Warning 1. Gasoline is extremely flammable and extra precautions are required when working with any part of the fuel system.

Warning 2. After relieving fuel pressure, wrap a rag around any fuel connection you will be disconnecting. It will absorb any remaining fuel that may leak out. This will reduce the risk of fire and prevent fuel from coming into contact with your skin.

1. Before servicing any part of the fuel system, relieve fuel pressure to minimize the risk of fire or injury.

2. Remove the cap from the tank neck; this will relieve the pressure remaining in the tank.

Engine 3.1L (Model 220 TBI System)

3. Vehicles with the TBI system have a fuel pressure regulator which is designed to keep the fuel circulating continuously, resulting in automatic pressure relief. Therefore, there is no need for a special fuel pressure relief procedure. After switching off the ignition, it takes about 10 minutes for the fuel pressure to be relieved.

3.8L engine (PFI system)

4. On PFI models, use one of the following two methods to relieve fuel pressure:

- A) Disconnect the fuel pump electrical connector at the fuel tank (lower the tank if necessary). Start the engine and wait until it stops, then run the starter for another three seconds. Turning off the ignition (turning the key to position "OFF"), reconnect the fuel tank electrical connector, then disconnect the wire from the negative battery terminal.

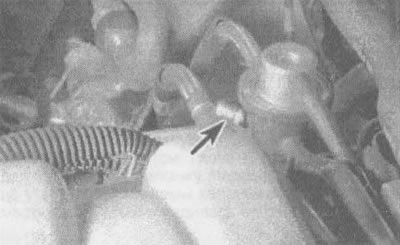

- b) Remove the cap from the filler neck of the tank. Connect fuel gauge (J34730-1) or similar to the valve on the fuel rail (see illustration). Place the bleed hose on the pressure gauge into a special container with fuel. Open the valve on the gauge to relieve pressure, then disconnect the wire from the negative battery terminal.

2.4. Unscrew the cover (arrow) from the pressure regulator and connect the fuel pressure sensor

5. If this work is not done before servicing the fuel lines or connections, fuel splatter and personal injury may occur.