Attention: parts that can be used again must be marked so that they can be installed in the old place.

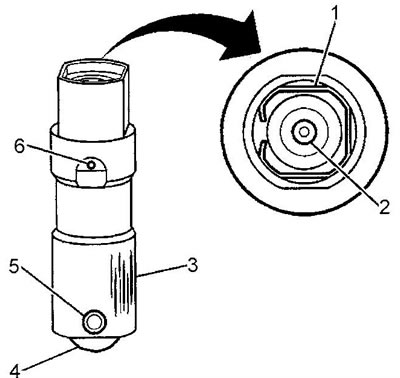

Conventional pushers

1. Wash parts with solvent.

2. Dry parts with compressed air.

3. Inspect the pushers, look for:

- Bent or broken clip (1).

- Signs of wear on the push rod support (2).

- Signs of wear or scuffing of the bearing surface (3), if these defects are present, check the condition of the guide pushers.

- Signs of roller cutting (4).

- Loose fit or damaged latch (5).

- Dirt in the hole (6) oil supply.

- Signs of wear or damage to the roller axle (the roller should rotate freely without jamming).

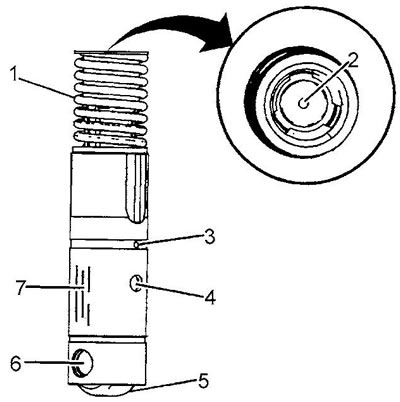

Cylinder shut-off pushers

Attention: parts that can be used again must be marked so that they can be installed in the old place.

1. Wash parts with solvent.

2. Dry parts with compressed air.

3. Inspect the pushers, look for:

- signs of deformation or destruction of the spring (1).

- signs of wear on the push rod support (2).

- dirt in hole (3) oil supply.

- dirt in the oil inlet (4) cylinder shutdown systems.

- roller cut (5).

- signs of wear or damage to the roller axle (the roller should rotate freely without jamming).

- signs of wear or scuffing of the bearing surface (7), if these defects are present, check the condition of the guide pushers.

4. Inspect the pusher guides, look for:

- cracks or damage.

- signs of wear on the guide walls.