Note. The test described below is carried out under the condition that the fuel pump is running and that the correct fuel pressure is maintained (see section 3).

Preliminary checks

1. Check all electrical connections associated with the system. Bad electrical contacts and broken wire "masses" can cause a lot of trouble leading to more serious malfunctions.

2. Make sure the battery is fully charged, as accurate voltage readings are essential for correct fuel quantity readings.

3. Check the air filter element: a dirty or partially clogged filter will greatly reduce performance and economy (see chapter 1).

4. If a blown fuse is found, replace it and check if it blows again. If this happens, look for a short in the wiring harness going to the fuel pump.

Only for engines with PFI system

5. Check the air intake from the air flow sensor (MAF) (in the presence of) to the intake manifold for leaks that will result in a lean mixture. Also check the condition of the vacuum hoses connected to the intake manifold.

6. Disconnect the air intake and check for dirt, soot or other residual deposits on the walls of the throttle body and especially around it. If there is dirt, clean the throttle body with a carburetor cleaner.

7. With the engine running, place a screwdriver on each injector in turn and listen through the handle for a click indicating correct operation.

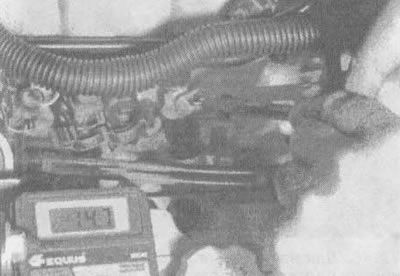

8. Turning off the engine and disconnecting the electrical connector from the injector, measure the resistance of each injector (see illustration). Each nozzle should have a resistance of approximately 14.7 ohms. If this is not the case, then the injector is faulty.

11.8. Measure the resistance of each injector with a digital ohmmeter

9. Other system checks must be carried out by the company's service department "General Motors" or a qualified workshop, as the control unit may be damaged (if it doesn't work properly).

Only for engines with TBI system

10. Put the car on the parking brake, remove the air filter cover and with the engine running at idle with the gear lever in the parking position, observe the operation of the nozzles. The atomized fuel should form an even cone that should reach the throttle valve opening.

- A) If the spray cone is loose or uneven, the nozzle is either clogged or defective. Sometimes gasoline additives designed specifically to clean injectors can help. If they do not help, then the car service centers have more effective cleaning equipment.

- b) If the injector does not work at all, check the electrical connector. If the contact is good and the injector is receiving voltage, but the injector still does not work, then it is faulty.