2. Raise the vehicle and support it securely on stands.

3. Drain engine oil and change oil filter (see chapter 1, section 12).

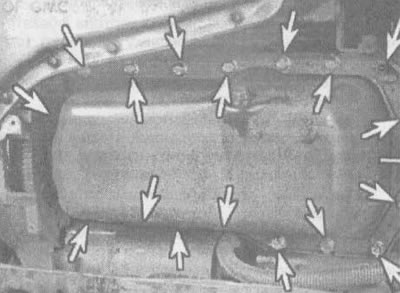

4. Turn away bolts of fastening of an oil case (see illustration) and carefully separate the crankcase from the block. To avoid damage to the sealing surface on the flange and, as a result, oil leakage from the engine, it is not allowed to insert the lever between the mating surfaces of the crankcase and block. To separate the crankcase, tap it with a soft-faced hammer.

17.4. Bolts of fastening of an oil crankcase (shown by arrows) located around the perimeter (bottom view)

5. Clean the oil sump with a solvent and remove the remnants of the old gasket material and sealant from the mating surfaces, check the cleanliness of the bolt holes in the cylinder block. Check the oil sump flange for buckling, especially around the bolt holes. If necessary, support the crankcase on a piece of wood and use a hammer to flatten the surface of the gasket.

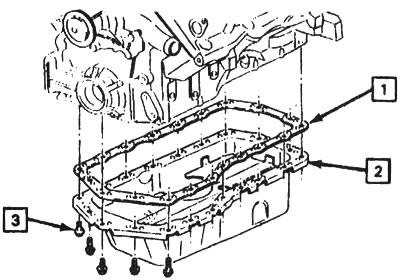

6. When installing the oil sump, be sure to replace the old gasket with a new one (see illustration).

17.6. Oil sump: 1 - gasket, 2 - crankcase, 3 - bolts

7. Establish an oil case on the block of cylinders and wrap bolts.

8. Tighten the bolts to the torque specified in the specifications in this chapter. The final tightening is done in three steps, starting from the center, crosswise.

9. Remaining operations are carried out in reverse order.

10. Fill the engine with oil (see chapter 1, section 12), start it, let it warm up to normal operating temperature and check for leaks.