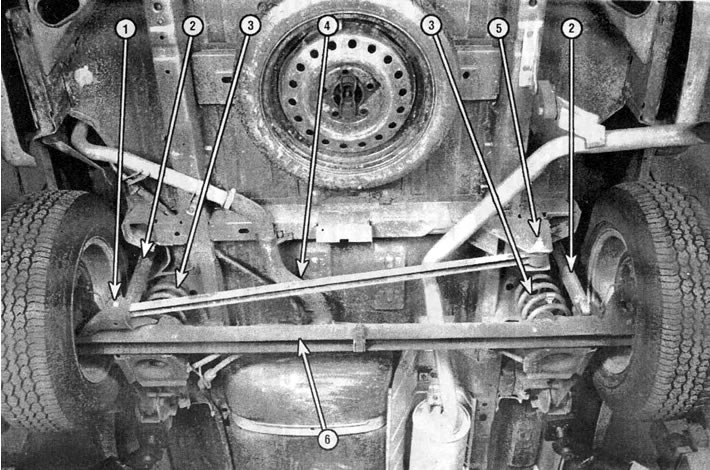

A feature of the rear suspension is the presence of an axle beam with coil springs, to which trailing arms and transverse jet thrust are connected (see illustration). Vibration damping is carried out by vertically mounted shock absorbers located between the axle and the chassis.

The rack and pinion steering mechanism is located behind the engine, it drives the steering rods connected to the steering knuckles. Usually (standard) there is hydraulic power steering, and the steering column is designed to fold in the event of a vehicle collision.

Note. Vehicles use both inch and metric systems for various suspension and steering parts, so you should have both types of tools before you begin.

Often when working with suspension and steering parts, you may encounter fasteners that seem impossible to unscrew. These parts are located underneath the vehicle and are constantly exposed to water, road grime, rust or freezing, making removal extremely difficult. To unscrew these parts without damaging them, a large amount of penetrating oil should be used, allowing it some time to soak. Using a stiff brush to clean the threads also makes it easier to loosen bolts and nuts and prevents damage to the threads. Sometimes a sharp blow with a hammer and punch will break the connection between the threads of the nuts and bolts, but care must be taken that the punch does not slip off the fastener and knock off the threads. Sometimes heat also helps "stuck" fasteners and surrounding areas, but this is not recommended as there is a risk of fire. You can use auxiliary attachments or rods, tubes to increase the shoulder, but never set the ratchet (ratchet) - this can damage it. Sometimes, when loosening, it makes sense to first tighten the nut or bolt before loosening them. If drastic measures had to be taken when unscrewing, such fasteners should be replaced with new ones during installation.

Since most of the operations described in this chapter involve working under the vehicle, a lift is required. It is preferable to use a stationary hydraulic lift, it can also be used to support certain parts during various operations.

Attention! Never rely on a jack alone or work under a vehicle when it is jacked up only. Whenever any suspension or steering parts are loosened or removed, they must be inspected and, if necessary, replaced with new parts of similar quality and design. It is necessary to strictly follow the specifications for tightening torques of threaded connections in order to properly assemble and fasten. Never attempt to heat or straighten any suspension or steering parts. Replace any warped or damaged parts with new ones.

Note. Before performing any operation that requires the battery to be disconnected on vehicles equipped with the Delco Loc II audio system, be sure to disable the system's interlock.

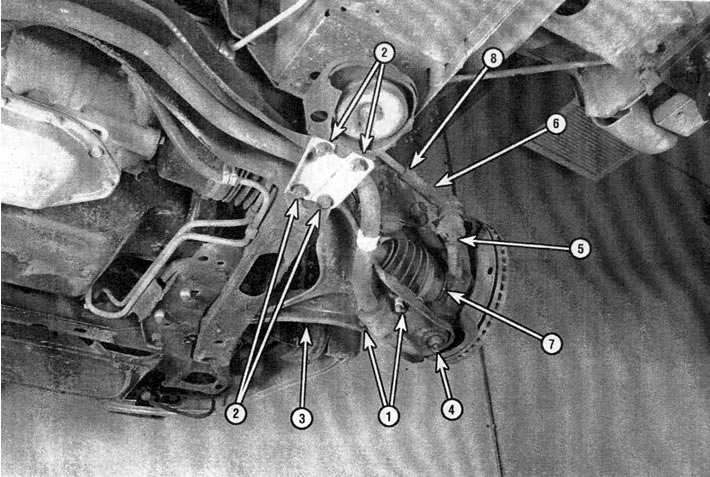

1.1a. Front suspension details: 1 - anti-roll bar collar clamp nuts, 2 - anti-roll bar booster nuts, 3 - lower arm, 4 - ball joint, 5 - external tie rod ball joint pin nut, 6 - external tie rod, 7 - knuckle, 8 - outer tie rod nut

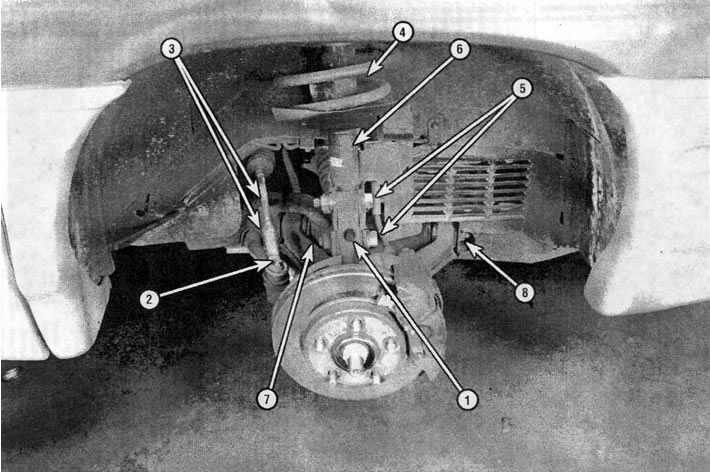

1.1b. Front suspension details: 1 - steering knuckle, 2 - outer tie rod, 3 - outer tie rod pin nut, 4 - coil spring, 5 - bolts and nuts for fastening the steering knuckle to the strut, 6 - strut assembly, 7 - lower arm, 8 - bolts and lower arm axle nuts

1.2. Rear Suspension Details: 1 - lower bolt for fastening the transverse reaction rod to the axle beam, 2 - shock absorber, 3 - coiled coil spring, 4 - transverse reaction rod, 5 - upper bolt of the bracket for attaching the transverse reaction rod to the body, 6 - axle beam