Note. On vehicles with a 3.8L engine, it may be easier to change the spark plug in the rear (law) half-block of cylinders from below. If you wish to do so, jack up the vehicle and secure it on stands.

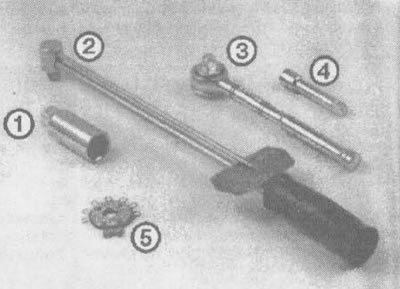

2. In most cases, the tools required to change spark plugs include: (spark plug keys are lined inside to prevent damage to the porcelain insulators), various accessories, nozzles and a feeler gauge for checking and adjusting the gaps on new candles (see illustration). There is a special tool for removing the tips from the spark plugs and it is convenient to use it on the described car models, since the tips are very tight. Use a torque wrench to tighten new spark plugs. It is also recommended to allow the engine to cool before removing or installing spark plugs.

32.2. Tools needed to change spark plugs:

1 - Candle socket wrench - this wrench has a gasket inside to protect the porcelain insulator of the spark plugs

2 - Torque wrench - although not required, using this tool is the best way to ensure that the spark plugs are properly tightened

3 - Ratchet - standard manual spark plug tool

4 - Nozzle - depending on the model and accessories, you may need special nozzles and universal joints in order to get any of the spark plugs

5 - Spark Plug Gap Gauge - This gap gauge is available in various versions. Check that the dipstick is suitable for your engine

3. The best approach to replacing spark plugs is to buy a complete set of new spark plugs in advance, adjust them to the correct gap, and change all of the spark plugs at the same time. When buying new spark plugs, check that the type of spark plug matches your car's engine. Candle type can be found in the section "Technical data" at the beginning of this chapter and on the label "Emission Control Information" ("Emissions Management Information"), located under the hood. If these two sources list different types of candles, refer to the value printed on the label.

4. Allow the engine to cool completely before changing spark plugs. While the engine is cooling, check the new spark plugs for defects and adjust their gaps.

5. Check the gap by inserting a feeler gauge of the appropriate thickness between the electrodes at the top of the spark plug (see illustration). The gap between the electrodes must be as indicated on the label "Emission Control Information". The probe should pass between the electrodes with little friction. If the gap is not correct, use the adjuster on the stylus body to bend the electrode slightly to achieve the correct gap (see illustration). If the side electrode is not positioned exactly above the center electrode, bend it so that it is positioned just below it. Check for cracks in the porcelain insulator (if they are, the candle cannot be used).

32.5a. Spark plug manufacturers recommend using a wire feeler when checking the gap - if the wire does not pass between the electrodes with little friction, adjustment is necessary |

32.5b. To change the gap, bend only the side electrode (as indicated by the arrows) and be very careful not to split or break the porcelain insulator surrounding the center electrode |

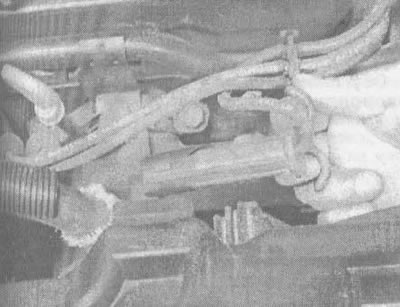

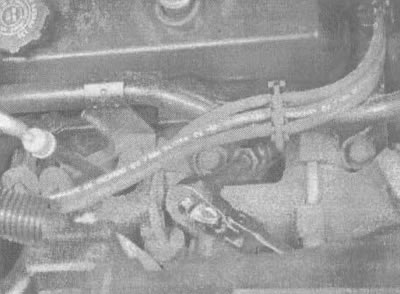

6. With a cold engine, remove the wire from one of the spark plugs. Pull only on the ferrule at the end of the wire, not on the wire itself. You can use a special tool to remove spark plug wires (see illustration).

32.6. When removing the wires from the spark plugs, pull only the cap, unscrewing and pulling it off the spark plug

7. If a compressed air source is available, use it to blow dirt or foreign bodies from the spark plug hole. A regular bicycle pump will also work. The general idea here is to ensure that no dirt enters the cylinder when the spark plug is removed.

8. Put the end head on the spark plug and unscrew the spark plug by turning it counterclockwise (see illustration).

32.8. To remove the spark plugs on this type of engine, you will need a socket and socket

9. Compare the spark plug with those shown in the photographs in this chapter to get an idea of the general condition of the engine.

10. Screw one of the new spark plugs in by hand, then tighten it with a torque wrench (if it exists) or with a ratchet. It is also recommended to pull a small piece of rubber hose over the end of the spark plug and use it as a screwing tool (see illustration). The hose will wrap around the plug just enough to turn it, but it will start to slip if the plug is not threaded - this will prevent damage to the threads and avoid costly repairs.

32.10. Using a 3/16" rubber hose will save time and prevent damage to threads when installing spark plugs

11. Before putting the spark plug wire on the spark plug, check it by following the procedures in section 33.

12. Install the spark plug wire onto the new spark plug by screwing it onto the tip until it seats on the spark plug.

13. Repeat the described procedure with other spark plugs, replacing them one at a time so as not to mix up the wires.