Withdrawal

1. Raise the car.

2. Drain the oil from the front axle gearbox.

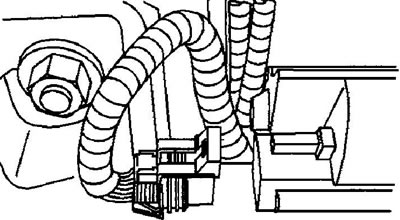

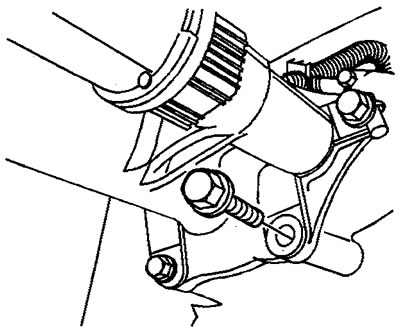

3. Disconnect the axle engagement drive wiring connector.

4. Release the axle engagement wires from the support clip on the axle beam.

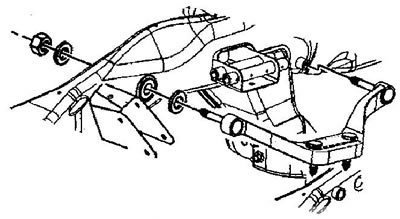

5. Remove the anti-roll bars (reducer 9.25") or shock absorber (reducer 8.25").

6. Turn away bolts of fastening of a power shaft of a wheel to an axle shaft of the bridge.

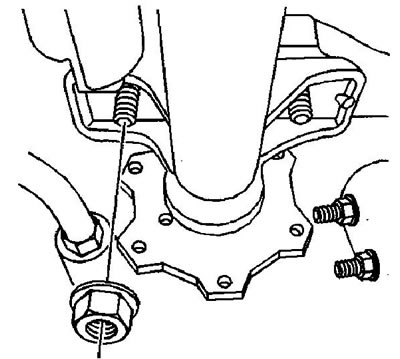

7. Turn away nuts of fastening of a beam of the bridge to an arm.

8. On 2500 and 3500 series models, complete the following steps to provide additional workspace:

- A) Loosen the nuts securing the front axle bracket to the frame.

- b) slide the front axle bracket towards the engine. It may be necessary to pull down on the axle beam and/or pull up on the bracket.

9. Turn away bolts of fastening of a beam of the bridge to a reducer case.

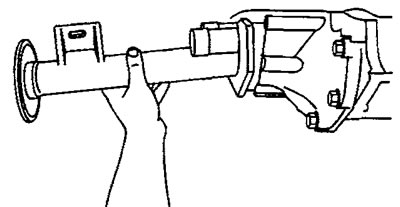

10. Carefully separate the axle beam from the differential housing.

Caution: Hold the open end of the bridge beam up.

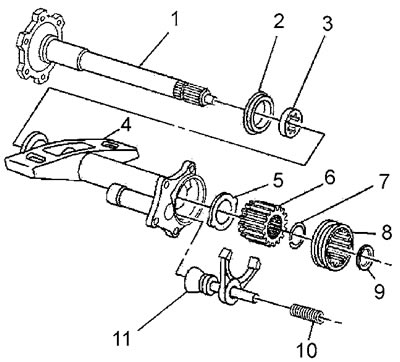

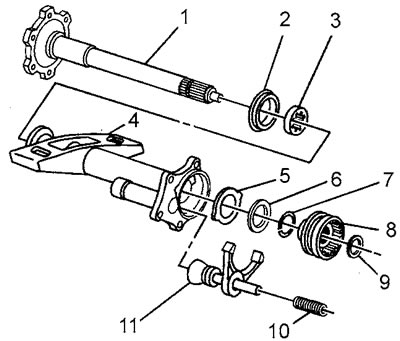

11. On models with 8.25 gear" remove the following parts from the bridge beam:

Early models

- A) inner spring (10) clutch forks.

- b) clutch fork (11).

- V) shim (9).

- G) Clutch (8).

- d) Clutch gear (6):

- clamp the bridge beam (4) in a vice for the mounting flange.

- by blowing a hammer with a soft metal head, knock out the axle shaft (1) from the gear (6), remove the gear.

- e) thrust washer (5).

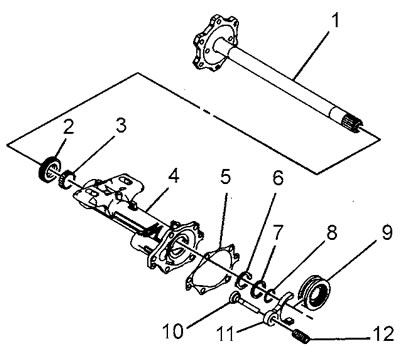

Later models

- A) inner spring (12).

- b) clutch fork (11).

- V) fork link (10).

- G) Clutch (9).

- d) Axle retaining ring (8).

- e) First thrust washer (7).

- and) Second thrust washer (6).

- h) Bridge beam laying (5).

12. On models with 9.25 gear" remove the following parts from the bridge beam:

- A) inner spring (10) clutch forks.

- b) clutch fork (11).

- V) shim (9).

- G) Clutch (8).

- d) Retaining ring (7).

- e) Thrust washers (5) And (6).

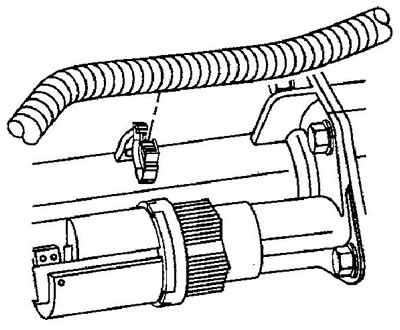

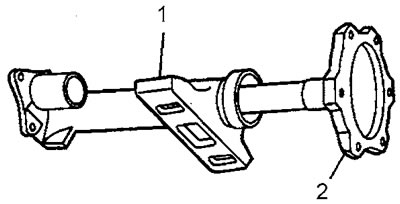

13. Remove from beam (1) axle shaft (2). If necessary, use a soft-faced hammer.

14. Remove the oil seal and axle bearing from the beam

Installation

1. Install a new bearing and axle shaft seal in the axle beam.

2. Install the axle shaft in the axle beam. If necessary, use a soft-faced hammer.

3. Place the axle shaft vertically on the wheel drive shaft connection flange.

4. On models with 8.25 gear" install the following parts:

Early models

- A) Thrust washer by aligning the tabs of the washer with the slots in the axle beam. Recommendation: Lubricate the thrust washer with grease to hold it in place.

- b) Lock washer in the clutch gear.

- V) Clutch gear on the axle shaft until the retaining ring snaps into place. If necessary, use a soft-faced hammer.

- d) Adjusting washer of the desired thickness.

- e) Clutch.

- and) Clutch fork.

- h) Clutch inner spring.

Later models

- A) Second thrust washer.

- b) First thrust washer.

- V) Half shaft retaining ring.

- G) Clutch.

- d) Fork pull.

- e) Clutch fork.

- and) Internal spring.

- h) Bridge beam laying.

5. On models with 9.25 gear" install the following parts:

- A) Thrust washer by aligning the tabs of the washer with the slots in the axle beam. Recommendation: Lubricate the thrust washer with grease to hold it in place.

- b) Second thrust washer.

- V) Retaining ring on the shaft.

- G) Adjusting washer of the desired thickness.

- d) Clutch.

- e) Clutch fork.

- and) Clutch inner spring.

6. Apply sealant to the axle beam flange or install a new gasket.

7. Install the axle beam assembly on the gear case.

8. Install and tighten the axle beam to gearbox bolts. Tightening torque: reducer 8.25" 55 Nm; reducer 9.25" 40 Nm.

9. On 1500 and 2500 series models:

- A) Move the front axle bracket to the frame. Install the front axle bracket studs into the axle shaft flange. It may be necessary to pull the bracket up and/or pull the axle beam down to allow clearance for the studs.

- b) Tighten the nuts securing the front axle bracket to the frame. Tightening torque 90 Nm.

10. Tighten the nuts securing the beam to the bracket. Tightening torque 100 Nm.

11. Connect the wheel drive shaft to the axle shaft flange. Tighten the mounting bolts. Tightening torque 80 Nm.

12. Install the stabilizer links or shock absorber.

13. Fasten the wires of the axle engagement drive to the axle beam.

14. Connect the wiring connector of the axle engagement drive.

15. Fill the gear housing with gear oil.

16. Lower the car.