2. Remove a cover and a rotor of the distributor of ignition.

3. Remove the ignition distributor from the engine (see section 8).

4. Disconnect from the block of ignition conclusions of the gauge.

Examination

5. Connect one end of the ohmmeter to the sensor terminal, and the second to "mass", as shown in the illustration. To check the wires for breaks, bend them by hand. The ohmmeter should always show "infinity". If this is not the case, then the sensor is defective and should be replaced.

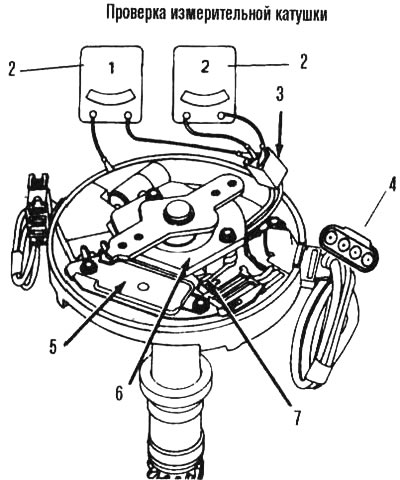

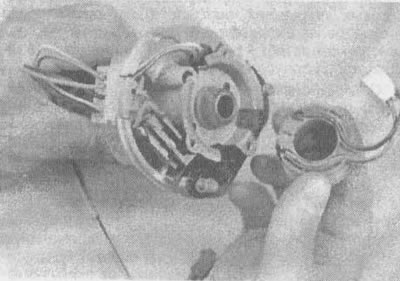

10.5. Checking the sensor on the ignition distributor of the system DO NOT! (for engines 3.1 l): 2 - ohmmeter, 3 - sensor leads disconnected from the ignition unit, 4 - 4-pin connector, 5 - ignition unit, 6 - sensor, 7 - contact "R"

6. Connect the ohmmeter leads to the terminals on the sensor leads. To check the wires for breaks, bend them by hand. When bending the wires, the ohmmeter should show a constant resistance value between 500 and 1500 ohms. If this is not the case, then the sensor is defective and should be replaced.

Replacement

7. Remove the spring from the axis of the ignition distributor.

8. Mark the distributor drive and shaft so that they can be easily assembled in the same position.

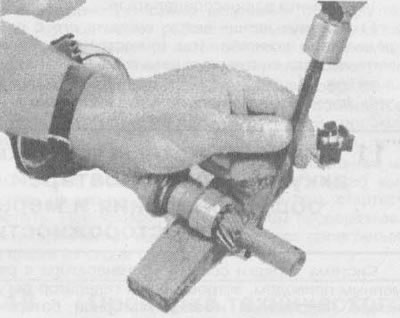

9. Carefully lay the ignition distributor on a wooden block and use a hammer and a punch to knock out the pin from the distributor shaft and gear (see illustrations).

10.9a. To remove the sensor, place the distributor shaft on a block of wood and use a punch and hammer to knock out the pin

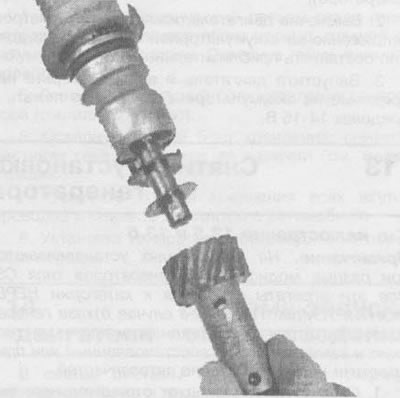

10.9b. Remove the driven gear with spacers from the shaft shank, paying attention to the order in which the washers are removed

10. Remove the distributor shaft.

10.10. Remove the shaft from the ignition distributor

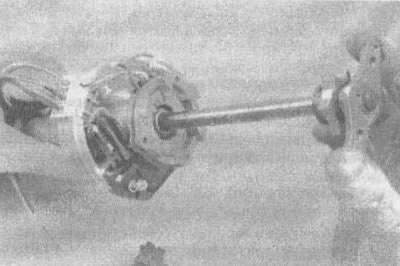

11. Pulling the sensor up, remove it from the ignition distributor (see illustration). Note the order in which these parts are removed.

10.11. To remove the sensor from the 3.1L engine ignition distributor, unscrew the bolts from the pole pieces and pull the coil up

12. Assembly is carried out in the reverse order.