Attention! Brake pads should be changed on both rear wheels at the same time - never change pads on just one wheel! Also, remember that the dust generated in the brake system may contain asbestos, which is hazardous to health. Never blow it out with compressed air or inhale it. When servicing the brake system, a protective filter mask must be worn. Do not, under any circumstances, use petroleum-based solvents to clean brake parts (kerosene and gasoline). Use only brake cleaner or denatured alcohol.

Attention! Every time the brake pads are replaced, the tension and retaining springs must be replaced. Because these springs are constantly subjected to cycles of heating and cooling, they lose their elasticity over time and can allow the pads to be attracted to the drums, causing wear on the pads that is much higher than normal. When replacing rear brake pads, use only high quality original spare parts.

1. Loosen the wheel nuts, raise the vehicle and secure it on stands.

2. Put the car on the parking brake.

3. Remove the wheel.

Note. It is necessary to replace all four brake pads of the rear wheels at the same time, but in order not to mix up the parts, work on each brake assembly in turn.

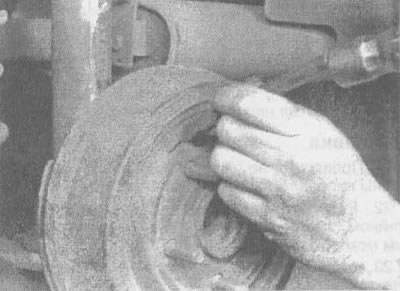

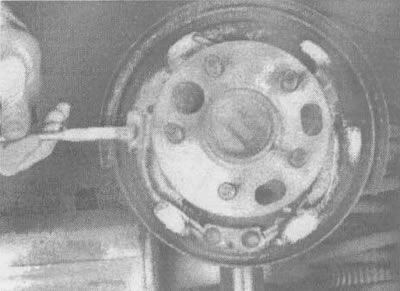

4. Check the condition of the pads and replace if necessary (see illustrations 5.4a-5.4e). Note. If the brake drum cannot be pulled off the axle shaft, check that the parking brake is fully released, then pour (squirt) some penetrating agent through the center of the hub. Let the agent soak in and try to pull the drum off again. If the drum still does not retract, the brake pads will have to be brought together. To do this, first remove the protrusion on the brake drum with a chisel and a hammer (see illustration 5.4a). When the tab is removed, pry the lever off the wheel adjusting screw with a small screwdriver while turning the adjusting wheel with another small screwdriver and moving the shoes away from the drum. Now the drum can be pulled off. The drum needs to be replaced.

5.4a. If the brake drum cannot be removed, it may be necessary to remove the protruding contour using a machinist's chisel and hammer (on some vehicles it has to be drilled out with a 7/16" drill), then turn the adjusting screw to move the brake pads away from the drum |

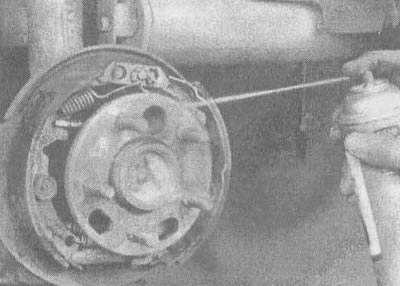

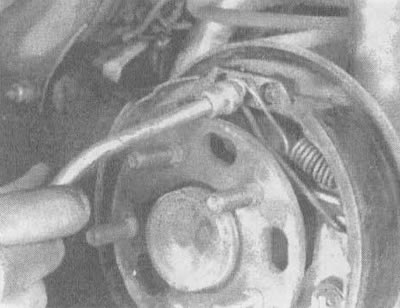

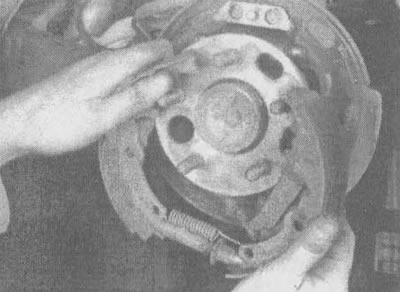

5.4b. Before removing anything, clean the brakes with brake cleaner or denatured alcohol; do not use compressed air to blow dust out of the brake assembly! |

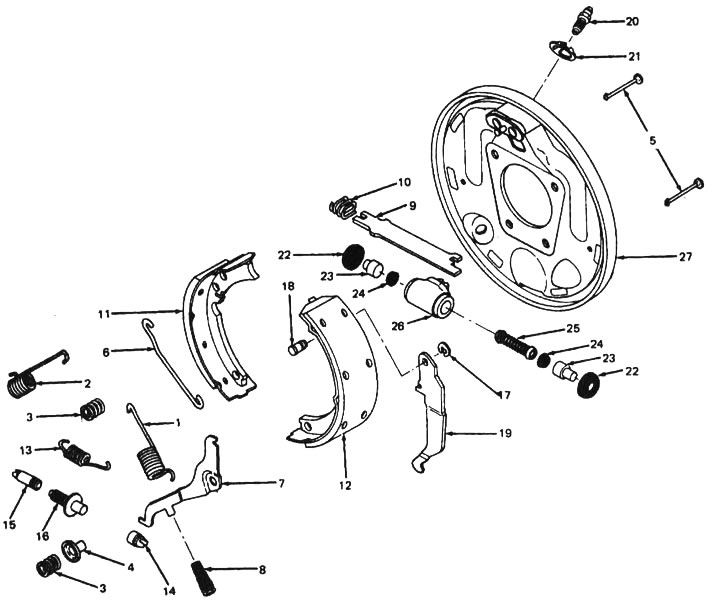

5.4c. Details of the drum brake system (cars produced in 1990 and 1991): 1 - return spring, 2 - return spring, 3 - retaining spring, 4 - lever axis, 5 - retaining pin, 6 - limiter, 7 - drive lever, 8 - lever return spring, 9 - spacer bar, 10 - bar spring, 11 - primary shoe, 12 - secondary shoe, 13 - adjusting screw spring, 14 - head, 15 - sleeve, 16 - adjusting screw, 17 - retaining ring, 18 - stud, 19 - parking brake lever, 20 - bleed valve, 21 - cylinder retainer, 22 - protective cover, 23 - piston, 24 - cuff, 25 - spring, 26 - working brake cylinder, 27 - brake shield

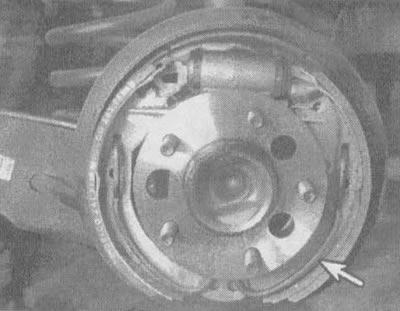

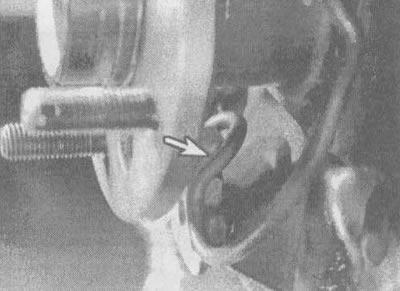

5.4g 1992 and later vehicles have one cone spring (arrow) |

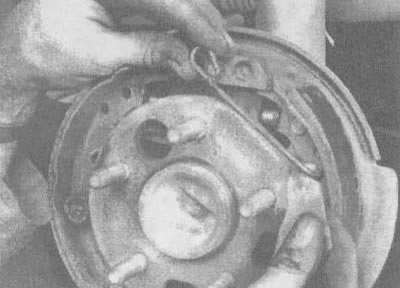

5.4d. Using the brake spring removal tool, remove the return springs (for cars manufactured in 1990 and 1991) |

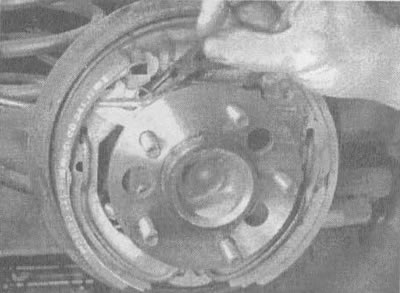

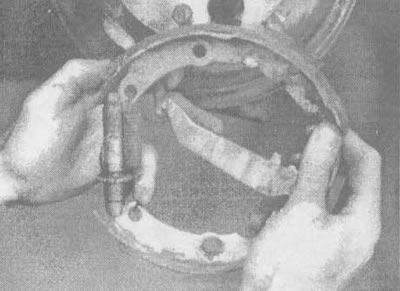

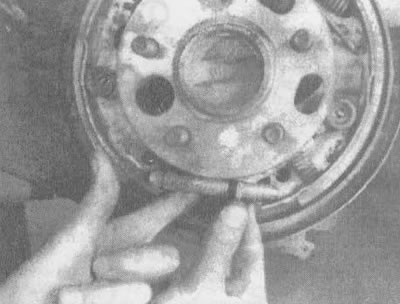

5.4f. Using small pliers, remove the retaining springs and pins by pushing and turning them (indicated by arrows) (cars produced in 1990 and 1991) |

5.4g. Remove the retainers (clamping) springs and studs by pressing with pliers and turning (indicated by an arrow) (cars produced in 1990 and 1991) |

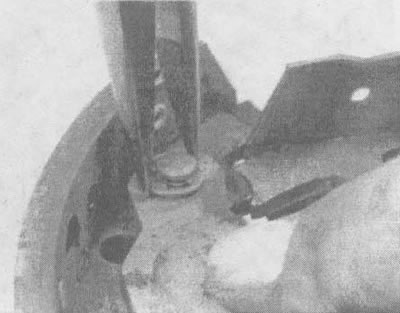

5.4z. Insert a flathead screwdriver under the spring and push the spring out of the primary shoe, then remove the shoe (cars produced in 1992) |

5.4i. Pull up the parking brake lever (cars produced in 1990 and 1991) and remove it from the axle along with the return spring (indicated by arrows) |

5.4k. Remove the brace (for all models). On cars manufactured in 1992, also unscrew the adjusting screw, remembering the direction in which it is installed |

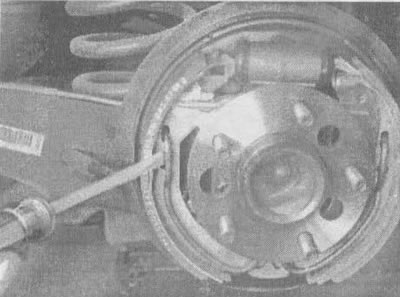

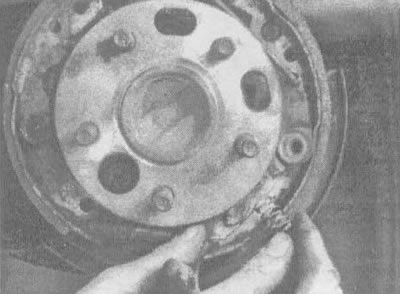

5.4l. After stretching the pads to free the hub flange, remove it from the brake shield (for cars 1990 and 1991 release) |

5.4m. On 1992 vehicles, lift the spring off the rear brake shoe and unscrew the shoe from the hub area to access the parking brake cable |

5.4n. Disconnect the parking brake lever from the cable and remove the shoes (cars produced in 1990 and 1991) |

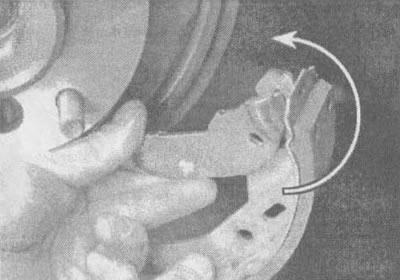

5.4o. On 1992 vehicles, turn the brake shoe to release the parking brake lever from the shoe |

5.4p. On vehicles manufactured since 1992, using a screwdriver, remove the return spring (arrow). When installing new pads on these vehicles, first perform the operations of paragraphs 5.4y and 5.4f, then remove the removal points in reverse order and proceed to paragraph 5.4d |

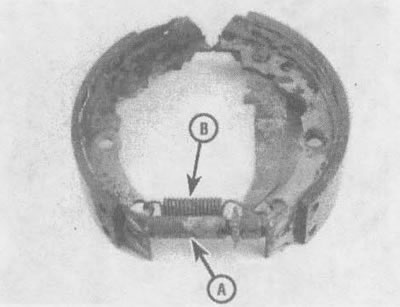

5.4r. Loosen the adjusting screw (A) and remove the spring (IN) from the pads, pay attention to the position in which they are installed (cars produced in 1990 and 1991) |

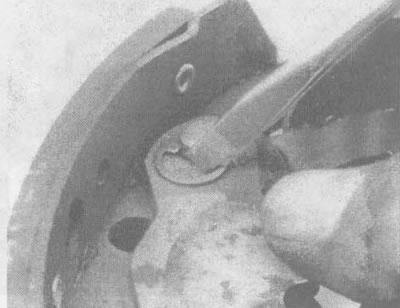

5.4s. On cars manufactured in 1990 and 1991. remove the parking brake lever by unhooking the C-clip |

5.4t. Install the parking brake lever on the new brake pad and slide the C-clip into place (cars produced in 1990 and 1991) |

5.4y. Lubricate the contact surfaces of the brake shield with white lithium-based grease (cars of all models) |

5.4f. Lubricate the adjusting screw with white lithium based grease before screwing it in (all models) |

5.4x. Connect the parking brake lever to the cable (cars produced in 1990 and 1991) |

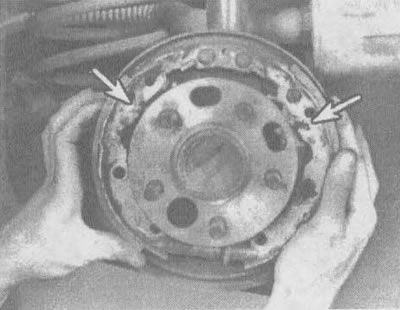

5.4c. Stretch the pads so that the hub flange passes through them, and insert the pads into place (cars produced in 1990 and 1991) |

5.4h Insert parking brake bar and spring (cars produced in 1990 and 1991) |

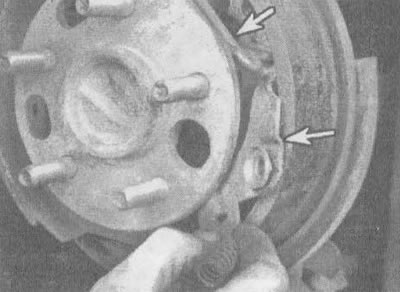

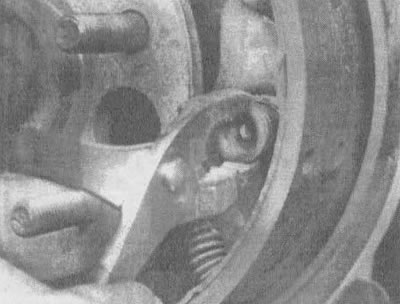

5.4sh. Check if the parking brake bar is correctly positioned in the shoes (indicated by arrows) |

5.4s. Install the retaining pin and spring on the primary brake shoe (cars produced in 1990 and 1991) |

5.4th. Install the limiter and lever on the secondary brake shoe (cars produced in 1990 and 1991) |

5.4aa. Insert lever return spring (cars produced in 1990 and 1991) |

5.4ab. Screw the retaining pin and spring into the secondary brake shoe (cars produced in 1990 and 1991) |

5.4av. Put on return springs (cars produced in 1990 and 1991) |

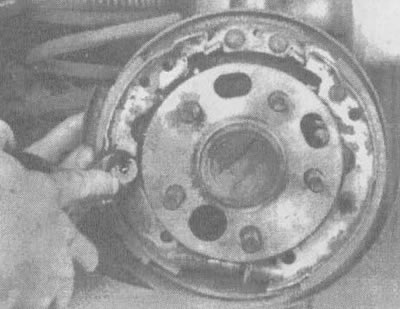

5.4ag. Center the brake pads so that the drum slides over them (for all models) |

5.4ad. Adjust the adjusting nut so that the drum slides onto the shoes with little effort (for all models) |

5.4ae. Clear polished ("glazed") sections from the surface of the brake drum with fine-grained sandpaper, having processed the surface in a circular motion

5. Before installing the drum in its original place, check for cracks, nicks, deep grooves and hard spots, which appear as small discolored areas. If such areas cannot be removed with sandpaper or any other of the above violations are observed, the drum will have to be taken to the workshop.

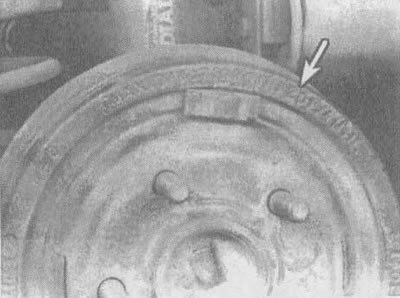

Note. It is recommended that drums be resurfaced, regardless of their surface appearance, as this will produce a perfectly round drum and eliminate any brake pedal pulsation or other irregularities associated with a defective brake drum. If you decide not to refinish the drums, at least remove the polish ("glaze") from the surface with a medium-grained sandpaper, working the drum in a circular motion. Disc diameter at maximum wear is molded on each brake drum (see illustration).

5.5. The maximum allowable diameter is molded on the drum (indicated by an arrow), which is the size of the wear limit, and not the size at which regrinding is still acceptable

6. Install the brake drum on the axle flange.

7. Put on the wheel, tighten the wheel nuts, then lower the car. Tighten the nuts to the torque specified in the specifications in this chapter.

8. Do several forward and reverse braking to adjust the brakes until you achieve satisfactory pedal action when braking.