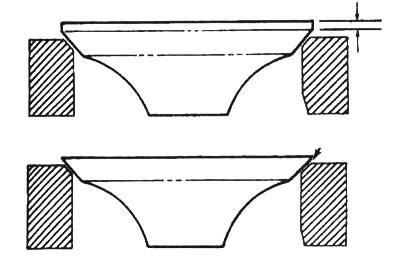

16. Measure the edge thickness of each valve (see illustration). If the lip width is less than the value given in the technical data, the valve must be replaced with a new one.

9.16. The edge width on each flap must be equal to the prescribed value (if the lip is missing, the valve cannot be reused)

Valve parts

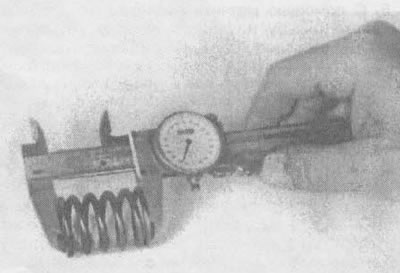

17. Check for signs of corrosion and wear on the springs of each valve (at the ends). Measure free (unloaded) length and compare with the technical data at the beginning of the chapter (see illustration). All springs that are shorter than the prescribed value must be replaced. Before deciding on the possibility of using springs in a rebuilt engine, check their tension using a special device (take the springs to the workshop to check).

9.17. Measure the free length of each valve spring with a caliper

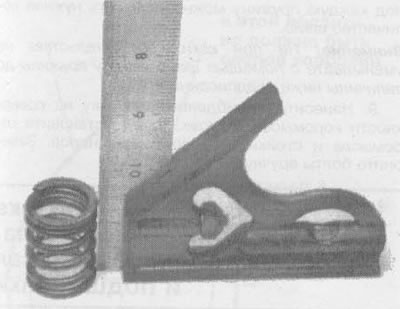

18. Place each spring on a flat surface and check for straightness (perpendicularity) (see illustration). If any spring is bent or sagging, replace it with a new one.

9.18. Check the verticality of each valve spring

19. Check for visible signs of wear or cracks on plates and crackers. All doubtful parts must be replaced with new ones, since their failure during engine operation will lead to serious damage.

Rocker arm parts

20. Check if there are rocker arms on the front surfaces (in areas that come into contact with the ends of the tappets and valve stems) traces of corrosion, wear, abrasion, scratches, roughness. Also check the contact surfaces of the rocker arms, racks and the racks themselves. Check for cracks on each rocker arm and bolt.

21. Check for signs of scoring and excessive wear at the ends of the rods. Roll each rod across a smooth surface (e.g. on glass), to determine if it is bent.

22. Check up a condition of a carving in all apertures under bolts of yokes in heads of cylinders.

23. All damaged and excessively worn parts must be replaced with new ones.

All details

24. If the test results indicate a general unsatisfactory condition of valve parts and their wear beyond acceptable limits (which, as a rule, takes place when it is necessary to overhaul the engine), Valves need to be resurfaced or replaced (valve maintenance recommendations are given in section 10).