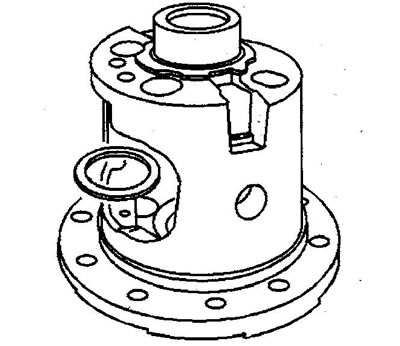

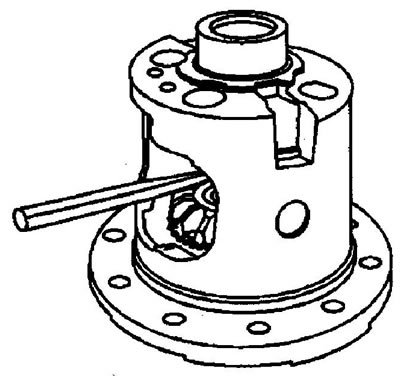

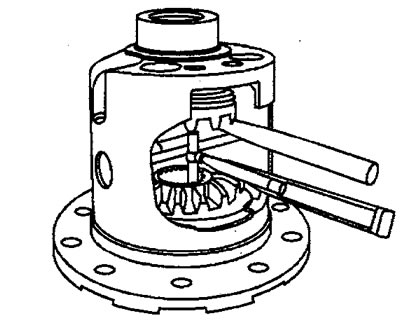

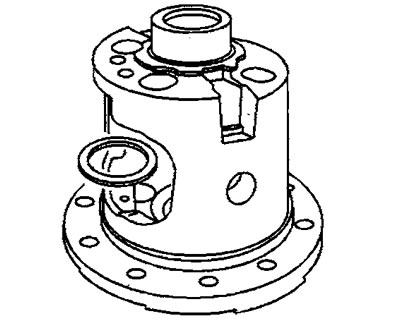

Cup disassembly

Gearboxes 8.6" and 9.5"

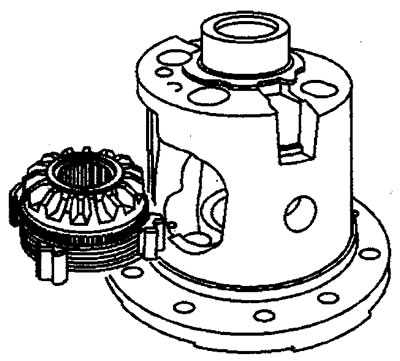

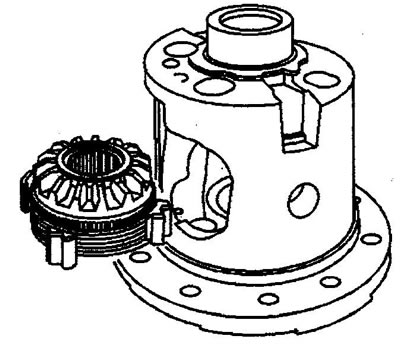

1. Remove the driven gear of the reducer.

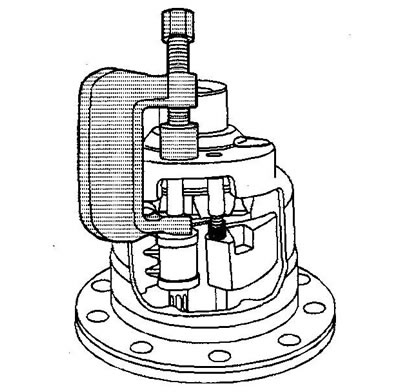

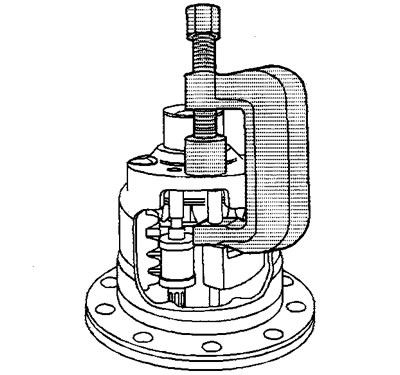

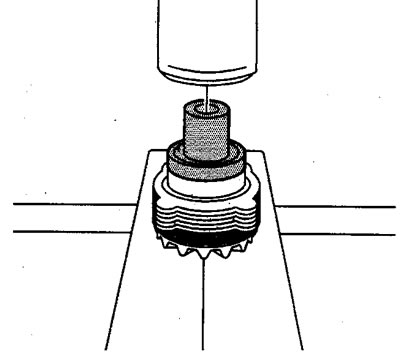

2. Use a clamp to remove the regulator bushing.

3. Remove the regulator assembly. To facilitate adjuster removal, rotate the side gear so that the adjuster fits between the two teeth of the side gear.

4. Use a clamp to remove the latch bracket bushing. Remove the bracket. To facilitate removal of the bracket, turn the side gear so that the bracket fits between the two teeth of the side gear.

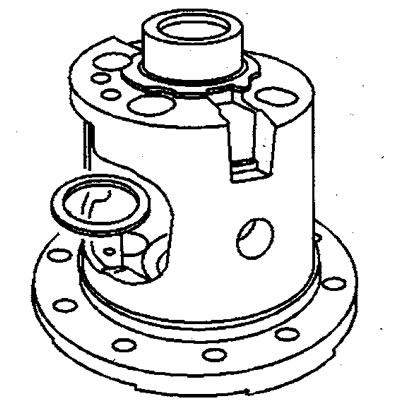

5. Remove the bolt fixing the axis of the drive gears.

6. Remove the drive gear shaft.

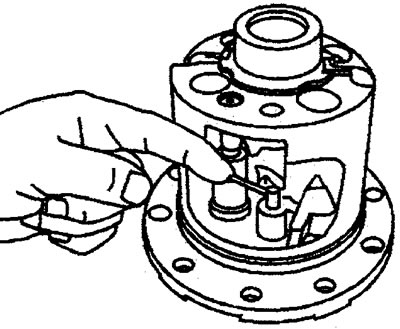

7. Remove drive gears and thrust washers through differential cup windows. Mark the gears and thrust washers for proper alignment during reassembly.

8. Remove the thrust block.

9. Remove the right side side gear and clutch disc assembly.

10. Remove the right side shim.

11. Remove the left side gear and clutch disc assembly.

12. Remove the left side gear thrust washer.

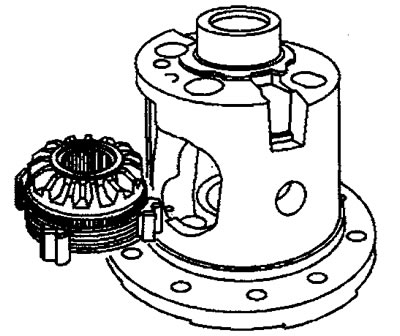

Clutch disassembly

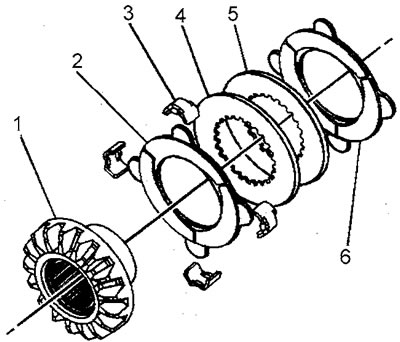

Reducer 8.6" - Right side

1. Remove the guides (3).

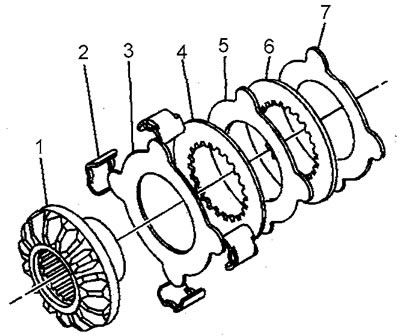

Reducer 9.5" - Right side

1. Remove the guides (2).

2. Remove from side gear (1) driven and driven clutch discs (2), (3), (4), (5), (6) And (7).

Reducer 8.6" and 9.5" - left-hand side

1. Measure and record the total length of the left side gear assembly from the end of the gear to the thrust bushing, including the side gear thrust washer.

2. Remove the clutch disc guides.

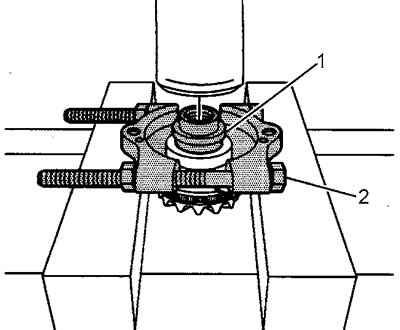

3. Reducer 9.5": using a bearing puller (2), mandrels (1) and press, remove the thrust bushing from the gear.

Reducer 8.6": remove the lock washer.

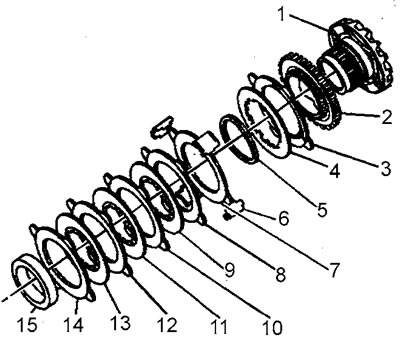

4. Disassemble the left side gear assembly:

- A) Remove driven and driven clutch discs (7-14).

- b) Remove spring washer (5).

- V) Remove pressure plate (4).

- G) Remove disc (3) with carbon coating.

- d) Remove the cam (2) from side gear (1).

Caution: Do not replace the thrust bushing unless necessary.

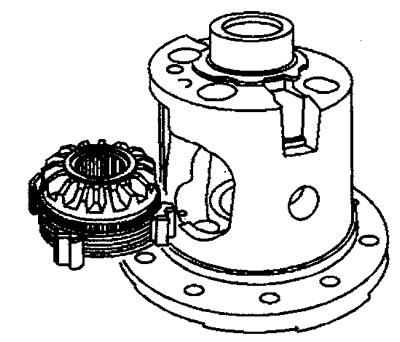

Disassembly of the side gear assembly

Clutch Assembly

Reducer 8.6" and 9.5" - left-hand side

1. Lubricate all discs with gear oil.

2. Assemble the clutch in the order shown in the illustration in section "Disassembly" until the retaining ring or thrust sleeve is installed.

Reducer 8.6"

3. Install retaining ring (15).

4. Align the tabs on the disc (3) with cam grooves (2), compress the clutch disc assembly and install the circlip (15).

5. Install the guides (6). Apply grease to the guides to hold them in place.

Reducer 9.5"

3. Align the tabs on the disc (3) with cam grooves (2). Install thrust bushing (15) to the side gear.

4. Using a mandrel and a press, press the thrust onto the side gear.

5. If the side gear or thrust bushing has been replaced, measure the overall length of the gear:

- A) Install the clutch disc thrust washer onto the thrust bushing.

- b) Measure the total length of the assembly from the end of the gear to the thrust washer.

- V) Compare the result obtained with the value obtained during disassembly.

- G) If the new length differs from the old one by±0.762 mm (0.003 in), select a new thrust washer with a thickness as close as possible to the old overall assembly length.

6. Align the ears of all driven clutch discs.

7. Install guides (6). Apply grease to the guides to hold them in place.

Reducer 8.6" and 9.5" - Right side

Assembly is carried out in the reverse order of disassembly. Apply grease to the guides to hold them in place.

Adjustment of the blocked differential

Attention: if it was necessary to replace the left or right side gear assembly or thrust block, after replacement, the differential must be adjusted. Adjustment of gaps in the engagement is carried out by replacing the shims of the clutch disc and / or selecting a thrust block. Keep in mind that proper clearance selection is critical to proper differential operation.

Left side gear clearance

1. Install the left side gear shim into the differential cup.

2. Install the left side gear assembly into the differential cup.

3. Install the drive gears and their thrust washers into the differential cup. Align the holes in the gears, thrust washers and cups for installing the gear axle.

4. Install the gear shaft. It may be necessary to press down on the left side gear assembly to install the axle. If, even after the gear assembly has settled, the axle cannot be installed, install a thinner thrust washer under the gear.

5. Install the axle fixing bolt, hand-tighten the bolt.

6. Rotate the drive gear closest to the axle fixing bolt so that one tooth is pointing down, perpendicular to the reducer driven gear flange.

7. Install the copper pin between the side gear and the drive gear shaft. Press the end of the pin until the clutch discs are compressed.

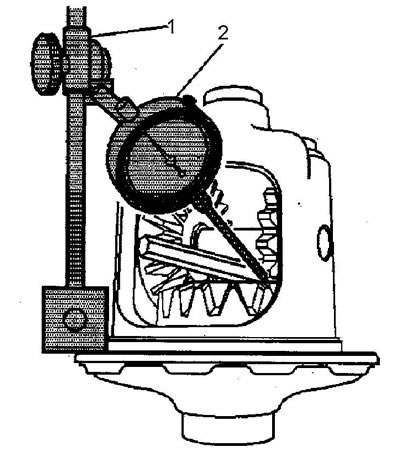

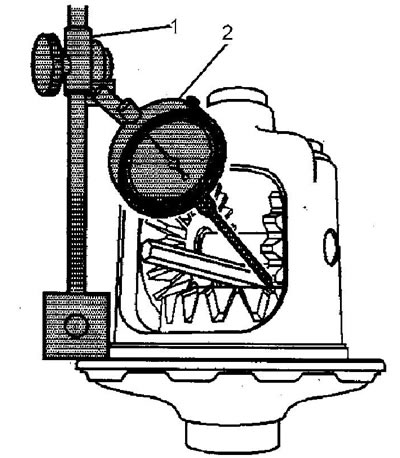

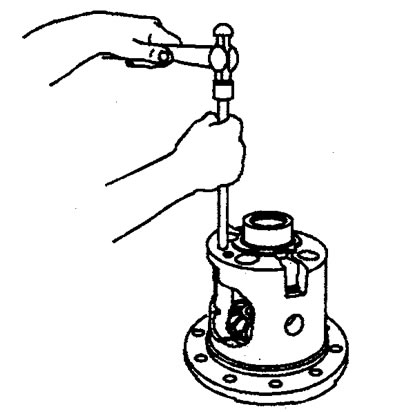

8. Measure the engagement clearance as follows:

- A) Install the magnetic stand (1) on the flange of the driven gear of the reducer.

- b) Mount the dial indicator on the rack (2).

- V) Install the indicator foot onto one of the differential drive gear teeth closest to the gear axle fixing bolt. Set the indicator to zero.

- G) Press the drive gear against the differential cup.

- d) Rotate the drive gear from stop to stop and determine the amount of clearance in the engagement.

Gap in engagement:

- reducer 8.6" - 0.25-0.40 mm

- reducer 9.5" - 0.28-0.42 mm

9. If the clearance is too large, install a thicker clutch disc thrust washer; if too small, install a thinner washer. Washers are available in sizes from 0.6 to 1.32 mm with progressively increasing pitch.

Clearance of the right side gear

1. If necessary, remove the drive gear axle fixing bolt, drive gear axle, drive gears with thrust washers, left side gear assembly.

2. Install the right side gear shim into the differential cup.

3. Install the right side gear into the differential cup.

4. Install differential drive gears with their thrust washers. Align the holes of the gears and thrust washers with the holes in the cup for installing the gear axle.

5. Using a copper pin, compress the right gear clutch pack and install the drive gear axle. If the axle cannot be installed, install a thinner side gear shim.

6. Install the gear axle fixing bolt, hand tighten the bolt.

7. Rotate the drive gear so that one tooth is pointing down, perpendicular to the reducer driven gear flange.

8. Install the copper pin between the side gear and the drive gear shaft. Press the end of the pin until the clutch discs are compressed.

9. Measure the engagement clearance as follows:

- A) Install the magnetic stand (1) on the flange of the driven gear of the reducer.

- b) Mount the dial indicator on the rack (2).

- V) Install the indicator foot onto one of the differential drive gear teeth closest to the gear axle fixing bolt. Set the indicator to zero.

- G) Press the drive gear against the differential cup.

- d) Rotate the drive gear from stop to stop and determine the amount of clearance in the engagement.

Gap in engagement:

- reducer 8.6" - 0.076-0.23 mm

- reducer 9.5" - 0.051-0.203 mm

10. If the gap is too large, install a thicker thrust washer of the clutch disc; if it is too small, install a thinner washer. Washers are available in sizes from 0.25 to 1.50 mm in increments of 0.025 mm.

Thrust Block Clearance Adjustment

Attention: before adjusting the clearance of the thrust block, the clearance in the meshing of the right and left differential side gears must be adjusted.

1. Install the left side gear clutch disc thrust washer.

2. Install the left side gear assembly.

3. Install the right side gear thrust washer.

4. Install the right side gear assembly.

5. Install the drive gear axle.

6. Install the gear axle fixing bolt, hand tighten the bolt.

7. Install the copper pin between the end of the left side gear and the drive gear axle. Press the free end of the pin until the left gear clutch pack is fully compressed.

8. Install a copper pin between the end of the right side gear and the axis of the drive gears. Push the free end of the pin until the right gear clutch pack is fully compressed.

9. With telescopic gauge (25-50 mm) measure the distance between the ends (but not teeth!) side gears.

10. Remove the telescopic gauge.

11. Measure the distance between the ends of the gauge. Record the result.

12. Compare the result obtained with the dimensions of the available thrust blocks. Select the block whose height is equal to the distance between the gears (see point 11).

13. If none of the blocks are of equal size, choose the one with the nearest lower height. For example, if the distance between the gears is 33.833 mm, select a block with a height of 33.782 mm.

14. If the distance between the gears is less than 33.578 mm (reducer 8.6") or 40.488 mm (reducer 9.5"), install a thinner clutch disc thrust washer on the left and/or right.

Attention: after replacing the thrust or adjusting washer, the clearance in the engagement must be checked and, if necessary, adjusted.

15. If the distance between the gears is greater than 34.29 mm (reducer 8.6") or 41.12 mm (reducer 9.5"), install a thicker clutch disc thrust washer on the left and/or right.

Attention: after replacing the thrust washer, the clearance in the engagement must be checked and, if necessary, adjusted.

16. Recheck and, if necessary, adjust the clearances in the engagement of the side gears.

17. Recheck thrust block clearance, adjust if necessary.

18. Assemble the differential.

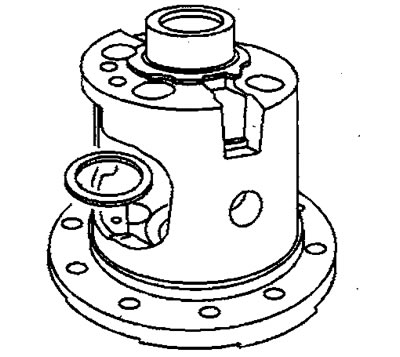

Differential Assembly

Attention: before assembling the differential, the procedure for adjusting all clearances must be carried out.

1. Install the left side gear clutch disc thrust washer.

2. Install the left side gear assembly.

3. Install the right side gear thrust washer.

4. Install the right side gear assembly.

Attention: if old gears and thrust washers are installed, install them in their original places.

5. Install the drive gears and their thrust washers.

6. Install thrust block. The open side of the block must face the differential cup window.

7. Install the drive gear axle.

8. Install a new pinion gear axle fixing bolt. Tighten the bolt by hand.

9. Install the regulator assembly.

10. Using a copper drift and a hammer, install the regulator fixing sleeve so that the axial movement of the regulator is in the range of 0.25-1.27 mm.

11. Install the locking bracket assembly. The straight end of the bracket spring should be above and outside the governor shaft.

12. Using a copper drift and a hammer, install the bracket fixing sleeve so that the axial movement of the bracket is in the range of 0.00-0.051 mm.

13. Tighten the pinion gear axle fixing bolt. Torque:

- reducer 8.6" - 36 Nm.

- reducer 9.5" - 50 Nm.

14. Install the reducer driven gear.