2. When boring the cylinders, all crankshaft main bearing caps must be in place, the cap bolts must be tightened to the specified torque.

3. The diameter of the cylinder after boring should be less than the final one by 0.03 mm - this is the allowance for honing the cylinder walls.

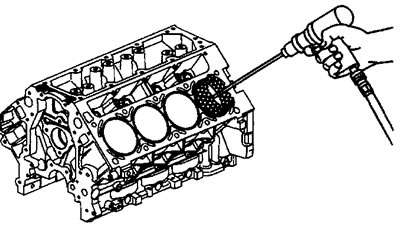

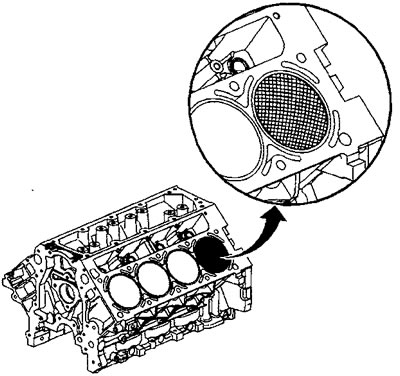

4. It is recommended to honing in two steps, first with relatively coarse 100 mesh stones (0.12 mm), then finally with 220-240 mesh stones (0.05 mm). The hone grid should be located at an angle of 45 degrees to the axis of the cylinder. The tops of the honing marks should be clearly visible, but not have sharp tops (flat top honing).

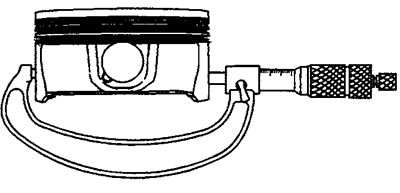

5. After honing, mark the piston with the cylinder number where it will be installed.

6. Thoroughly flush the cylinder walls until the abrasive is completely removed.

7. Lubricate the cylinder walls with clean engine oil to prevent rust.

8. If reboring cylinders to repair size is not required, remove polished areas from the cylinder walls with a hand hone.