Attention! When performing the procedures discussed below, it is recommended to use the appropriate techniques and devices. Be careful not to get under the engine when it is jacked up. Failure of the jack can result in serious injury or even death.

1. Engine mounts are generally virtually maintenance-free, but should they break or become damaged, they must be replaced immediately, otherwise the extra stress on the transmission could result in damage or premature wear.

Examination

2. During the test, the engine should be slightly raised so that the mounts are unloaded.

3. Raise the vehicle and place it securely on stands. Place a block of wood between the jacking pad and the oil sump, then carefully lift the engine just enough to relieve the mounts.

4. Check the bearings for defects such as hardening, cracking and peeling of rubber from metal plates. Sometimes cracking occurs right in the center of the rubber element.

5. Check for movement of support plates and motor or frame (using a large screwdriver as a lever, push down on the rod to see if the support has shifted). If movement is detected, lower the engine and tighten the mount fasteners.

6. To increase the life of the supports, put on protective rubber boots on them.

Replacement

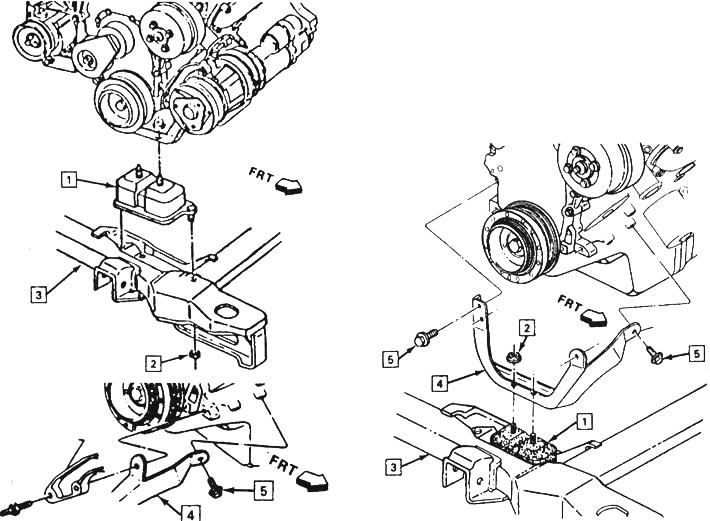

7. After disconnecting the cable from the negative battery terminal, raise the vehicle and place it securely on stands.

8. Remove the engine shock absorber (see illustration 4.4).

9. Raise the engine slightly with a jack or hoist. Loosen the bolts and separate the support from the frame (see illustration).

17.9. engine support (arrow with the inscription "FRT" points towards the front of the car): 1 - engine support, 2 - nut, 3 - subframe, 4 - bracket, 5 - bolt

10. Unscrewing the bolts (nuts) fastening the support bracket to the cylinder block, remove the support.

11. Installation of the support is carried out in the reverse order. Apply a coat of sealant to all fasteners and tighten securely.