2. Before honing the cylinders, install the main bearing caps and tighten the bolts to the torques given in "Technical data" at the beginning of the chapter.

3. Two types of cylinder hones are commonly used - glass bead hones ("bottle brush") or a traditional surface hone with abrasive bars on springs. You will also need some honing oil (if there is no special oil, kerosene will do), rags and electric drill. Proceed as follows.

- A) Install the hone in the electric drill, squeeze the bars and insert it into the first cylinder (see illustration). Be sure to wear safety goggles or a mask.

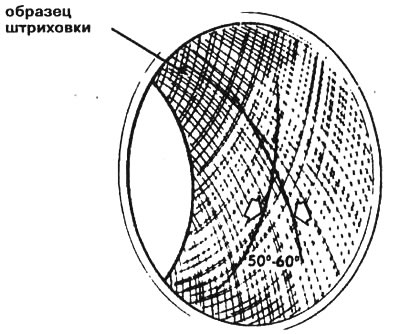

- b) Lubricate the cylinder with plenty of honing oil, turn on the drill and move the honing tool up and down in the cylinder at a speed that produces the desired crosshatch pattern on the cylinder walls. Ideally, hatch lines should intersect at a 45°angle (see illustration). Be sure to apply plenty of oil and choose more surface material than required to achieve the desired wall condition.

Note. Piston ring manufacturers can specify different mesh hatch angles. Follow the instructions that come with new rings.

- V) Do not remove the moving hone from the cylinder. Turn off the drill and continue to move the hone up and down the cylinder until it comes to a complete stop, then squeeze the hone and remove it. If you are using hon type "bottle brush", turn off the drill and, turning the drill chuck in the direction of normal rotation, remove the hone from the cylinder.

- G) Remove oil from the cylinder walls and repeat the procedure for the remaining cylinders.

17.3a. If you have never honed cylinders before, it is preferable to use a honing type "bottle brush" |

17.36. The hone for the cylinder should leave a smooth reticulate shading in which the lines intersect at an angle of approximately 90° |

4. After finishing the honing procedure, file the upper edges of the cylinders with a fine-grained file so that the pistons do not seize during installation. Be careful not to scratch the cylinder walls with the end of the file.

5. Then wash the cylinder block thoroughly again with warm soapy water to remove all traces of abrasive dust formed during honing.

Note. Cylinders can be considered clean if, after wiping the walls with a white, lint-free cloth moistened with clean engine oil, no honing residues accumulate on the cloth, which appear as gray spots. Be sure to brush out all oil holes and lines and rinse them under running water.

6. After rinsing, dry the block and coat all treated surfaces with light anti-rust oil. Cover the unit with plastic wrap to keep it clean until assembly.