Note. To perform a fuel pressure test, you need a fuel pressure gauge and an adapter kit to test the fuel injection system.

Preliminary check (all models)

1. If the fuel system is not working due to an interruption in the supply of the required amount of fuel, inspect the fuel system as follows.

2. First of all, make sure there is fuel in the gas tank.

3. With the engine running, inspect each fuel line connection at both ends for leaks. Eliminate leaky connections (couplings, pipelines). Check all hoses for kinks or kinks that could be restricting fuel flow.

Pressure test

4. Relieve the pressure in the fuel system (see section 2).

Vehicles with PFI multipoint injection system (engine 3.8 l)

5. Install fuel gauge (J-34730-1) at the pressure regulator valve (see illustration 2.4).

6. Turn the ignition key to position "ON" ("included"), by turning off the air conditioner. The fuel pump should run for about 2 seconds - note the pressure gauge reading. After stopping the pump, the pressure must remain constant. It must be within the range specified in the specifications of this chapter.

7. Start the engine and let it idle at normal operating temperature. The pressure should drop by 3-10 psi. If all pressures are within the range described in the specifications in this chapter, the system is operating normally.

8. If the pressure does not drop by 3-10 psi after starting the engine, apply a vacuum of 12-14 inches to the pressure regulator. If the pressure drops, repair the vacuum corrector in the pressure regulator. If pressure does not drop, replace regulator.

9. If the fuel pressure is out of specification, check as follows:

- A) If the pressure is higher than specified, check the regulator for damage, kinking, or obstruction of the fuel bypass hose or tube.

- b) If the pressure is lower than specified in the specifications:

- V) Check the fuel filter - make sure it is not clogged.

- G) Look for kinked or clogged fuel hoses between the fuel tank and fuel rail.

- d) Check the pressure regulator for correct operation.

- e) Inspect the fuel line for leaks.

- and) Look for kinks, breaks, or disconnection on the vacuum corrector hose.

- h) Check the injectors for leaks.

- And) Check the fuel pump valve inside the tank.

10. After completion of work, relieve fuel pressure (see section 2) and remove the gauge

11. If there are no problems with the system parts described above, check the fuel pump (see below).

Cars with central injection system TV! (engine 3.1 l)

12. Relieve the pressure in the fuel system (see section 2).

13. Install a fuel gauge between the fuel supply hose and the throttle body inlet. The fuel lines will be under high pressure during this test, so make sure the connections are secure to prevent leaks.

Note. If you don't have fasteners (adapters) to connect the fuel line to the pressure gauge, use the special tool available from the parts store.

14. Turning off the ignition, connect a 12 V voltage source through a wire equipped with a fuse to the control terminal of the fuel pump (red wire) and note the pressure value (see illustration).

3.14a. The control terminal of the fuel pump is located near the battery

{{Открыть большую картинку в новом окне}} »

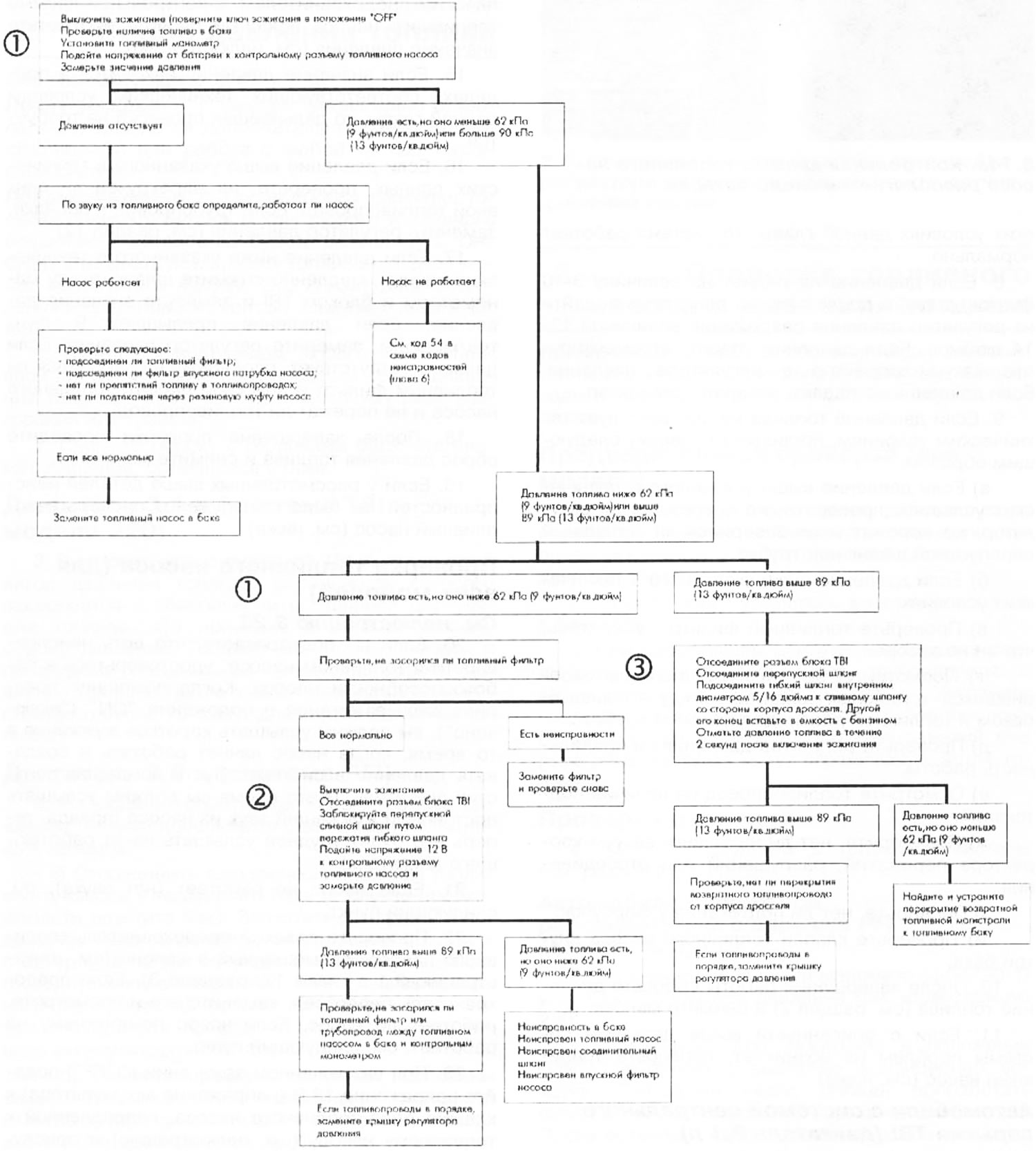

3.14b. Scheme for checking the fuel system of an engine with a displacement of 3.1 liters

15. If the pressure value is within the specifications of this chapter, then no further verification is required.

16. If the pressure is higher than specified in the technical data, check if the fuel drain line is kinked. If the piping is OK, replace the pressure regulator (see section 12)

17. If the pressure is lower than the specification, slowly squeeze the hose between the pressure gauge and the TBI block and read the pressure. If pressure is greater than 9 psi, replace pressure regulator. If there is no pressure, check for clogged fuel filter and fuel pump inlet filter, and for a kinked fuel line.

18. After completing the test, relieve the fuel pressure and remove the pressure gauge.

19. If no faults were found in the above parts, check the fuel pump (see below)

Fuel pump check (for all models)

20. If you suspect that there is a malfunction in the fuel pump, make sure the pump is working. When the assistant turns the ignition key to the "ON" ("included"), you should hear a short buzzing sound as the pump begins to run and pressurize the system. Have an assistant start the engine. At this time, you should hear a constant buzzing sound from the pump (however, now it will be more difficult to hear because of the running engine)

21. If the pump does not work (no sound), see the next paragraph.

22. Check the fuel pump fuse located in the passenger compartment (see illustration 3.1 in chapter 12, section 3). If the fuse is blown, replace it and see if the pump works. If the pump still does not work, see the next point.

23. With the ignition off ("OFF") apply 12V voltage (battery voltage) to the fuel pump relay terminal routed to the fuel pump (see illustration) and listen to see if the fuel pump is running.

3.23. Apply voltage from the battery to the gray wire at the fuel pump relay terminal and listen for the fuel pump to start

Note. The location of the relay is indicated on illustrations 6.2a and 6.26 in chapter 12, section 6.

24. If the pump is running, check the fuel pump relay. If the pump does not work, check the circuit between the relay and the fuel pump for an open. If the circuit is not open, disconnect the electrical connector at the fuel pump. Apply battery voltage to the pump terminal with the gray wire. Connect the terminal with the black wire to "mass". If now the fuel pump has started working, then everything is in order; check all connectors and wires again. If it does not work, then the pump is out of order. Replace fuel pump.

Checking the fuel pump relay (for all models)

25. To test the fuel pump relay, disconnect the relay (see illustrations 6.2a and 6.26 in chapter 12) and connect a test lamp to the dark gray and white terminal and have your assistant turn the ignition key to "ON" ("included") (see illustration). For 2-3 seconds, the control lamp should light up and turn off by itself.

3.25. With the key in the ignition switch, check for battery voltage at the dark gray and white fuel pump relay connector terminal (3.1 engine parts shown)

26. If the test passes, but the fuel pump relay does not work (if it works, you should hear the relay click when the assistant turns the ignition key to "ON"; if the relay is connected), replace the fuel pump relay with a new one. If there is still no voltage, check the ECM/PCM and fuel pump circuits for shorts and open circuits.