Examination

1. Loosen the wheel nuts, raise the vehicle and secure it on stands. Remove the wheel and tighten the three wheel nuts (flat side to disc), to hold the drive in place.

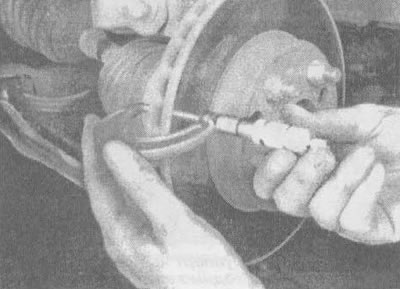

2. Remove the brake caliper as described in section 3. It is not necessary to disconnect the brake hose. After loosening the caliper bolts, hang the caliper on the wire (see illustration).

4.2. Hang the caliper on a wire whenever you need to change its position (do not leave it hanging on the brake hose!)

3. Inspect the disc surface for scratches, gouges or other damage. The presence of small scratches and small grooves can be considered normal and does not always significantly affect the performance of the brakes, however, deep grooves (over 0.015" deep (0.38mm)), require the removal of the disc and its regrinding in the workshop. Don't forget to check both sides of the disc (see illustration). If you notice pulsations when you apply the brakes, this may indicate disc beating.

4.3. The brake pads on this car are completely worn out; there are deep grooves in the disc - the wear is so great that the disc needs to be replaced

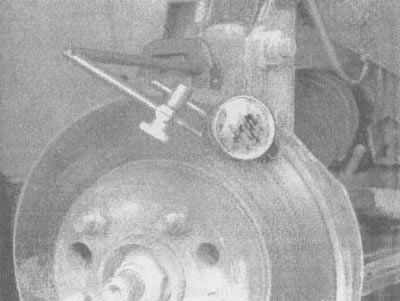

4. To check for disc runout, place the indicator at a point approximately 1/2" from the outer edge of the disc (see illustration). Set the indicator to zero and turn the dial. The indicator readings must not exceed the maximum allowable beat limit prescribed by the specifications. If this limit is exceeded, the disc must be reground in a workshop.

4.4a. Using an indicator, check for wear by setting the indicator needle approximately 1/2" from the outer edge

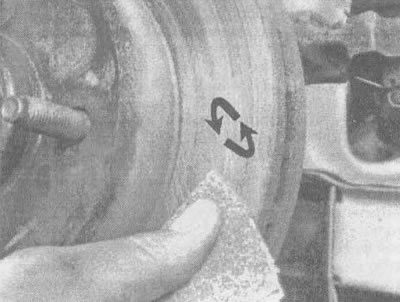

Note. It is recommended that re-grinding be done regardless of the gauge reading as this will give a smooth finish and ensure that there is no brake pedal pulsation or other disc related issues. If you decide not to refinish the discs, at least remove the polish ("glaze") from the surface with a medium-grained skin, processing in a circular motion (see illustration).

4.46. If you decide not to refinish the discs, at least remove the polish ("glaze") from surfaces with sandpaper

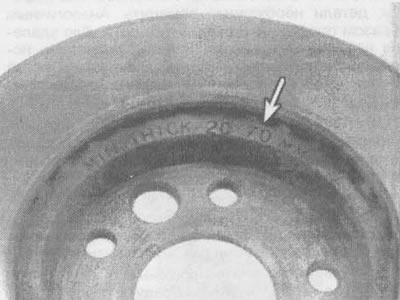

5. It is absolutely unacceptable to grind the disc when its thickness is below the permissible limit. The minimum thickness at which the disc must be replaced is molded on the inside of the disc (see illustration). It should not be confused with the minimum thickness at which a disc can be reground. Disc thickness can be checked with a micrometer (see illustration).

4.5a. Thickness at which disc needs to be replaced (arrow), molded on the inside of the disc |

4.5b. Measure the disc thickness with a micrometer |

Withdrawal

6. Remove the wheel nuts that were tightened to hold the disc in place and remove the disc from the hub.

Installation

7. Position disc over studs.

8. Install the caliper and brake pads on the disc and place on the steering knuckle (see section 3, for a description of the caliper installation procedure). Tighten the caliper bolts to the torque specified in the specifications in this chapter.

9. Install the wheel, then lower the vehicle to the ground. Depress the brake pedal several times to bring the brake pads into contact with the disc. If the brake fluid hose was not disconnected from the caliper, then there is no need to bleed the system. Before using the car in normal mode, carefully check the operation of the brakes.