Note:

- Excessive clearance between the stem and valve guide can cause noise in the valve train, premature wear of the valve stem seal and consequently increased oil consumption.

- Insufficient clearance can cause valve sticking and damage to other engine parts.

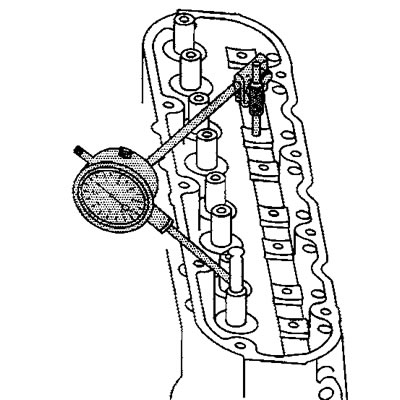

1. Using a dial gauge, measure the clearance between the stem and valve guide. Place the indicator foot on top of the valve guide. When shaking the valve, determine the gap in the pair.

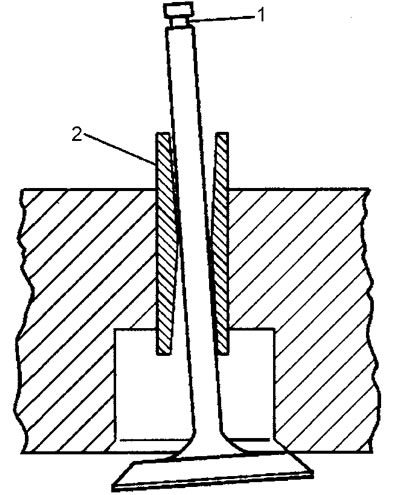

The clearance between the valve stem and guide can also be obtained by directly measuring the outside diameter of the valve stem and the inside diameter of the valve guide. The clearance value is given in the specification. If the valve stem diameter is less than 7.95 mm, the valve must be replaced.

2. If clearance is excessive, replace valve (1) and guide (2) or cylinder head assembly.

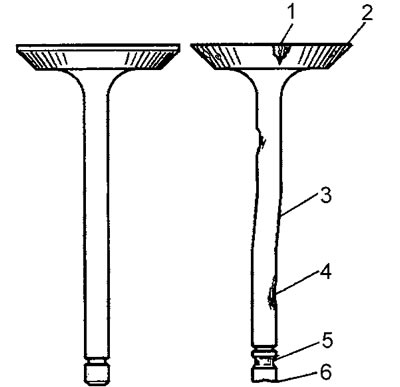

3. Inspect the valves, look for:

- burnout or traces of gas erosion (1)

- signs of a decrease in the thickness of the valve disc (2)

- signs of valve stem deformity (3)

- signs of valve stem wear (4)

- signs of wear of the grooves for the installation of crackers (5)

- signs of stem end wear (6)