12.37. Idle Air Control Valve (IAC) can be unscrewed with an adjustable wrench (shown in the illustration) or 1 1/4" wrench

38. Remove the old IAC valve gasket. Clean the throttle body surface of the old gasket material to ensure the correct position of the new gasket.

39. All valve stems in IAC valves on TBI Model 220 units have the same double cone. However, the axles on some blocks are 12mm in diameter, while others are 10mm in diameter. When replacing an IAC valve, the new valve must have the correct axle cone diameter and the correct diameter to properly seat the valve in the throttle.

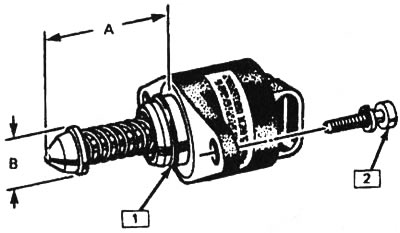

40. Measure the distance between the end of the axle, in its fully extended position, and the mounting surface of the housing (see illustration). If the distance "A" greater than specified in the specifications in this chapter, it must be reduced to prevent damage to the valve.

12.40. Flanged type IAC valve for injection system model TVI 220: A - camshaft extension distance, B - camshaft diameter, 1 - O-ring, 2 - screw and washer

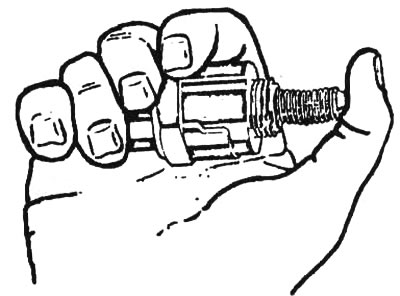

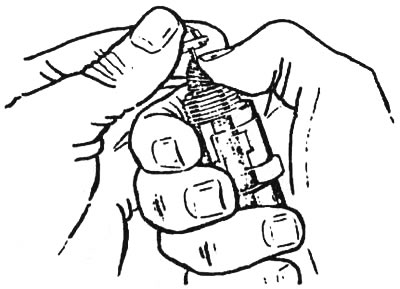

41. If you need to adjust the axis, determine if your valve belongs to type 1 (there is a collar around the electrical terminal) or to type 2 (bead missing).

- A) To adjust the flanged IAC valve shaft, hold the valve and push the shaft with your thumb while rocking it from side to side (see illustration).

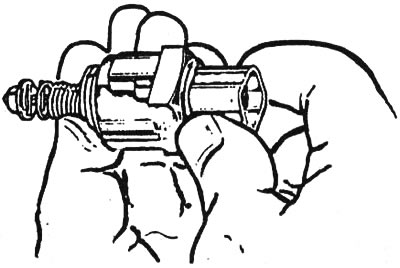

- b) To adjust the ribless IAC valve stem, compress the retaining spring while turning the stem clockwise (see illustration). Return the end of the spring to its original position by aligning the straight part in the groove under the flat surface of the valve (see illustration).

12.41a. To adjust the flanged IAC valve, press hard on the axle with your thumb while rocking the axle slightly from side to side |

12.41 b. To adjust an IAC valve without a collar, compress the valve retaining spring while turning the shaft clockwise... |

12.41 c....then return the end of the spring to its original position by aligning the straight part in the groove under the flat surface of the valve

42. Install the IAC valve and tighten the screws securely. Connect the electrical connector.

43. Install the air filter, adapter and gaskets.

44. Connect the wire to the battery.

45. Start the engine and wait for it to reach operating temperature, then turn it off. No adjustments to the IAC valve are required after installation. IAC valve electrically "dumped" the ECM after the engine is turned off.