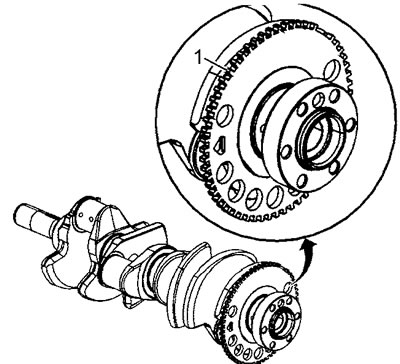

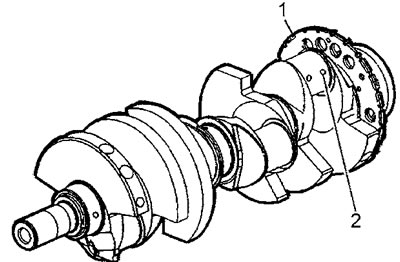

Attention: when repairing the crankshaft, be careful. Avoid damage to the running surfaces of the crankpins, main journals or timing ring teeth (1) crankshaft position sensor. Damage to the teeth of the synchronizing ring can adversely affect the operation of the on-board diagnostic system (OBD) II.

Washing

1. Wash the crankshaft with solvent.

2. Thoroughly clean all oil passages (2) and, if present, deburr the exit channels.

3. Dry the crankshaft with compressed air.

Caution: Wear safety goggles when blowing out the crankshaft.

Examination

1. Check the condition of the teeth of the synchronizing ring of the crankshaft position sensor. For any defect in the teeth, replace the crankshaft.

2. Check up a condition of necks of a cranked shaft. The surface of the necks should be smooth, free of scratches, discoloration, signs of obvious wear, pitting and other damage.

3. Check up a condition of a flange of a cranked shaft in a place of work of a sealing edge of a back epiploon.

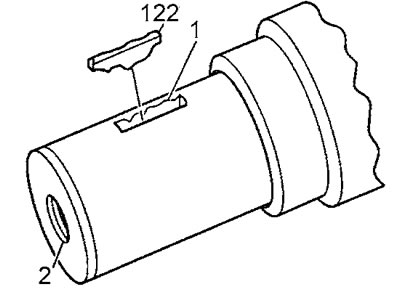

4. Check the condition of the key (122) crankshaft, keyway (1) and threaded hole (2).

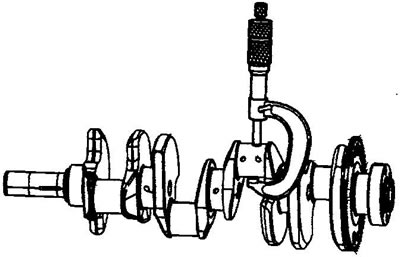

5. Measure the outer diameter of the crankshaft journal in two places along the length of the neck and in two mutually perpendicular planes, determine the taper and ovality of all crankshaft journals.

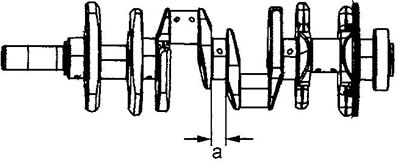

6. Measure the distance (A) between the cheeks of the central main journal for the installation of a thrust bearing. If this distance is greater than 26.2 mm, replace the crankshaft.

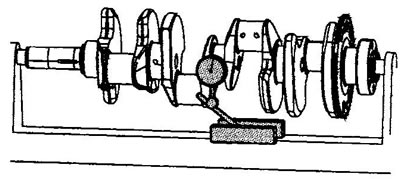

7. Install the shaft on the extreme main journals on V-shaped prisms or in the machine with centers. Measure the crankshaft runout on all main journals, rear flange runout, and timing ring runout.

When measuring the runout of the synchronizing ring, set the indicator leg below the tooth troughs by 1 mm. If the timing ring runout is greater than 0.7 mm, replace the crankshaft.

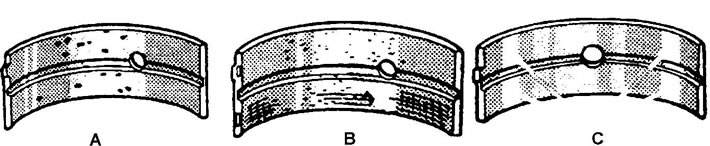

8. Check up a condition of a frictional surface of loose leaves of radical bearings, look for traces of chipping, cracking and other defects. If the bottom is worn or damaged (carrier) bearing, replace both bearings. If the bottom earbud is in good condition, the top one will usually be in good condition as well.

Check of a condition of a frictional surface of loose leaves of radical bearings (to point 8). A - fatigue spalling; B - scoring and tarnish colors, inclusions of foreign material; C - incorrect installation of the liner or defects in the cover or neck (bright polished areas).