Withdrawal

2. Remove the timing chain cover (see section 13).

3. Temporarily screwing the antivibrator mounting bolt into the crankshaft, turn the crankshaft with this bolt with a wrench until the ignition setting marks on the crankshaft and camshaft sprockets align with the marks on the antivibrator (see illustrations). In this case, the pistons of the 1st and 4th cylinders must be at TDC, and the piston of the fourth cylinder must be on the compression stroke (this can be verified by checking the position of the ignition distributor rotor, which should point to the ignition wire of the fourth cylinder spark plug on the distributor housing cover).

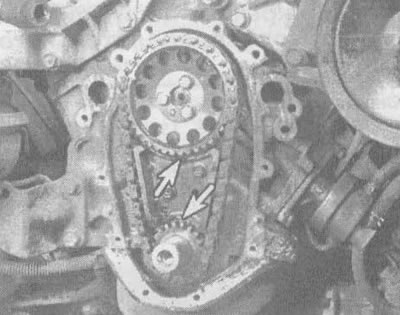

14.3a. Ignition setting marks (shown by arrows) must be aligned as shown in the photo: a straight line must pass through the center of the camshaft, the mark on the camshaft sprocket, the mark on the crankshaft sprocket and the center of the crankshaft (the damper also has two risks used when adjusting) |

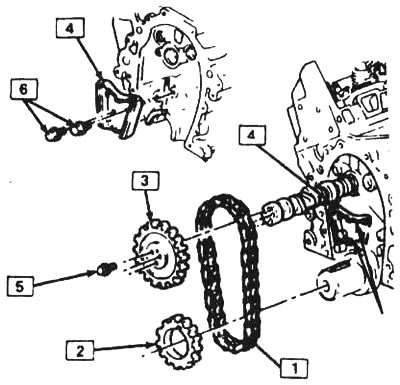

14.3b. Camshaft drive chain and related parts: 1 - chain, 2 - crankshaft sprocket, 3 - camshaft sprocket, 4 - damper, 5 - camshaft sprocket mounting bolts (3 pieces), 6 - stabilizer fastening bolts (2 pieces) |

Note. Do not attempt to remove sprockets or chain until this procedure has been completed, and do not rotate the crankshaft or camshaft after removing sprockets or chain.

4. Turn away bolts of fastening of an asterisk of a camshaft (see illustration). When performing this operation, do not allow the camshaft to rotate (if this happens, re-align the ignition marks and only then unscrew the bolts).

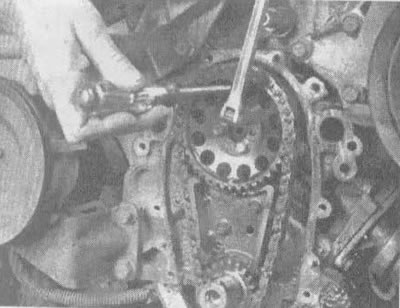

14.4. A screwdriver will prevent the camshaft sprocket from turning when the bolts are loosened

5. Remove the camshaft sprocket. If the sprocket is stuck, gently tap one side of the sprocket with a plastic-headed hammer. Together with the sprocket, remove the camshaft drive chain from the engine.

6. Chain and camshaft sprocket must be stored in sets. If you are going to install a new chain, use a puller to press the sprocket off the camshaft and install a new one. When installing the sprocket, align the keyway machined in the sprocket with the key on the camshaft.

7. Check the damper for the timing chain for cracks and signs of wear and, if necessary, replace it with a new one. The damper is attached to the cylinder block with two bolts.

8. Clean chain and sprockets with solvent and dry with compressed air.

Attention! Be sure to wear protective goggles when using compressed air.

9. Check all parts for signs of wear and damage. Pay attention to the technical condition of the sprocket teeth: they should not have chips, cracks, as well as signs of chipping and warping.

Installation

10. Lubricate the bearing (back) camshaft sprocket surface with molybdenum grease or machine oil for engine assembly (see illustration). Install a slack drive chain over the sprocket.

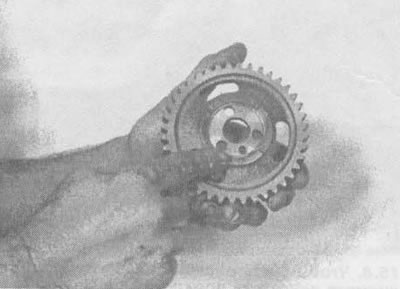

14. 10. Before installing the sprocket on the camshaft, apply grease to its bearing (back) surface

11. Aligning the ignition setting marks (see illustration 14.3a), run the chain over the sprocket and install the sprocket onto the camshaft. If necessary, tighten the sprocket onto the shaft by tightening the three bolts. It is unacceptable to put it on with a hammer - this can lead to displacement of the concave plug at the other end of the camshaft. Tighten the bolts to the specified torque.

12. Again make sure that the ignition installation marks are aligned. If they do not match, remove the sprocket from the camshaft and run the chain until they are aligned.

13. If you need to set the N1 piston to TDC on the compression stroke (for example, to simplify the installation of the ignition distributor after replacing the camshaft), turn the crankshaft one full turn (360°): The marks on the crankshaft and camshaft will move to the 12 o'clock position. However, if the ignition distributor has not been replaced, this operation is not necessary.

14. Lubricate the chain and camshaft sprocket with clean engine oil. Reinstall the chain cover (see section 13).

15. Remaining operations are carried out in reverse order.