Withdrawal

1. Before removing the valve body, make sure it is really necessary.

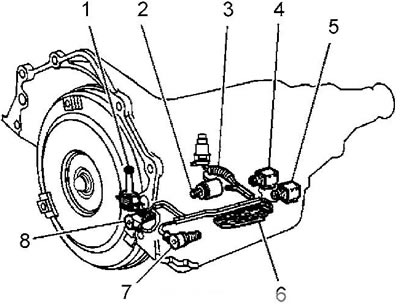

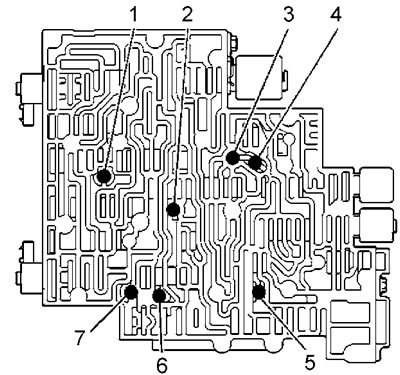

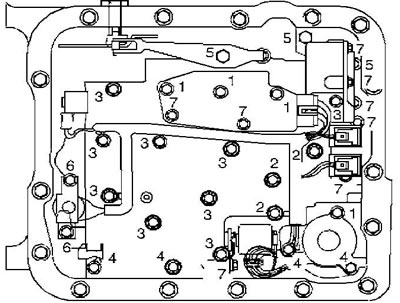

2. Without removing the valve body, you can replace:

- torque converter clutch valve (1);

- pressure control valve (2);

- internal wire harness (3);

- 2-3 shift valve (4);

- shift valve 1-2 gears (5);

- pressure regulator valve position sensor (6);

- 3-2 shift valve (7);

- torque converter clutch pulse width modulation valve (8).

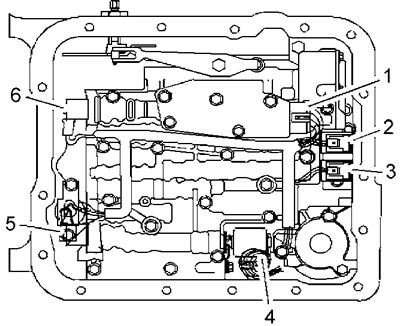

3. Disconnect the internal connectors:

- pressure regulator valve position sensor (1);

- shift valve 1-2 gears (2);

- shift valve 2-3 gears (3);

- pressure control valve (4);

- valve modulation pulse width clutch (5);

- shift valve 3-2 gears (6).

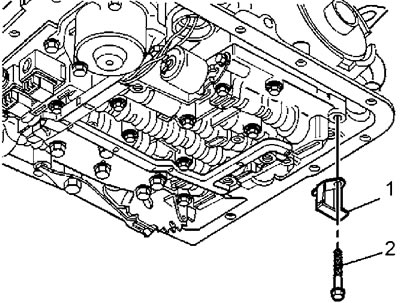

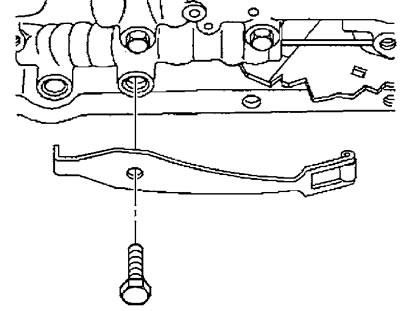

4. (Modifications) Remove the bolt (2) bracket for the limiter of the working fluid indicator.

5. Remove the fluid indicator restrictor bracket (1).

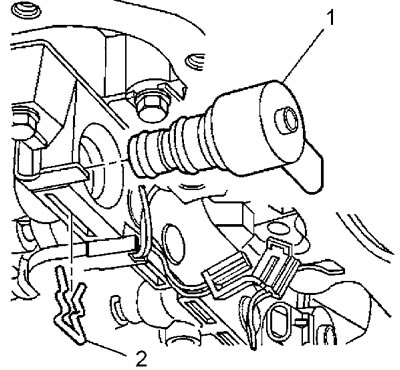

6. Use a small screwdriver to remove the retainer (2) valve (1) torque converter clutch pulse width modulation. Rotate the valve to fit if necessary to gain access to the retainer.

7. Remove valve (1) torque converter clutch pulse width modulation.

8. Turn away bolts of fastening of the valve of blocking of the coupling of the hydrotransformer.

9. Remove the torque converter clutch lock-up valve from the valve body (together with O-ring and wire harness).

10. Lay the wires aside.

11. Turn away bolts of fastening of the switch on pressure to the case of valves.

12. Remove the pressure switch.

13. Check the condition of the switch.

14. Turn away a bolt of fastening of a spring of a manual clamp.

15. Remove the detent spring.

16. Check the condition of the latch, look for cracks or damage.

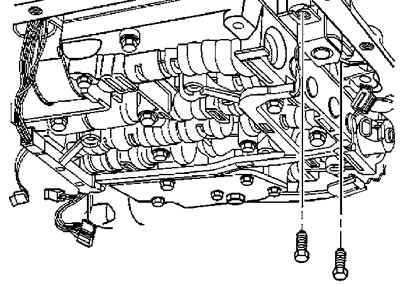

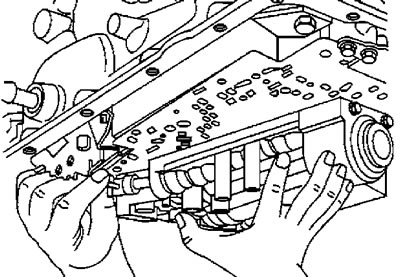

Caution: When removing the valve body, keep it horizontal to prevent loss of the check valve balls located in the valve body drill holes.

17. Turn away other bolts of fastening of the case of valves.

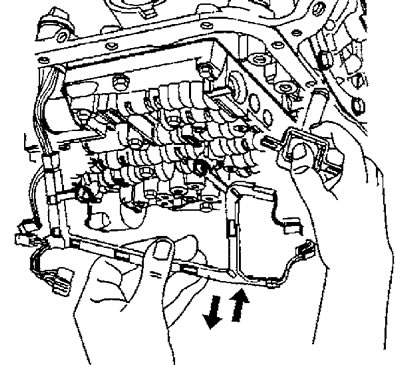

18. Carefully lower the valve body while disengaging the manual valve linkage.

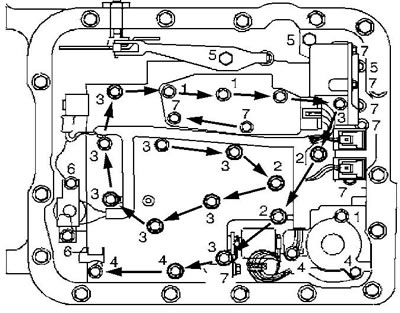

19. Remove 7 check valve balls.

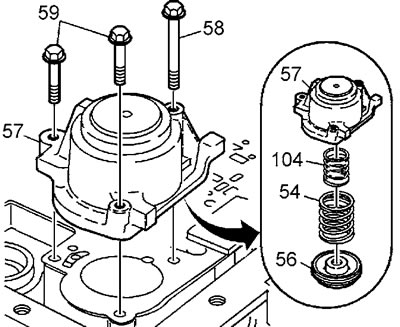

20. Loosen the bolts (58) And (59) lids (57) battery.

21. Remove the cover (57).

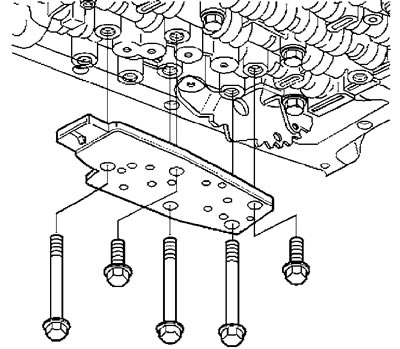

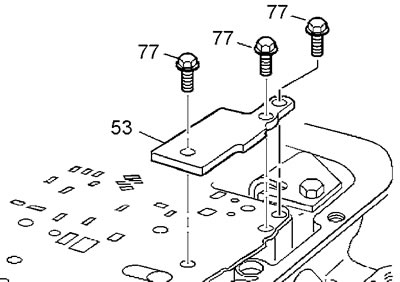

22. Remove the bolts (77) spacers.

23. Remove spacer (53).

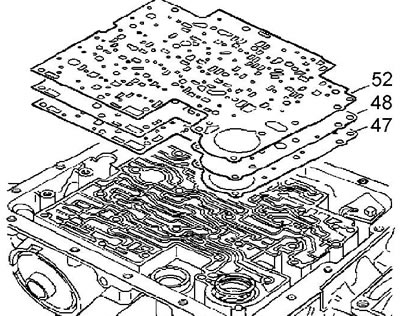

24. Remove the valve body gasket (52), spacer (48), and crankcase gasket (47).

Installation

1. Install a NEW valve body gasket (52), spacer (48) and a NEW crankcase gasket (47).

2. Install spacer (53) and bolts (77) spacer fasteners. Tighten the bolts. Tightening torque 10 Nm.

3. Install the battery cover assembly (57).

4. Install bolts (58) And (59). Tighten the bolts. Tightening torque 10 Nm.

5. Place seven check balls in the valve body.

6. Carefully install the valve body while connecting the manual valve rod.

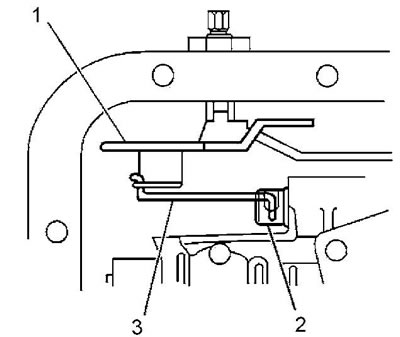

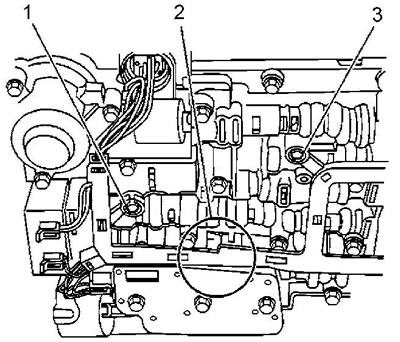

7. Make sure the traction (3) hand valve has engaged with the valve (2) and locking lever (1).

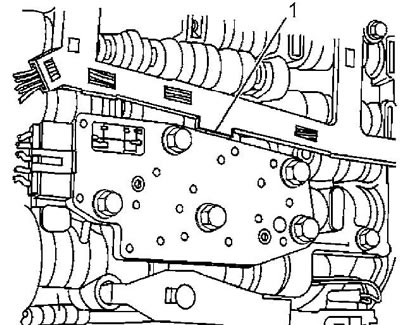

8. Install one bolt (M6x1 length 47.5 mm) into the center hole (1) valve body, finger-tighten the bolt.

Attention: since the sizes of the valve body mounting bolts are different, be careful when installing them.

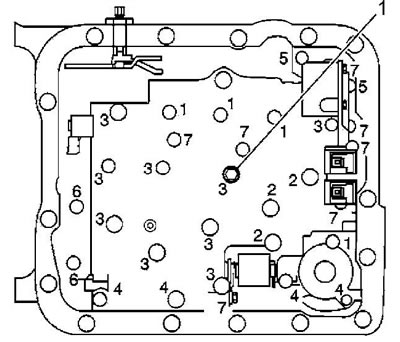

9. Install, but do not tighten, the valve body mounting bolts. The bolt locations are shown in the figure.

Locations for valve body mounting bolts. 1 - М6х1 - 65.0 mm, 2 - М6х1 - 54.4 mm, 3 - М6х1 - 47.5 mm, 4 - М6х1 - 35.0 mm, 5 - М8х1 - 20.0 mm, 6 - М6х1 - 12.0 mm, 7 - M6x1 - 18.0 mm.

Note: (modifications) do not install the fluid indicator restrictor bracket and its mounting bolt yet.

10. Install the manual detent spring.

11. Install the manual detent spring bolt.

12. Install a fluid pressure switch.

13. Tighten the switch mounting bolts by hand.

Note: the valve body bolts are tightened in order "spiral", starting from the center. A different tightening order may cause the valves to malfunction.

14. Tighten the valve body mounting bolts in order "spiral". Tightening torque 11 Nm.

15. Verify that the manual detent spring is properly seated on the detent lever. Tighten the mounting bolt. Tightening torque 11 Nm.

16. Install the torque converter clutch lock-up valve with a NEW O-ring to the valve body.

17. Install the blocking valve mounting bolts, tighten the bolts. Tightening torque 11 Nm.

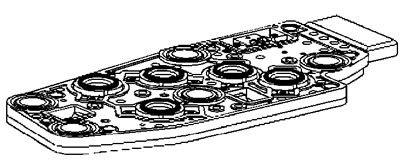

18. Install the inner wire harness to the valve body. The beam casing has a ledge (1). The beam orientation is shown in the figure.

19. Position the lug of the casing between the valve body and the pressure switch in place (2). Press on the wire bundle cover in the bosses (1) And (3) until complete fixation.

20. Install the torque converter clutch pulse width modulation valve.

21. Install the modulation valve retainer.

22. (Modifications) Install the fluid indicator restrictor bracket. Tighten the mounting bolts. Tightening torque 11 Nm.

23. Connect all connectors:

- pressure regulator valve position sensor

- shift valve 1-2 gears

- shift valve 2-3 gears

- pressure control valve

- valve modulation pulse width clutch

- shift valve 3-2 gears.

24. Install the automatic transmission filter.