Attention! This operation should not be performed on vehicles equipped with ABS, since special tools are required to properly bleed such brakes. Take the vehicle to a service shop or other repair shop that has the necessary tools.

Withdrawal

1. Disconnect the wire from the negative battery terminal.

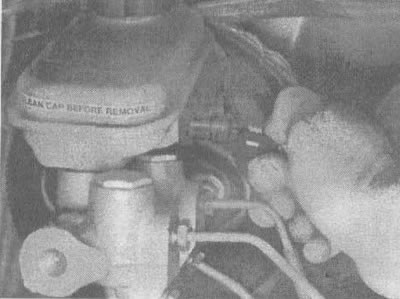

2. Disconnect the connector from the brake fluid level sensor (see illustration).

7.2. Disconnect the brake fluid level sensor connector

3. Place rags under the pipe fittings and prepare covers or plastic plugs to plug the ends of the pipes after they have been disconnected.

Attention! Brake fluid can damage paintwork. During work, cover all painted parts and be careful not to spill brake fluid.

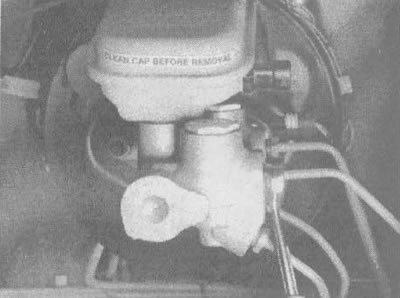

4. Loosen fittings (couplings) at the ends of the brake fluid lines where they enter the brake master cylinder (see illustration). To avoid stripping the edges, use a box wrench that wraps around the hex.

7.4. Disconnect the brake fluid lines using a box wrench

5. Pull the brake lines away from the master cylinder and plug their outlets to prevent contamination.

6. Turn away two nuts and remove the main brake cylinder from the car.

7. Remove reservoir cap and diaphragm, then drain any remaining fluid.

Repair

8. Clamp the main brake cylinder in a vise. Be sure to line the jaws of the vise with rags or wooden blocks so as not to damage the brake cylinder body.

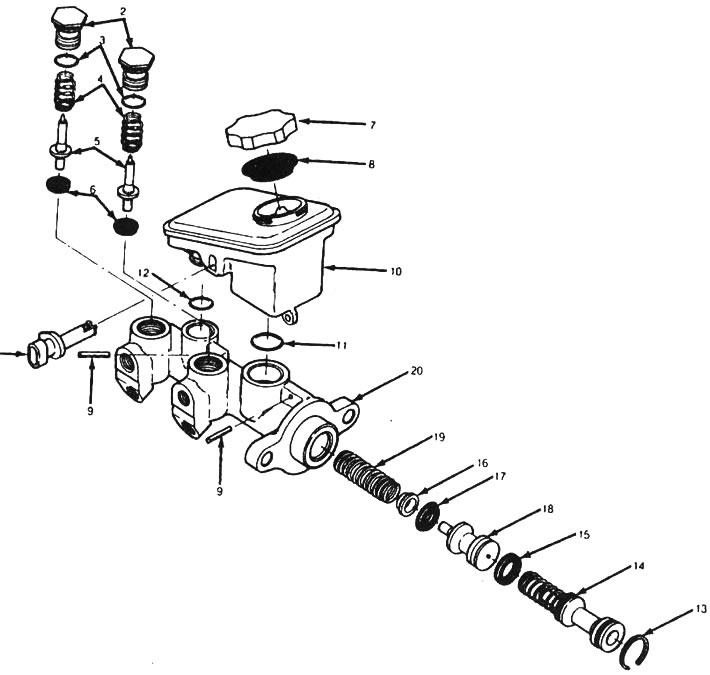

9. Remove pins (see illustration) 1/8 inch punch. Pull them up and separate from the brake master cylinder housing. Remove two o-rings.

7.9. Brake Master Cylinder Details: 1 - brake fluid level sensor, 2 - pressure relief valve plugs, 3 - sealing ring, 4 - spring, 5 - valve piston, 6 - valve cuff, 7 - reservoir cap, 8 - diaphragm, 9 - pin, 10 - reservoir, 11 - o-ring, 12 - o-ring, 13 - retaining ring, 14 - primary piston, 15 - cuff, 16 - spring plate, 17 - cuff, 18 secondary piston, 19 - spring, 20 - brake master cylinder housing

10. Remove the pressure relief valve plugs (see illustration 7.9). Remove o-rings, springs, pistons and valve seals. Be careful not to scratch or otherwise damage the stems or bores. Set aside each valve separately.

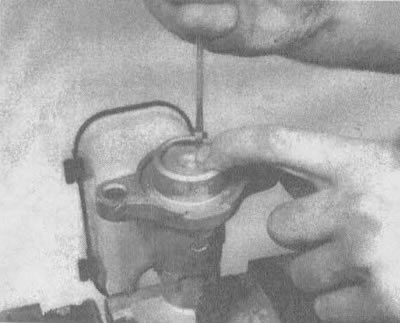

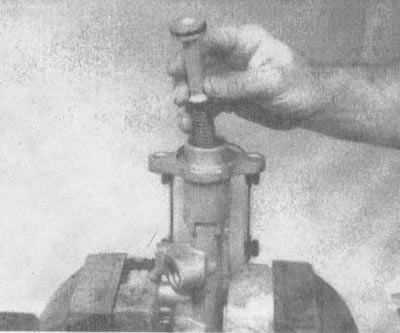

11. Remove the primary piston circlip by pressing on the piston and prying off the circlip with a screwdriver (see illustration).

7.11. Press the piston down and remove the primary piston circlip

12. Remove the primary piston (see illustration).

7.12. Remove the primary piston

13. Remove the secondary piston. It may be necessary to remove the brake master cylinder by gently tapping it with a piece of wood to expose the piston.

14. Clean the brake master cylinder body, primary and secondary pistons, pressure limiter valves and reservoir with brake cleaner or denatured alcohol and dry them with compressed air.

Attention! Do not, under any circumstances, use petroleum-based solvents to clean brake parts (gasoline, kerosene, etc)!

15. Check up, whether there are no traces of corrosion, scratches or furrows in an opening of the piston of the main brake cylinder. If there are any noticeable signs of corrosion or damage, replace the brake master cylinder body - do not attempt to use abrasives in an attempt to clear the hole.

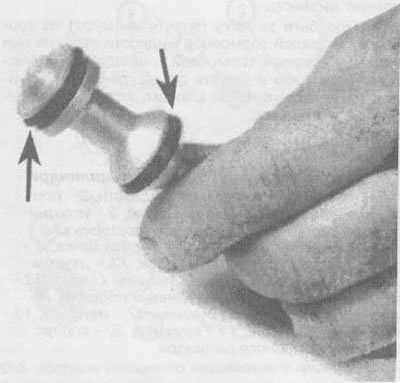

16. Remove the old cuff from the secondary piston and install a new one so that its edges are directed outward (see illustration).

7.16. The secondary piston cuffs should be installed so that their edges are directed, as shown in the photo

17. Install the spring cup to the secondary piston.

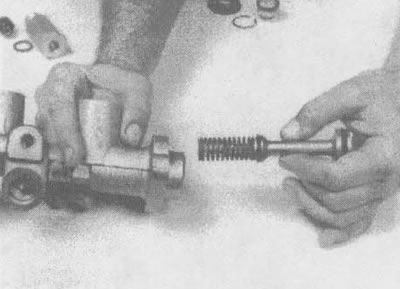

18. Lubricate the cylinder with clean brake fluid and install the spring and secondary piston (see illustration).

7.18. Insert secondary piston

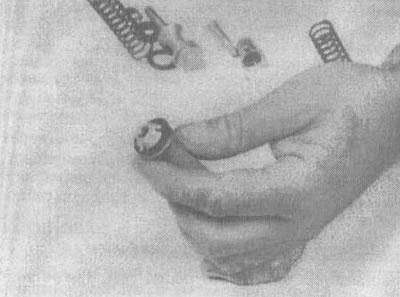

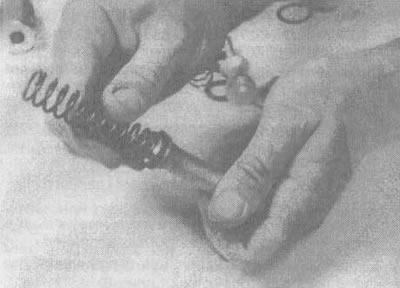

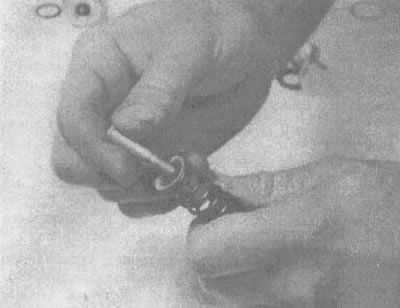

19. Disassemble the primary piston, paying attention to the location of the parts, then lubricate the seals with clean brake fluid and install them on the piston (see illustration).

7.19a. The primary piston collar must be installed so that the edges are directed away from the piston |

7.19b. Install seal protection over seal |

7.19c. Install the primary piston spring |

7.19 Place the spring plate on the spring |

7.19d. Insert the spring bolt through the plate and spring and screw it into the piston |

7.19e. Lubricate the O-ring with clean brake fluid, then slide it onto the piston |

20. Insert the primary piston into the cylinder (see illustration), push it in and install the retaining ring.

7.20. Insert the primary piston into the cylinder

21. Check the pressure relief valves for corrosion, scratches and gouges. Replace valves if necessary.

22. Lubricate the new o-rings and valve seals with the silicone grease included in the repair kit. Also lubricate the valve piston rods.

23. Fit new seals to the pressure relief valve pistons so that the edges of the seals point towards the plug.

24. Insert the distribution and seal valve pistons into the brake master cylinder housing.

25. Establish springs in the case of the main brake cylinder.

26. Install new o-rings in the appropriate grooves in the valve plugs.

27. Insert the pressure relief valve plugs into the brake master cylinder and tighten them to the torque specified in the specifications of this chapter.

28. Check up, whether on a tank of cracks and signs of deformation. If any damage is noticed, replace the reservoir.

29. Lubricate the new o-rings of the reservoir with clean brake fluid and insert them into the appropriate grooves in the master cylinder housing. Make sure they sit in the grooves.

30. Lubricate the reservoir pipes with clean brake fluid and install the reservoir on the main brake cylinder body by pressing it down.

31. Insert new studs fixing the tank. Be careful not to damage the reservoir or master cylinder housing.

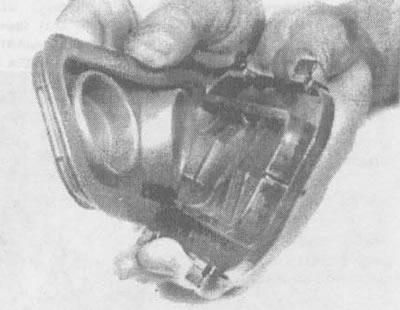

32. Check the reservoir diaphragm and plug for cracks and deformation. Replace any damaged parts with new ones and attach the diaphragm to the cover (see illustration).

7.32. Install a diaphragm

Note. When removing the master brake cylinder, every time it is necessary to carry out a complete pumping of the hydraulic system. You can reduce the time it takes to bleed the system by filling the brake master cylinder with brake fluid and bleed it on a workbench (see paragraphs. 33-36) before installing it on the car.

33. Insert plugs with a thread of the required size into the outlet holes of the brake lines and fill in the tanks with brake fluid. It is necessary to support the brake cylinder so that the brake fluid does not spill during the bleeding procedure on the workbench.

34. Loosen the plugs one at a time and push the piston assembly into the barrel so as to expel air from the brake master cylinder. To prevent air from being drawn back into the cylinder, the appropriate plug must be replaced before the piston is allowed to return to its original position.

35. Make 3-4 strokes with the piston on each outlet to ensure that all air trapped in the cylinder is removed.

36. Because the bench bleeding procedure does not involve the use of high pressure, there is an alternative to removing and installing plugs on each piston pass. Remove one of the plugs completely before pushing the piston in. Before releasing the piston, instead of reinstalling the plug, cover the hole tightly with your finger to prevent air from getting back into the brake master cylinder. Wait a few seconds for the brake fluid to be drawn from the reservoir into the piston barrel, then repeat the procedure. When you push down on the piston, it will push your finger out of the hole, allowing air to escape. When only brake fluid comes out of the hole, reinstall the plug and continue bleeding at the other hole.

37. Pour brake fluid into the master cylinder reservoirs and install the diaphragm and plug. Note. To prevent overfilling when installing the cup cap, fill only to the top of the cup divider.

Installation

38. Carefully install the master cylinder by reversing the disassembly procedure, fill the reservoir with the recommended type of brake fluid (see chapter 1, section 4), then bleed the brakes at the master cylinder and at each wheel (see section 9).